Method for plugging conductive holes of circuit boards by resin

A technology of resin plug holes and conductive holes, which is applied in the direction of the electrical connection of printed components, can solve the problems of unqualified circuit board quality, air bubbles, plug hole depressions, etc., and reduce the chance of plug hole depression and bubbles in holes , reduce the distribution density, improve the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

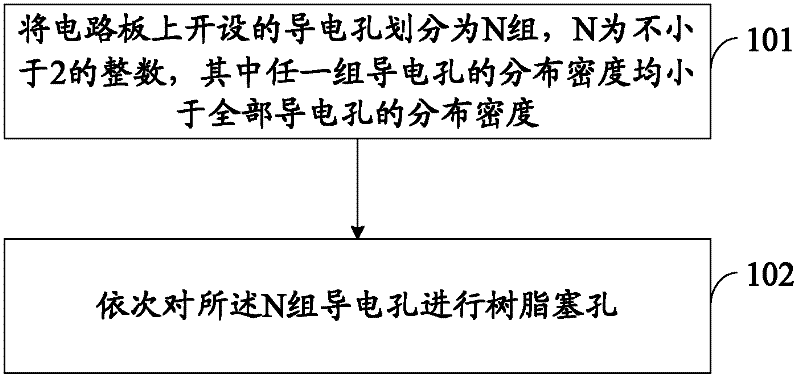

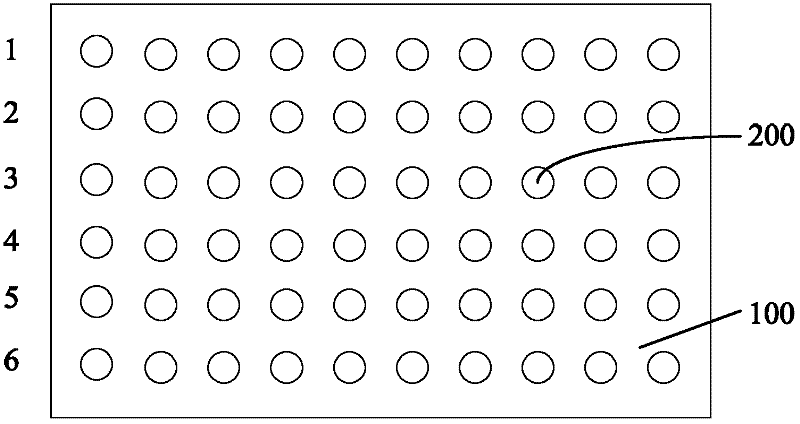

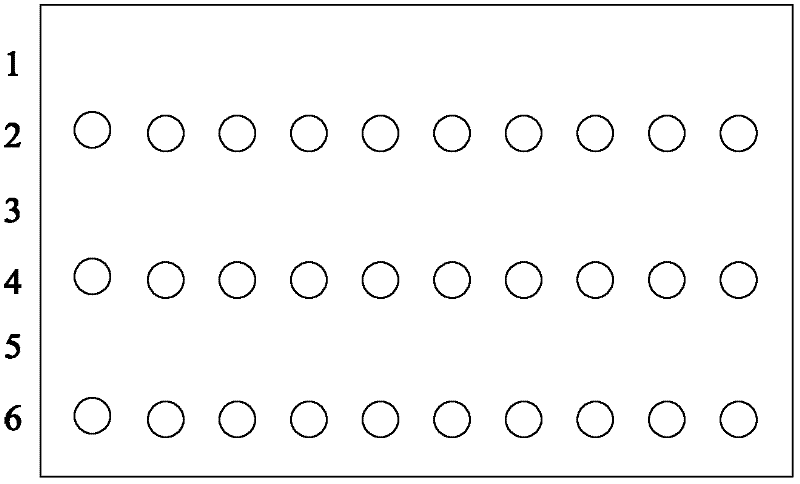

Method used

Image

Examples

other Embodiment approach

[0023] In other implementation manners, there may be more grouping methods, as long as the distribution density of each group of conductive holes can be reduced after grouping, which will not be listed here.

[0024] Generally, before grouping the conductive holes opened on the circuit board, it can also include:

[0025] Conductive holes are opened on the circuit board, and copper sinking and electroplating are performed on the circuit board with conductive holes.

[0026] Among them, mechanical drilling or laser drilling can be used to drill holes in the circuit board, and then be processed according to the general copper sinking and electroplating process, so that a layer of metal is attached to the inner wall of the hole to achieve conduction and become a conductive hole.

[0027] After resin plugging the conductive holes, it can also include:

[0028] The excess resin on the surface of the circuit board is polished, copper sinking and electroplating are performed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com