Novel refrigeration system with energy system optimization device

A system optimization and refrigeration system technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of high liquid refrigerant temperature, low subcooling degree, and quality to be improved, so as to achieve the optimization and improvement of air conditioning energy system Quality and longevity, the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

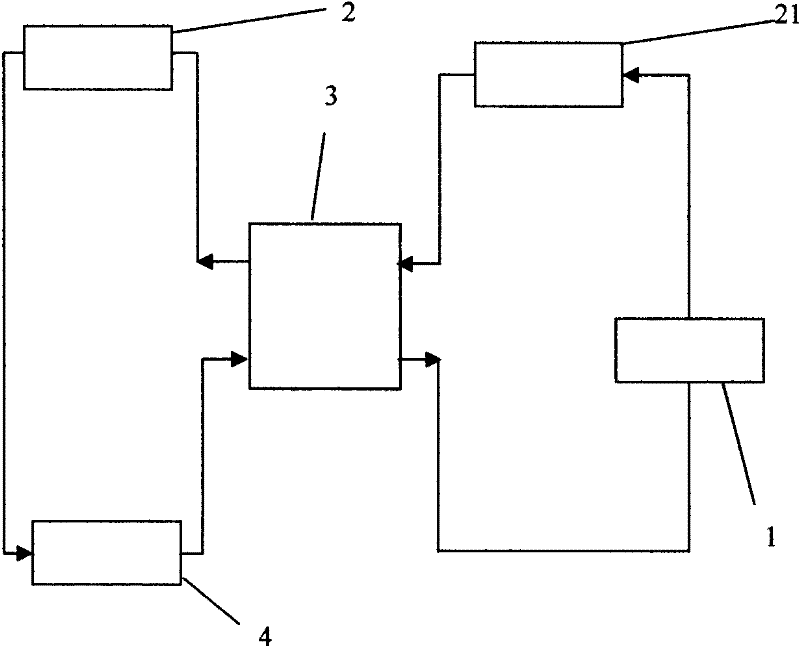

[0015] When retrofitting the existing refrigeration system, an energy system optimization device 3 is added to the traditional refrigeration system circuit. A transmission channel of the energy system optimization device 3 is connected to the condenser 2 or condenser 21 through a refrigerant pipeline, and the energy system Another transmission channel of the optimization device 3 is connected to the outlet of the evaporator 4 through a refrigerant pipeline.

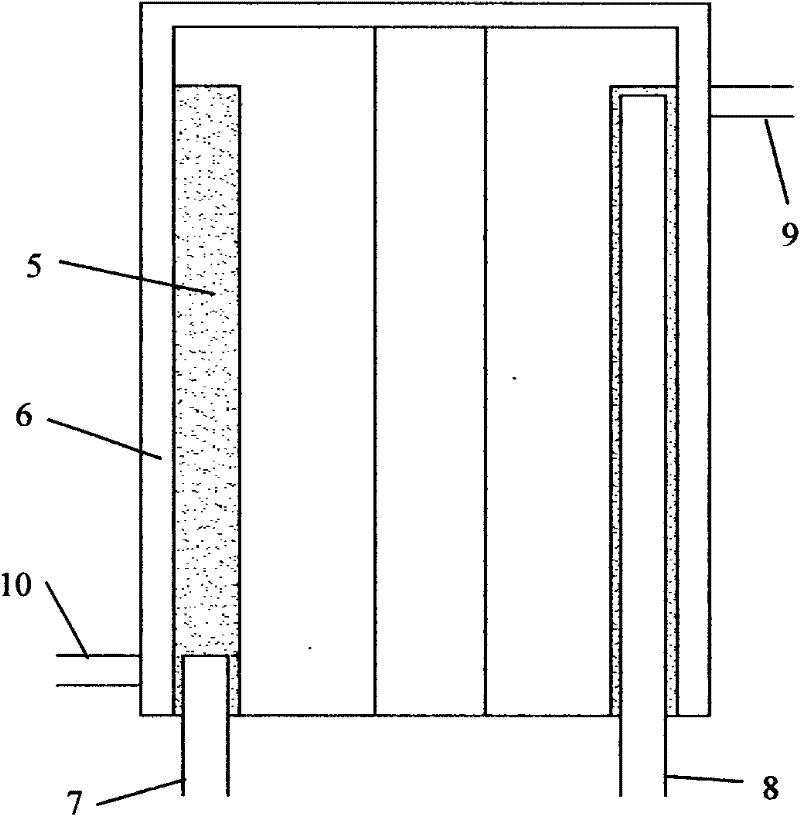

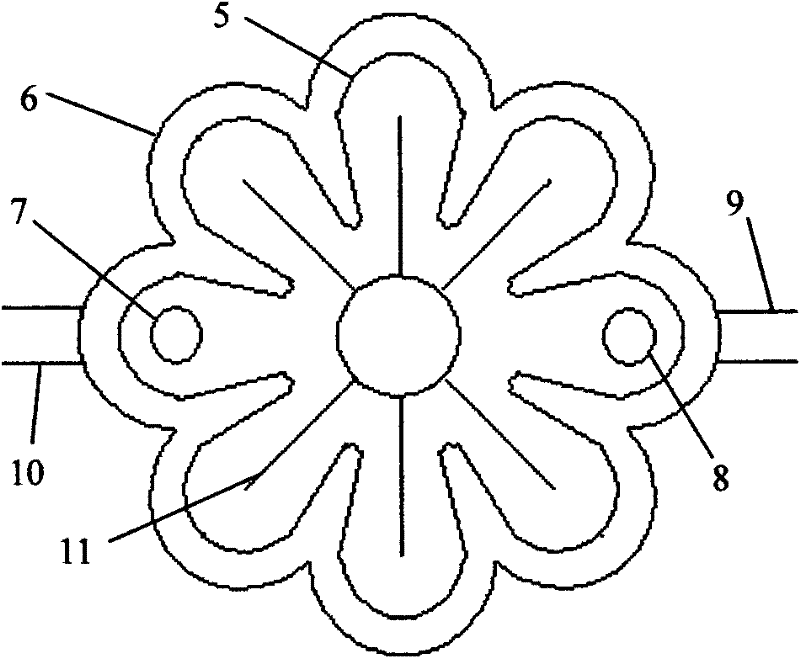

[0016] The gas inlet conduit 7 connected to the evaporator extends into the bottom of the inner layer 5 of the energy system optimization device, the gas outlet conduit 8 is at the top of the inner layer 5 of the energy system optimization device, and the inlet conduit 9 connected to the condenser is located at the outer layer of the energy system optimization device 6, while the liquid outlet conduit 10 is at the top of the outer layer 6 of the energy system optimization device. The purpose of the above approach is to le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com