Electro-catalyst

An electrocatalyst, electrocatalysis technology, applied in electrochemical generators, circuits, fuel cells, etc., can solve the problems of expensive, poor long-term stability, high overpotential and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The catalyst was prepared by the general method disclosed in US4528084 and US4797182. According to these general methods, the support for the catalyst is degreased and etched with dilute acid. Then, a coating containing the desired metal salt or oxide is applied. The carrier is dried and heated in air at about 500°C. If the desired number of paint layers can be applied, they are then dried and heated.

[0048] The PtIr (70:30) catalyst was prepared as follows. The titanium sheet (160×30×1 mm) was degreased and etched (20% HCl, 90° C.), and then cleaned with deionized water. Apply H by coating 2 PtCl 6 and IrCl 3 of aqueous solution. Coating thickness is 5g / m 2 . The titanium sheet is then dried and heated at about 500°C.

[0049] The preparation of the TaIr catalyst is as follows. The titanium sheet (160×30×1 mm) was degreased and etched (20% HCl, 90° C.), and then cleaned with deionized water. Applied by coating with Ta(V) ethoxide and H 2 IrCl 6 organic ...

Embodiment 2

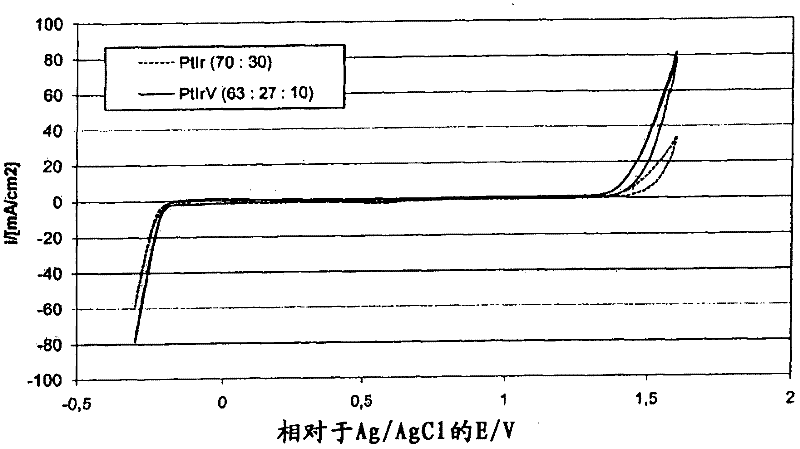

[0052] Cyclic voltammetry measurements were performed on the catalyst composition under the following conditions:

[0053] Electrolyte: H 2 SO 4 (25%w / w)

[0054] Potential: -300 / 1600mV

[0055] Scan speed: 5mV / s

[0056] Temperature: 25°C (in the oven)

[0057] Reference electrode: Ag / AgCl

[0058] Air Flow Through Electrolyte: Yes

[0059] In Table 1 the catalyst composition (on Ti support) and the results are shown.

[0060] Table 1

[0061]

Embodiment 3

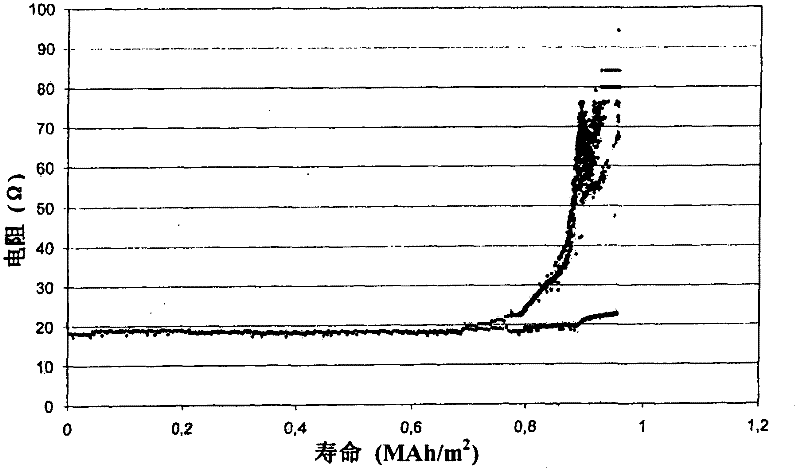

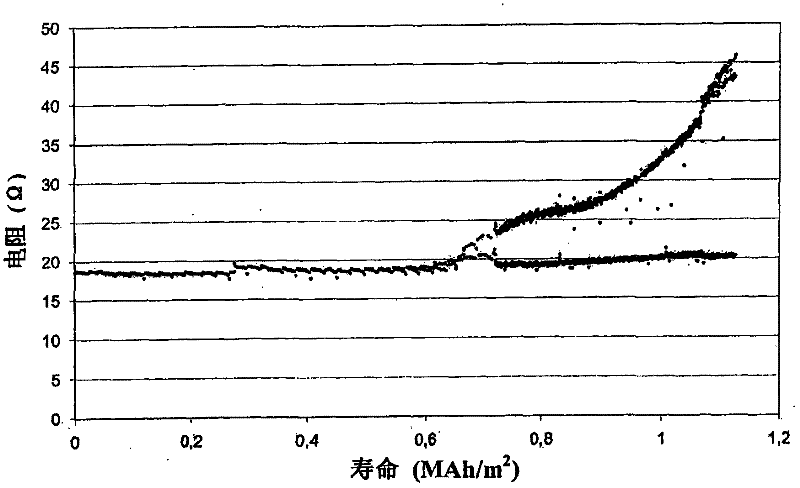

[0063] In the cycle life test, at 2500A / m alternating as anode and cathode (reversing polarity every 5 minutes) 2 The Pt-Ir catalyst (70:30 weight ratio) and the Pt-Ir-V catalyst (69:29:2 weight ratio) on the Ti support were compared at the current density. Tested at 1mol / l Na 2 SO 4 carried out at 50°C.

[0064] Compared with Pt-Ir catalyst, Pt-Ir-V catalyst has higher activity in HER, HOR, ORR, OER (the cycle life of Pt-Ir-V is 1.06MAh / m 2 =102.3kAh / g.m 2 ); the cycle life of Pt-Ir is 0.86MAh / m 2 =80.7kAh / g.m 2 ). The result is as figure 1 and 2 shown. Therefore, the cycle life of Pt-Ir-V is increased by about 27% relative to Pt-Ir (102.3 / 80.7=1.27).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com