Water collection pit anti-floating integral formwork system and installing method for formwork system

A technology of formwork system and installation method, which is applied in the direction of construction and infrastructure engineering, can solve the problems of large quantity and density requirements, affecting the quality of concrete molding, and the inability to vibrate concrete, so as to reduce the installation strength and make the quality easier to control. The effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

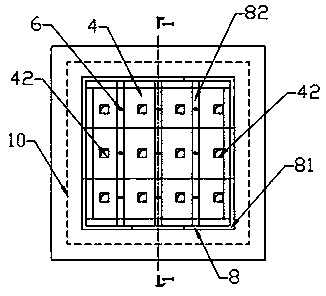

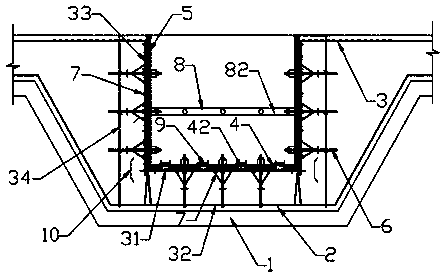

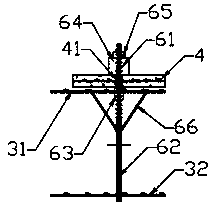

[0026]As shown in the figure, this embodiment provides a sump anti-floating integrated formwork system, which includes a coverless box-shaped formwork assembled from a plurality of side forms 5 and bottom forms 4 and placed in the box-shaped formwork. The support system 8, the bottom form 4 and the side form 5 are respectively fixedly installed on the bottom reinforcement and the side reinforcement of the reinforcement support 3, and the bottom form 4 and the side form 5 are concrete prefabricated slabs with reinforcement mesh inside, and Between the bottom form 4 and the bottom steel bar, between the side form 5 and the side steel bars, a plurality of segmented water stop screws 6 distributed in a lattice shape are installed; A plurality of vibrating holes 42 are evenly distributed among them, and the vibrating holes 42 are rectangular, and the distance between adjacent vibrating holes 42 is 500-800mm, and the specific distance needs to be set according to the effective vibrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com