Planet reductor brake

A kind of machine brake and planetary deceleration technology, applied in the direction of brake actuator, mechanical equipment, engine components, etc., can solve the problems of restricting the development of construction machinery industry, insufficient radial compression, poor sealing effect, etc., to improve the sealing effect and the performance of the whole machine, reducing the deformation rate, and the effect of small frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

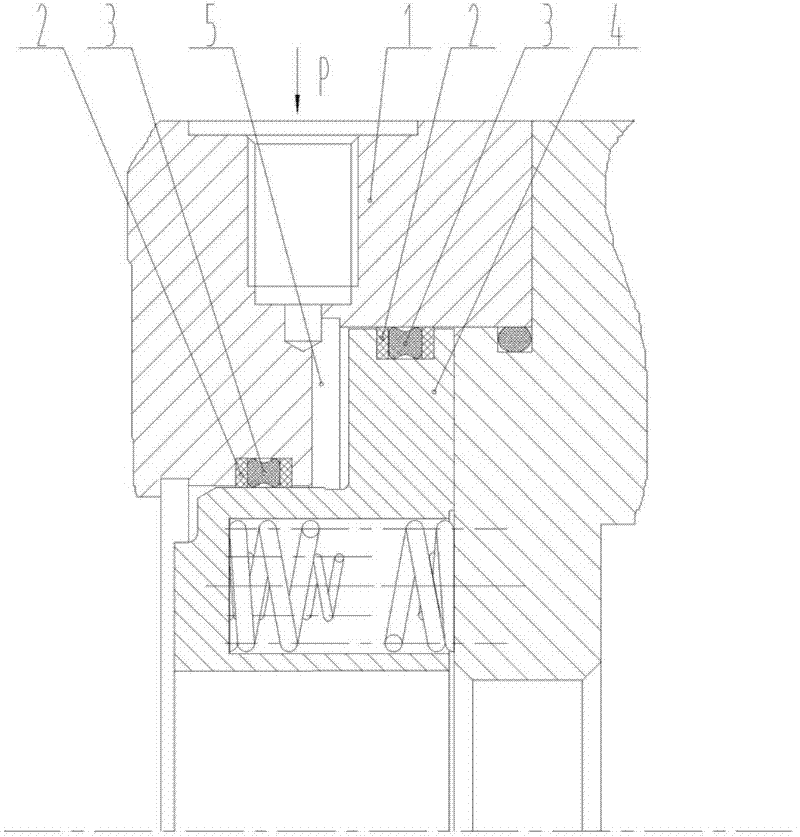

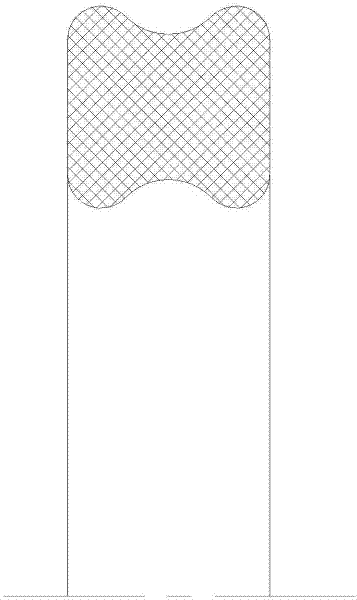

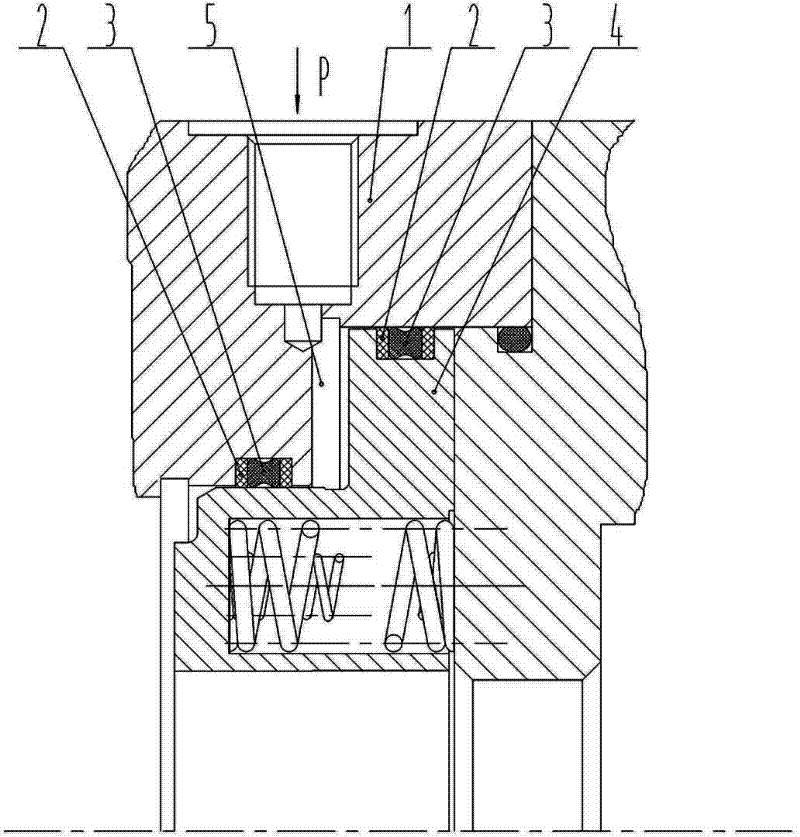

[0011] Below in conjunction with embodiment the present invention is further described. Such as figure 1 , figure 2 As shown, a planetary reduction gear brake, which includes a brake housing 1, a piston 4 is housed in the brake housing 1, a sealed cavity 5 is arranged between the piston 4 and the brake housing 1, and the outer circle of the piston 4 and the brake There is a sealing groove at the joint of the inner wall of the housing 1, and a sealing ring 3 is installed in the sealing groove. The sealing ring 3 is an H-shaped sealing ring. Both axial sides are planes, the cross-section is H-shaped, the lip cross-section is arc-shaped, and there is an arc transition between the lip and the groove. The both sides of described sealing ring 3 have nylon retaining ring 2.

[0012] The H-type sealing ring is a self-tightening sealing ring installed radially. The axial force depends on the pressure P of the system. As the pressure P increases, the radial compression of the H-type...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com