Non-meshing double-mixing rotor for continuous internal mixer

A mixing rotor, non-meshing technology, applied in the field of double mixing rotors for materials in continuous internal mixers, can solve problems such as difficulty in dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

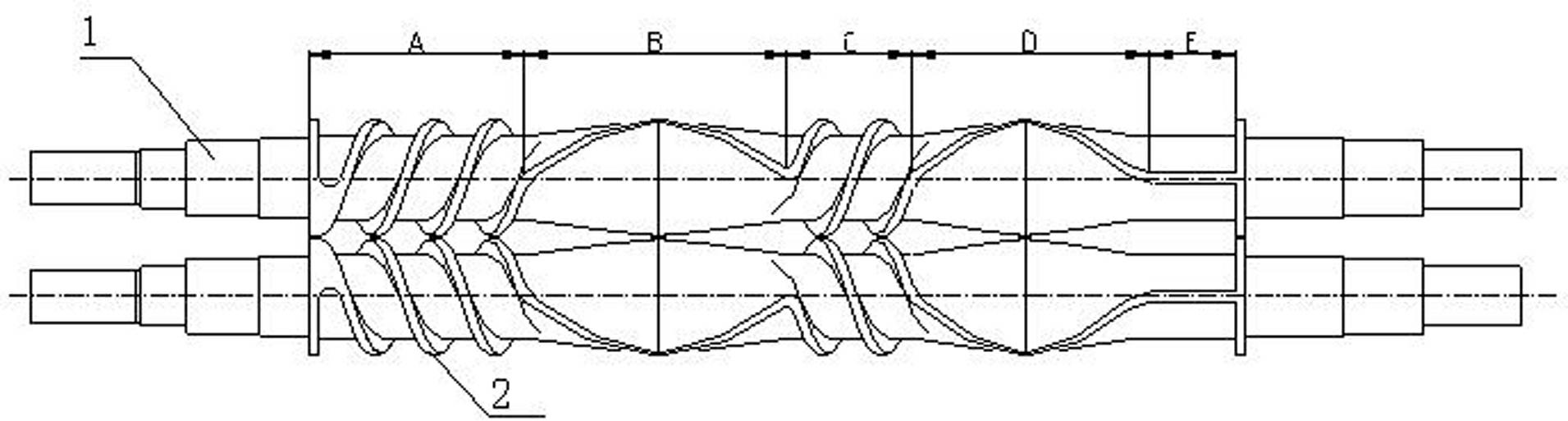

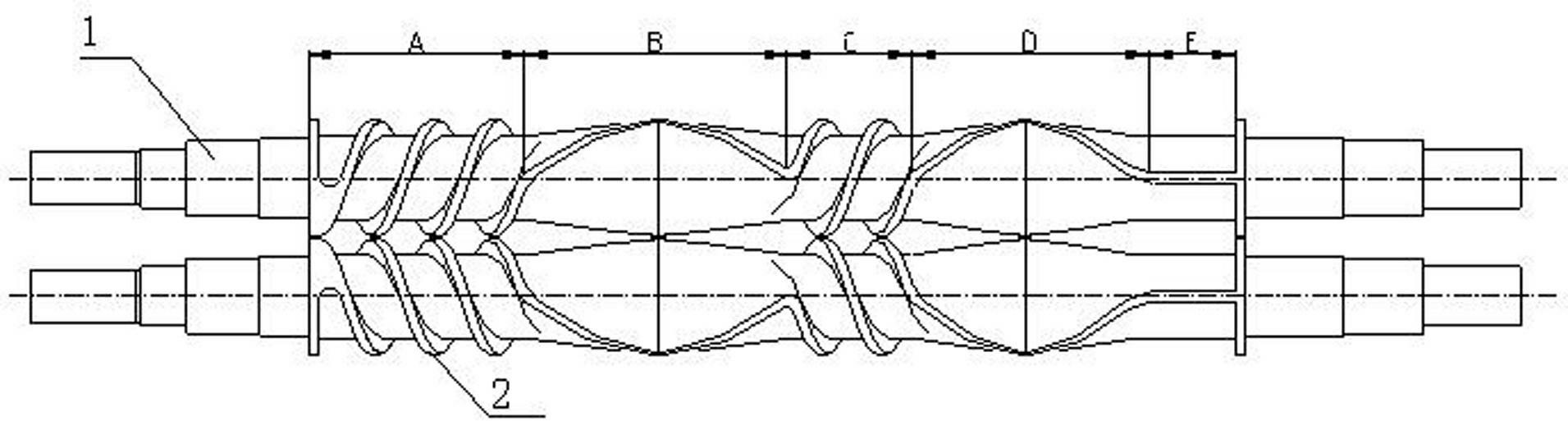

[0015] see figure 1 , the non-meshing double-mixing rotor for continuous internal mixer of the present invention is a non-meshing rotor, comprising a pair of relatively rotating rotor bodies 1, and each rotor body 1 is respectively provided with a The discharge section E, the material conveying section A arranged at the other end of the rotor body 1, and the additive adding section C arranged in the middle section of the rotor body 1, and the first banburying section B is arranged between the material conveying section A and the additive adding section C , for the dispersion and preheating of materials; between the discharge section E and the additive adding section C, there is a second banburying section D for melting and mixing of materials; the first banburying section B and the second banburying section D Both are double-ended positive and negative threads, which are used for dispersing and preheating materials.

[0016] In this embodiment, the double-head forward and rev...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap