Novel use of hydrophobing agent/conductive carbon material composite body

A hydrophobic agent, conductive carbon technology, applied in the direction of catalyst carriers, circuits, electrical components, etc., can solve the problems of low utilization rate of catalyst active particles, electrodes easily flooded, etc., to achieve continuous proton conduction network and reduce transmission. Mass polarization loss, the effect of optimal battery output performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Preparation of catalyst support:

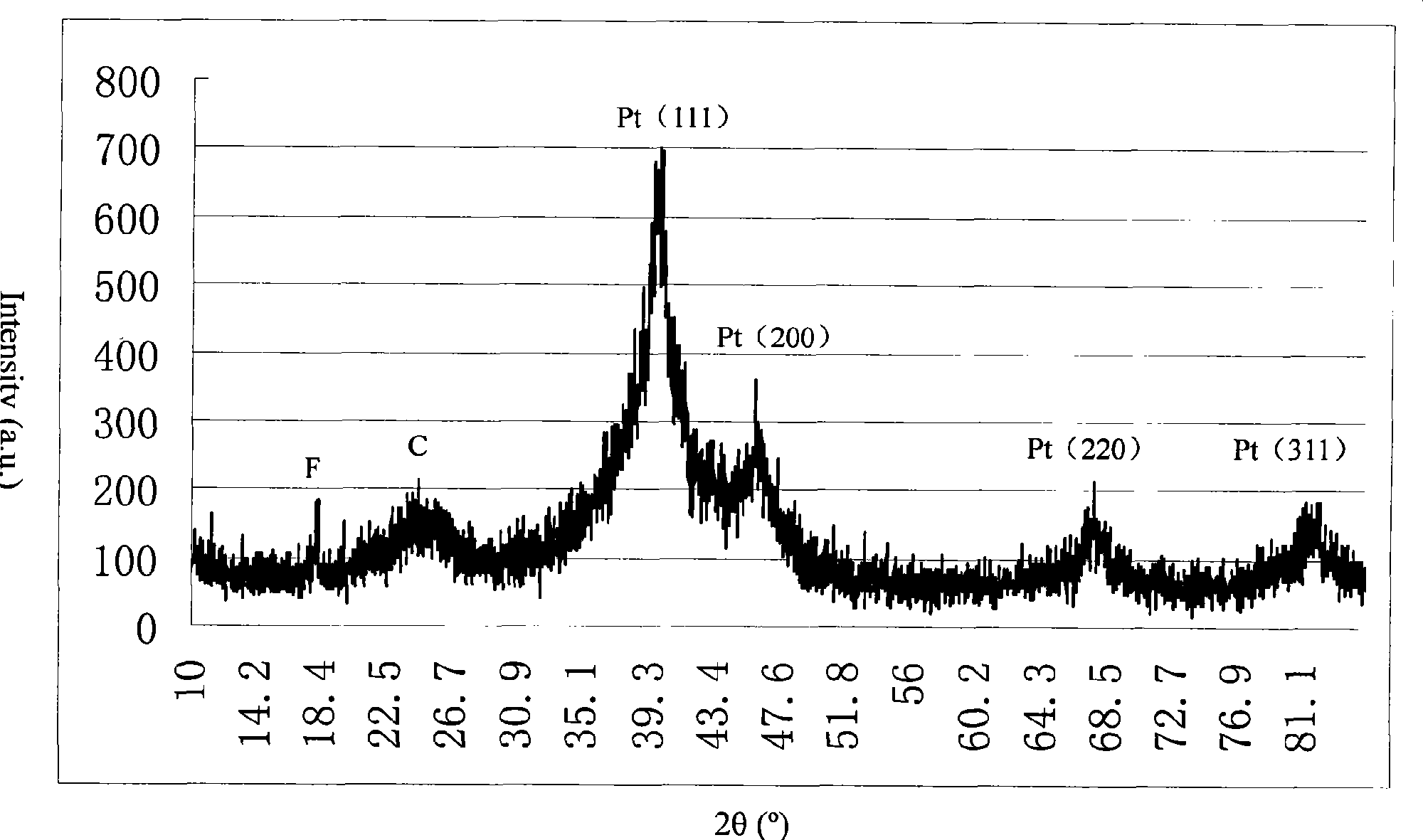

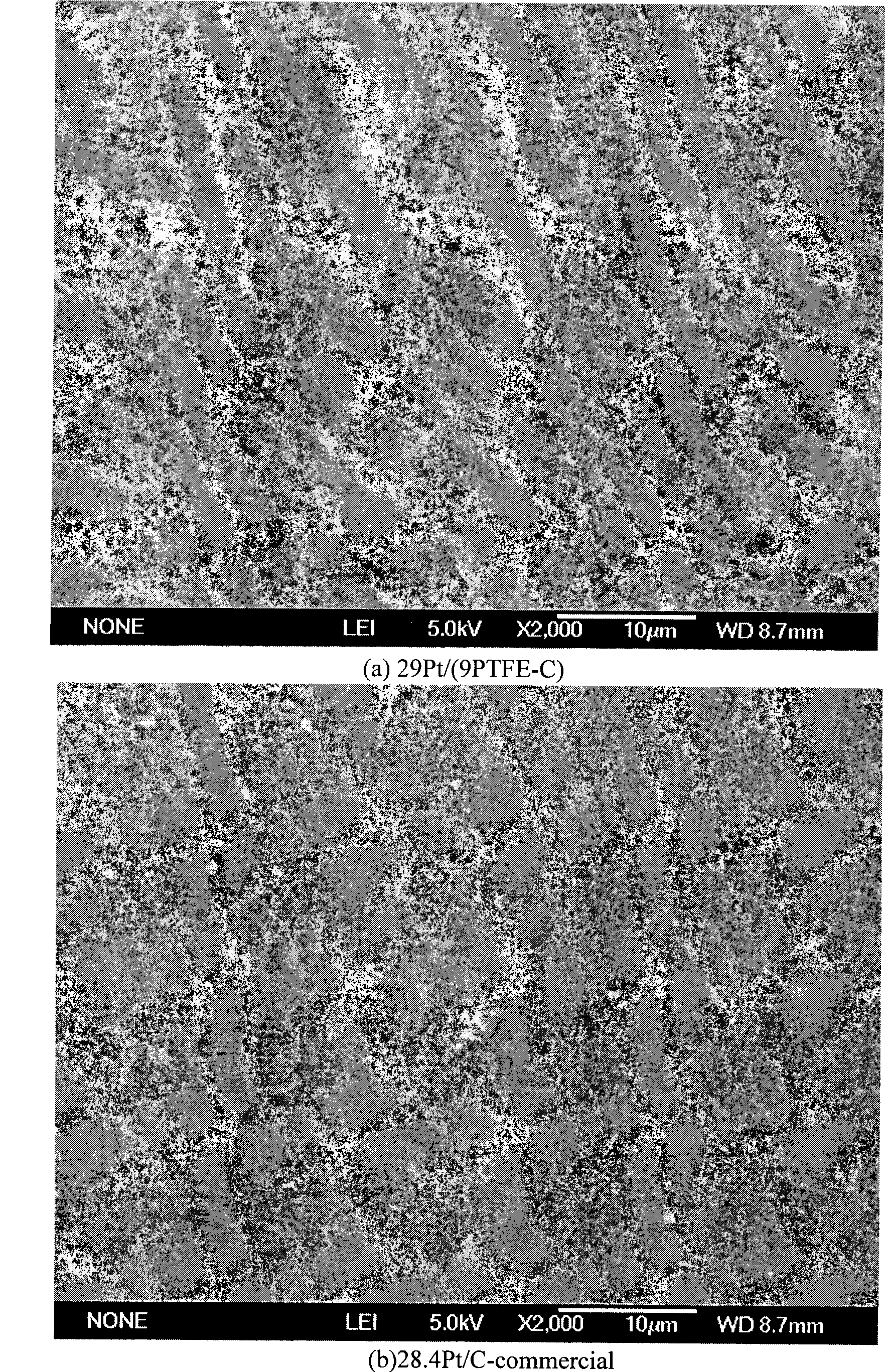

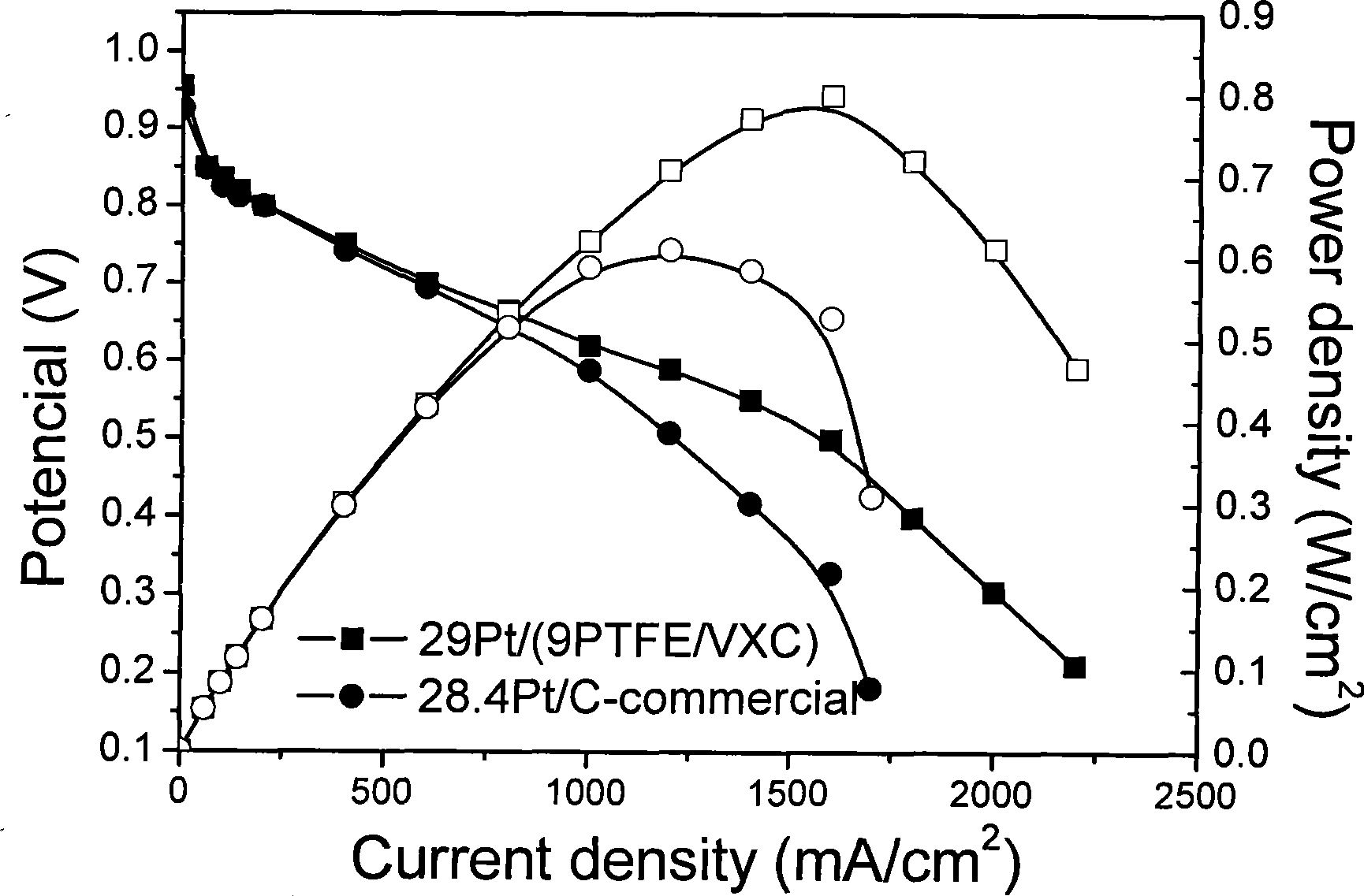

[0052] Take 2.0g VulcanXC-72 conductive carbon black, wet it with 4mL isopropanol solution, add 60mL deionized water, stir mechanically for 15min, and then perform ultrasonic treatment for 30min. Then, under mechanical stirring, 8.6g of 10wt.% PTFE aqueous emulsion was slowly added dropwise, and fully stirred to uniformly mix the carbon black and PTFE. Then place it in a 90°C water bath for coagulation, remove the supernatant, and dry to prepare a PTFE / C composite precursor with a PTFE content of 30wt.%. Put this precursor into a microwave oven (700W, 2450MHz), and perform a heating procedure of microwave heating for 5s and stopping for 20s to remove residual water in the sample. Subsequently, the heating procedure of heating for 10s and stopping for 60s was repeated until the PTFE content was 9wt%. The obtained PTFE / VXC composite powder with a PTFE content of 9 wt%, is denoted as 9PTFE / VXC.

[0053] Catalyst preparation:

[0054] ...

Embodiment 2

[0059] Preparation of catalyst support:

[0060] Take 2.0 g of carbon nanotubes (CNT), wet it with 10 mL of isopropanol solution, add 100 mL of deionized water, stir mechanically for 15 min, and then perform ultrasonic treatment for 30 min. Then, under mechanical stirring, 30 g of 5wt.% FEP aqueous emulsion was slowly added dropwise, and stirred thoroughly, so that the nanotubes and FEP were uniformly mixed. Then place it in a 90°C water bath for coagulation, remove the supernatant, and dry to prepare a FEP / CNT composite precursor with a FEP content of 42wt.%. Put this precursor into a microwave oven (500W, 2450MHz), and perform a heating procedure of microwave heating for 5s and stopping for 20s to remove residual water in the sample. Subsequently, the heating procedure of heating for 15s and stopping for 60s was repeated until the FEP content was 20wt%. A FEP / CNT composite powder with a FEP content of 20 wt % was obtained, which was denoted as 20FEP / CNT.

[0061] Catalyst...

Embodiment 3

[0066] Preparation of catalyst support:

[0067] Take 2.0 g of pearl carbon black (Black Pearls 2000, BP), wet it with 30 mL of isopropanol solution, add 200 mL of deionized water, stir mechanically for 15 min, and then perform ultrasonic treatment for 30 min. Then, under mechanical stirring, 7.1 g of 10wt.% PTFE aqueous emulsion was slowly added dropwise, and stirred thoroughly, so that the pearl carbon black and PTFE were uniformly mixed. Then place it in a 90°C water bath for coagulation, remove the supernatant, and dry to prepare a PTFE / BP composite precursor with a PTFE content of 26wt.%. Put this precursor into a microwave oven (2KW, 2450MHz), and perform a heating procedure of microwave heating for 5s and stopping for 20s to remove residual water in the sample. Subsequently, the heating procedure of heating for 10s and stopping for 20s was repeated until the PTFE content was 15wt%. The obtained PTFE / BP composite powder with a PTFE content of 15 wt%, is denoted as 15PT...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com