Oil leakage-preventing structure of wind driven generator reductor

A technology for wind power generators and reducers, which is applied to the sealing of engines, engine components, mechanical equipment, etc., can solve the problems that restrict the popularization and application of wind power generation, the structure of reducers is complex, and the replacement is inconvenient, etc., and the effect of preventing oil leakage is good , simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

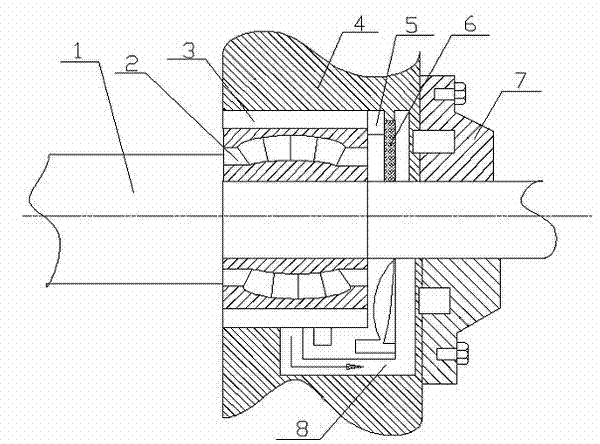

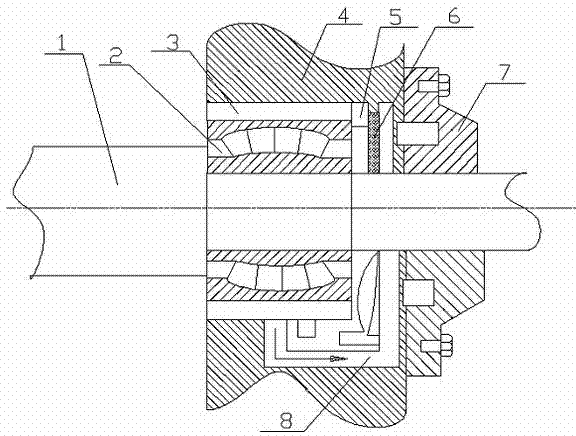

[0008] figure 1 The marks shown are as follows: shaft 1, bearing 2, sealing ring 3, box body 4, stationary ring 5, moving ring 6, flange 7, oil guide groove 8.

[0009] figure 1 The oil leakage prevention structure of the wind turbine reducer shown includes a sealing ring 3, a stationary ring 5, a moving ring 6, and an oil guide groove 8. The bearing 2 is set on the outside of the shaft 1, and the sealing ring 3 is set on the outside of the bearing 2. One end is sleeved with a stationary ring 5, and the stationary ring 5 is externally connected with two moving rings 6. There is an oil guide hole on the outer sealing ring 3 of the bearing 2. The oil guide hole is connected to the oil guide groove 8, and the other end of the oil guide groove 8 is connected to the shaft 1. , The flange 7 is fixed on the box body 4 by bolts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com