Rust-proof anti-corrosive guardrail with coatings

A rust-proof, anti-corrosion, coating technology, applied in the direction of coating, fence, asphalt coating, etc., can solve the problems of unfavorable environmental protection, high cost, containing toxic substances, etc., and achieve the effect of simple structure, reduction of natural aging speed, and low cost.

Inactive Publication Date: 2012-02-08

大连美宸特环保节能产品有限公司

View PDF5 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] The existing guardrails of public facilities are as follows: (1) Made of iron materials, in order to prevent corrosion and rust, the surface is coated with anti-corrosion paint, but the price of anti-corrosion paint is high, it is easy to fall off, and it feels cold in winter. It is not humane enough; it also contains toxic substances, which is not conducive to environmental protection

(2) Made of stainless steel, its disadvantage is that the cost is too high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

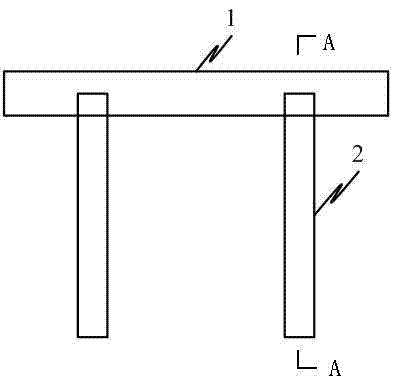

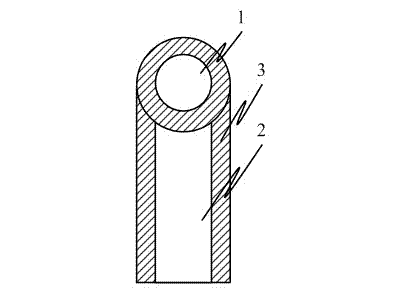

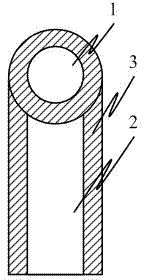

[0014] A coated anti-rust and anti-corrosion guardrail includes a cross bar 1 and a bracket 2, and the surfaces of the cross bar 1 and the support 2 of the anti-rust and anti-corrosion guard rail with coating are sprayed with a liquid rubber spray paint coating 3. The liquid rubber spray paint coating 3 has a thickness of 1-3mm.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a rust-proof anti-corrosive guardrail with coatings, which relates to the technical field of public facilities. The rust-proof anti-corrosive guardrail with the coatings comprises cross bars (1) and a support (2); the rust-proof anti-corrosive guardrail with coating is characterized in that liquid rubber paint coatings are sprayed on surfaces of the cross bars (1) and the support (2) of the rust-proof anti-corrosive guardrail with the coatings. The rust-proof anti-corrosive guardrail has simple structure; the sprayed liquid rubber paint coatings have the properties of low cost, environmental friendliness without simulation, corrosion resistance, rust prevention, fire prevention, flame retardancy, reduction of surface natural aging speed and the like.

Description

technical field [0001] The invention relates to the technical field of public facilities, in particular to a coated antirust and anticorrosion guardrail. Background technique [0002] The existing guardrails of public facilities are as follows: (1) Made of iron materials, in order to prevent corrosion and rust, the surface is coated with anti-corrosion paint, but the price of anti-corrosion paint is high, it is easy to fall off, and it feels cold in winter. It is not humane enough; and it contains toxic substances, which is not conducive to environmental protection. (2) Made of stainless steel, the disadvantage is that the cost is too high. Contents of the invention [0003] In order to solve the above-mentioned problems in the prior art, the present invention provides an anti-rust and anti-corrosion guardrail with coating which is cheap, environmentally friendly, anti-rust and anti-corrosion, beautiful and humanized. [0004] The technical solution adopted by the presen...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E04H17/14E04F11/18E01F15/02E01D19/10C09D195/00C09D121/00

Inventor 马庆海贾天敏康军

Owner 大连美宸特环保节能产品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com