Non-contact type three-dimensional scanner based on micro mirror

A non-contact, micro-mirror technology, applied in the direction of sewing tools, etc., can solve the problems of large data collection and calculation, cumbersome calibration process, inconvenient operation, etc., to achieve simple operation, high scanning frequency, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

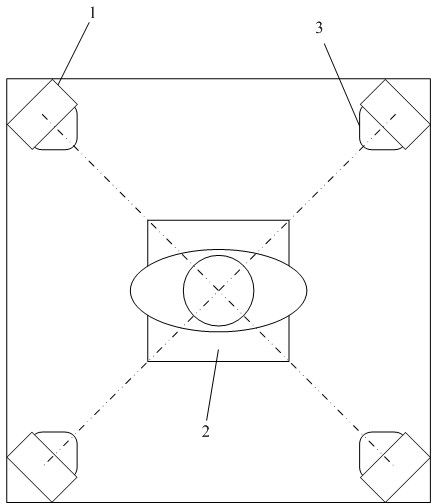

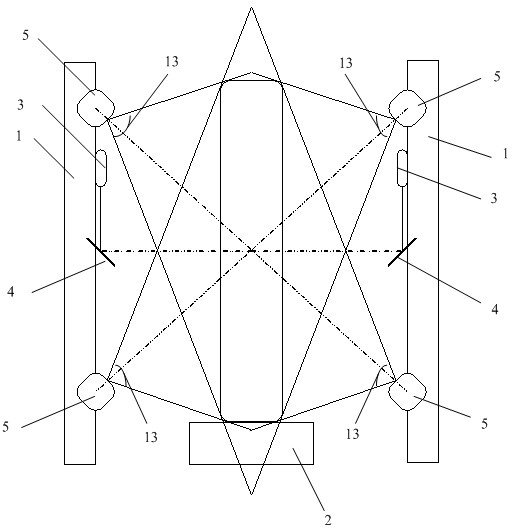

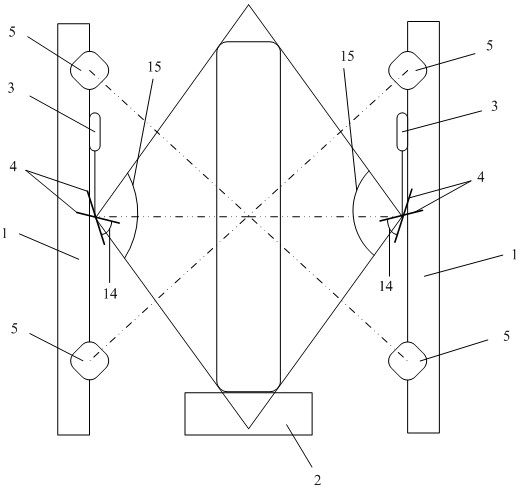

[0014] Such as Figure 1 to Figure 3 As shown, a non-contact three-dimensional anthropometric device based on micro-mirrors provided by the present invention mainly includes four columns 1, a measuring table 2, four line laser generators 3, and four reflective MOEMS micro-scanning mirrors 4. Eight industrial cameras 5, four columns 1 are distributed in a square, the columns 1 are respectively located at the four vertices of the square, and the center of the measuring platform 2 overlaps with the intersection of the diagonals of the square. A line laser generator 3, a reflective MOEMS micro-scanning mirror 4 and two industrial cameras 5 are installed on each column 1. The two industrial cameras 5 on the column 1 are placed symmetrically at a specific angle relative to the reflective MOEMS micro-scanning mirror 4, and the position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com