Self-bonding air bag sealing device

A technology of airbag sealing and inner airbag, which is applied in shaft equipment, wellbore lining, tunnel lining, etc., can solve the problems of water leakage, mud leakage, on-site handling difficulties, and easy engineering accidents in the working well, so as to reduce the initial and The effect of reaching the risk, preventing water leakage, and enhancing the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

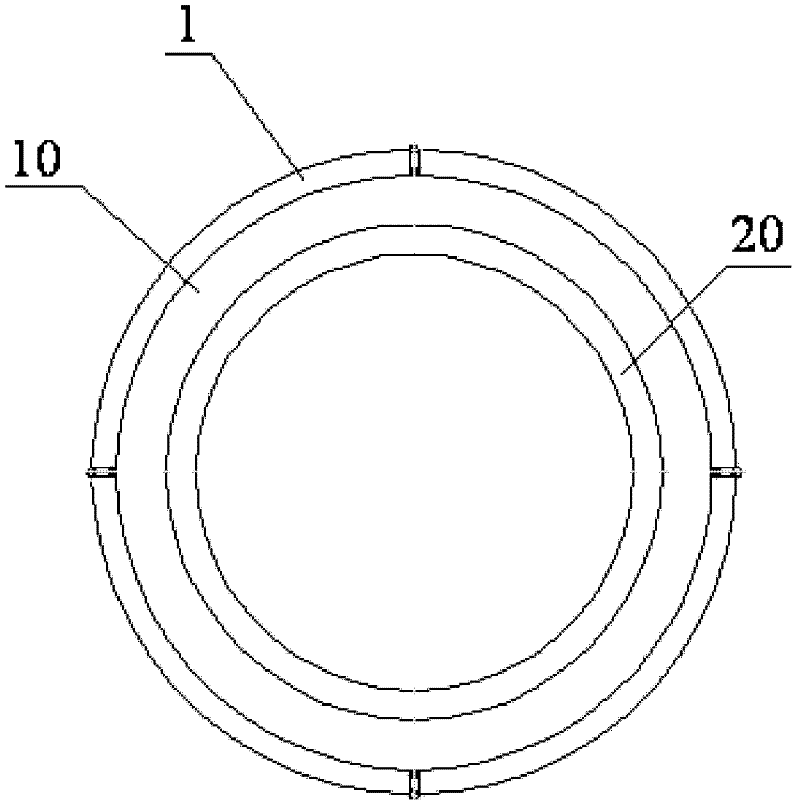

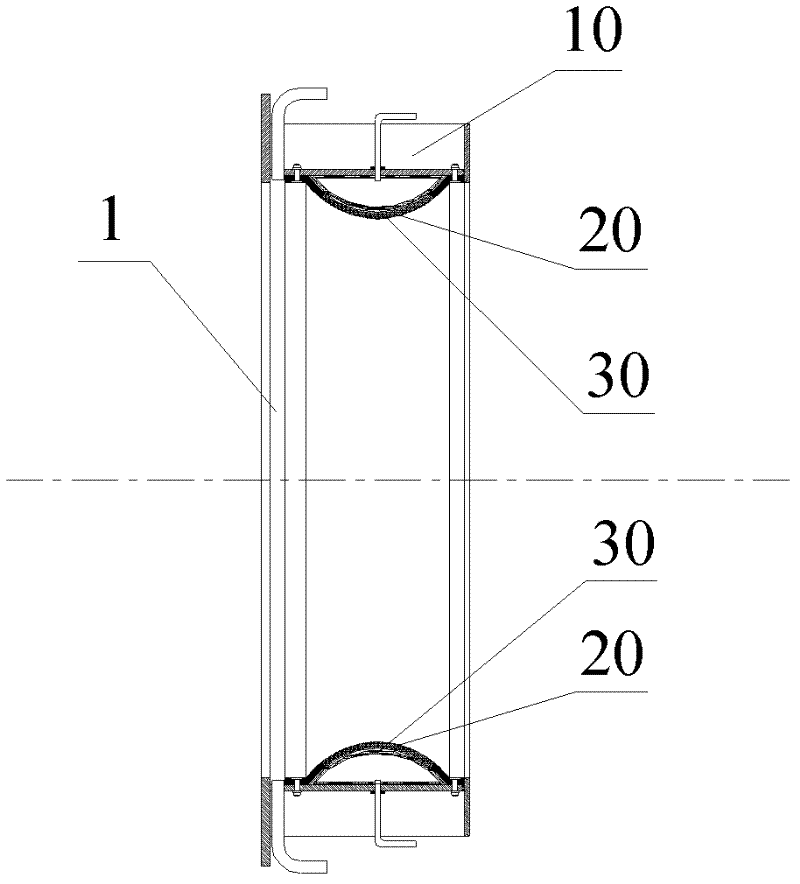

[0022] see figure 1 , figure 2 As shown, the self-holding airbag sealing device 1 of the present invention is a ring-shaped device, which is arranged on the inner well wall of the tunnel working well near the side where the tunnel starts or reaches the door, and its axis coincides with the axis of the door. , which mainly includes a steel collar 10, a U-shaped composite cord rubber guard 20, and a rubber pressure inner airbag 30, the rubber pressure inner airbag 30 is sandwiched between the steel collar 10 and the U-shaped composite cord rubber guard 20 between.

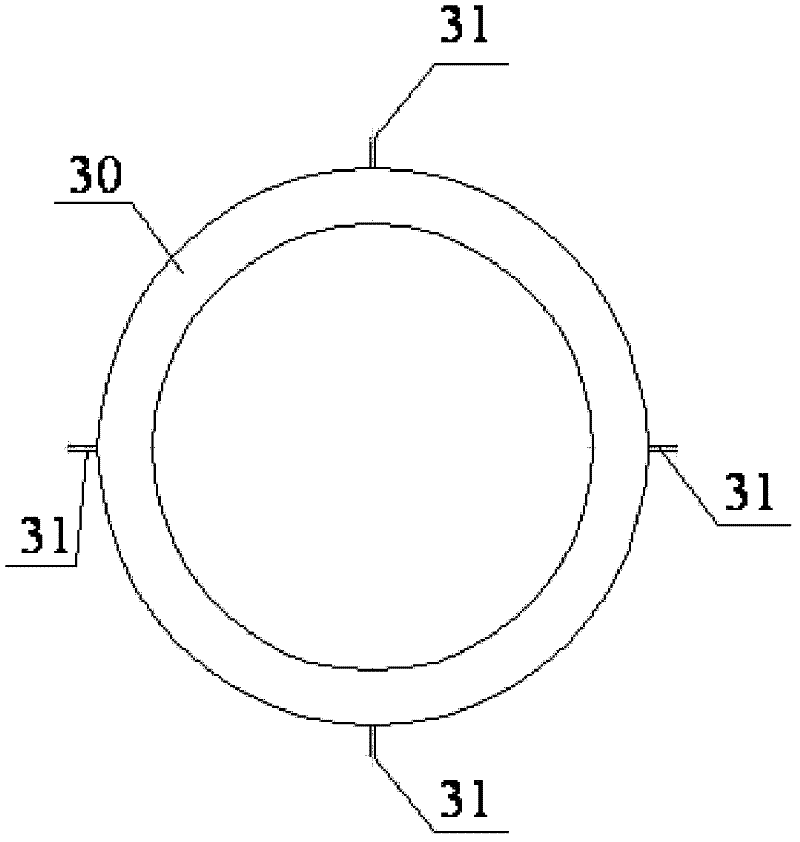

[0023] Cooperate image 3 , Figure 4 As shown, the rubber pressure inner airbag 30 is an annular rubber airbag, and several inlet / exhaust holes 31 are arranged.

[0024] Cooperate figure 2 , Figure 5 As shown, the steel collar 10 includes an annular bottom plate 11, and the annular bottom plate 11 is fixed on the inner side wall of the tunnel working well near the side where the tunnel starts or arrives at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com