Cage-type spring

A technology of cage springs and spring groups, which is applied to springs, springs/shock absorbers, spring components composed of several springs, etc., can solve problems such as high requirements for production equipment, cumbersome production processes, and increased production costs, and achieve Small size, stable compression state, uniform force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

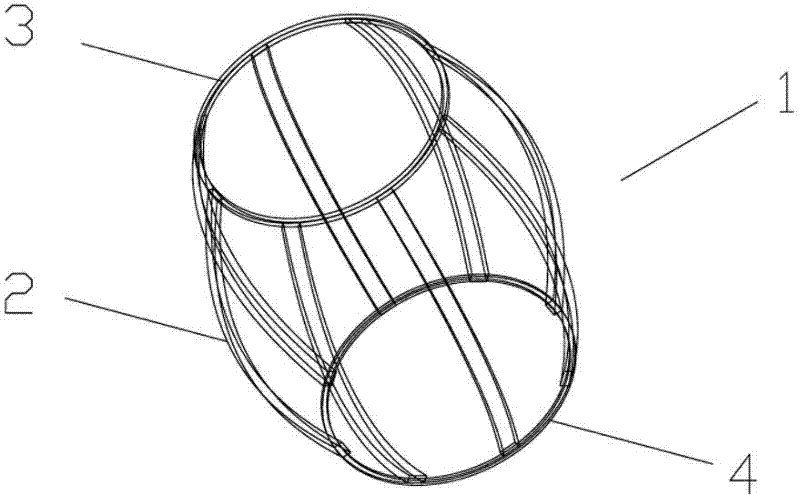

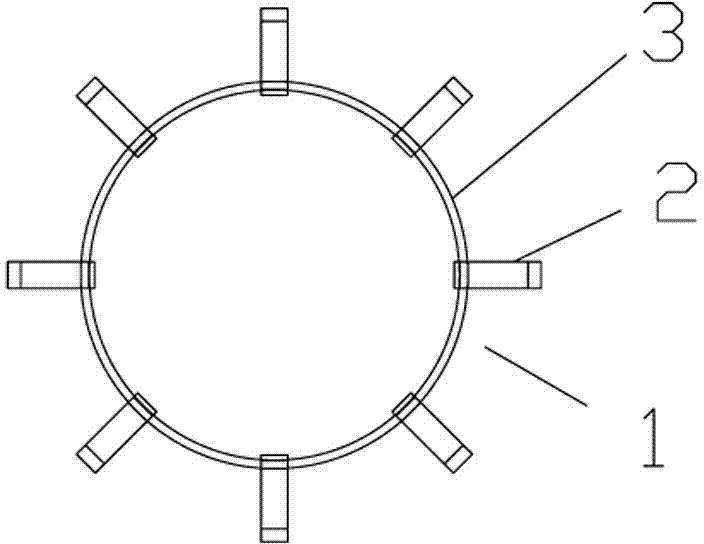

[0022] Embodiment one: refer to Figure 1 to Figure 3 , a cage spring provided by the present invention is simple in structure, small in size, high in bearing capacity, and low in production cost. The cage spring is composed of a section of spring group 1, which includes eight The shrapnel 2, the eight shrapnels 2 are evenly distributed around the center line, so that the force is more balanced, the two ends of the shrapnel 2 are respectively fixed on the upper and lower connecting rings 3, 4, and the shrapnel 2 is bent outward toward the center line . The cage spring in this example is composed of a section of spring group 1. When the spring is under pressure, the shrapnel 2 bends outward under the action of the pressure, and the pressure is shared by eight shrapnel 2. Compared with the traditional single spring coil spring, When the same material is used and the diameter of the spring wire is equal to the diameter of the shrapnel 2, the load that this embodiment can bear is...

Embodiment 2

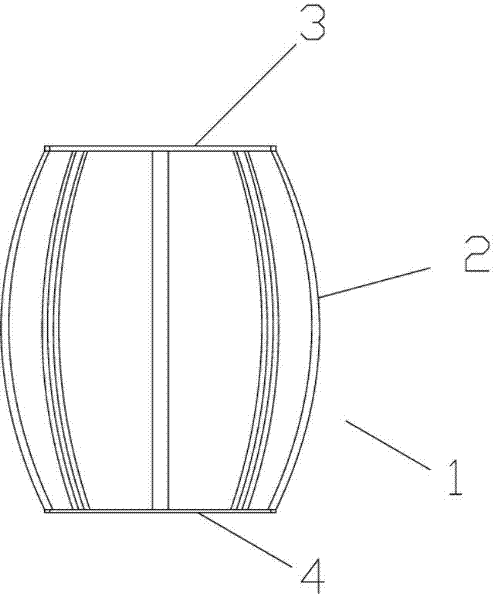

[0023] Embodiment two: refer to Figure 4 , Figure 5 , the structure and principle of this embodiment are basically the same as those of Embodiment 1, the difference lies in: the elastic piece 2 is bent inward toward the center line. That is, when the spring is under pressure, the shrapnel 2 bends inward under the action of the pressure, thereby reducing the volume of the deformed spring and making it more widely used.

Embodiment 3

[0024] Embodiment three: refer to Figure 6 , Figure 7 , the structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that: when the upper connecting ring 3 or the lower connecting ring 4 is small enough or infinitely small, the ends of all the shrapnel 2 are directly connected together, that is One or both ends of the spring are conical to form a conical spring.

[0025] Embodiment three: refer to Figure 8 , Figure 9 , the structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that in this embodiment, the cage spring is composed of four spring groups 1, and each spring group 1 is arranged from top to bottom along the center line . Of course, here, the center line can be not only a straight line, but also a spatial curve, which has the same technical effect and is an equivalent technical solution.

[0026] According to the present invention, the volume, bearing cap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com