Bundling tube for microwave oven

A technology of microwave heating furnace and bundled tubes, which is applied in the direction of roads, road repairs, roads, etc., can solve the problems of microwave generators being easily damaged, the amount of heating material increased, and the volume increased, and achieve short heating time, uniform heating temperature, The effect of energy concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

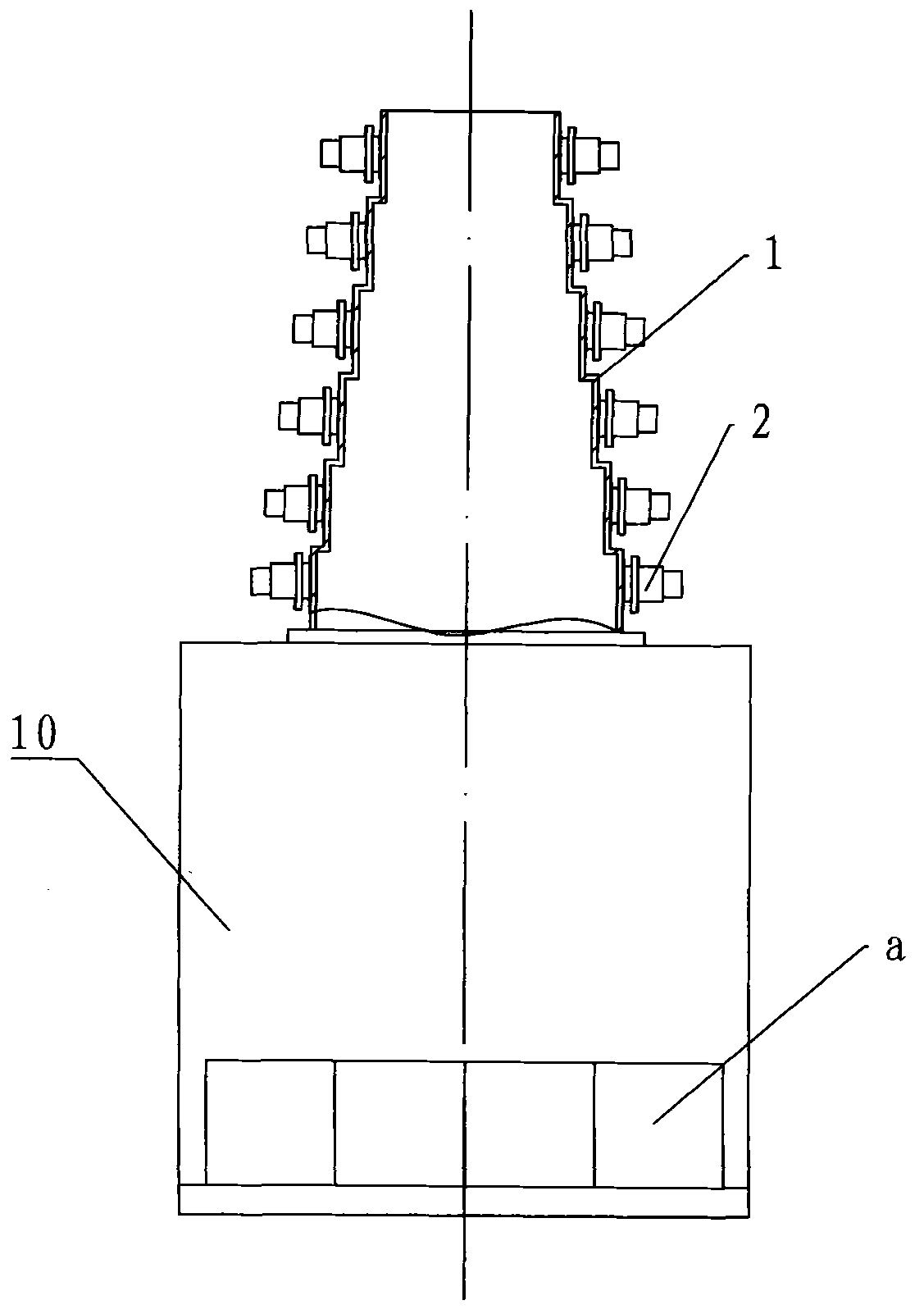

[0022] Such as figure 1 As shown, the bundle tube used in the microwave heating furnace of this embodiment is installed on the top wall of the microwave heating furnace 10 , and the material a to be heated is placed in the microwave heating furnace 10 . This bundle tube for microwave heating furnace comprises main body 1 and microwave generator 2, main body 1 is a hollow shape structure, is equipped with a plurality of microwave generators 2 at intervals on main body 1 peripheral wall, the outer contour shape of main body 1 of the present invention In order to reduce forward along the center line, that is, the emission end of the microwave generator 2 on the main body 1 is defined as the front, the open end of the bundle tube is defined as the rear end, the front end of the main body 1 is smaller than the rear end size, and the main body 1 is from the rear to the rear end. The front is generally convergent, and the outer contour of the main body 1 can be continuously tapered a...

Embodiment 2

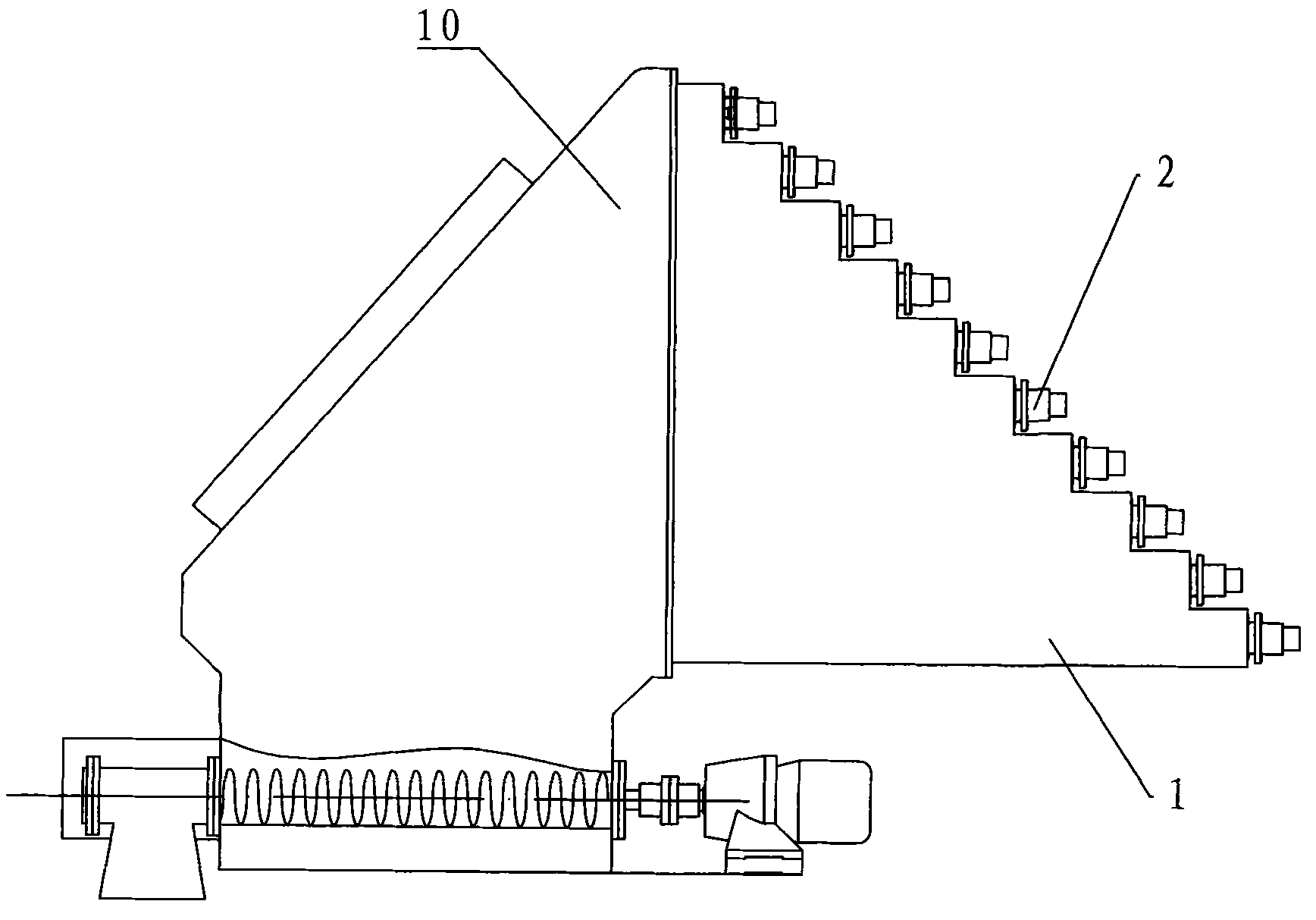

[0024] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the cluster tubes are installed on the side wall of the trapezoidal microwave heating furnace 10, and the inner bottom of the microwave heating furnace 10 is equipped with a discharge device driven by a motor, and the main body 1 is a There is a quadrilateral with a stepped side wall, the vertical section shape of the side wall opposite to the microwave heating furnace 10 of the quadrilateral is stepped, the outlet of the main body 1 is opposite to the stepped side wall, and the quadrilateral is viewed from the vertical section. Seen as an asymmetric structure, the microwave generator 2 is installed on the side wall of the main body 1 opposite to the microwave heating furnace 10, and each step surface on the side wall forms the installation surface of the microwave generator 2, and the stepped structure is convenient The installation of the microwave generator 2 is also easier to...

Embodiment 3

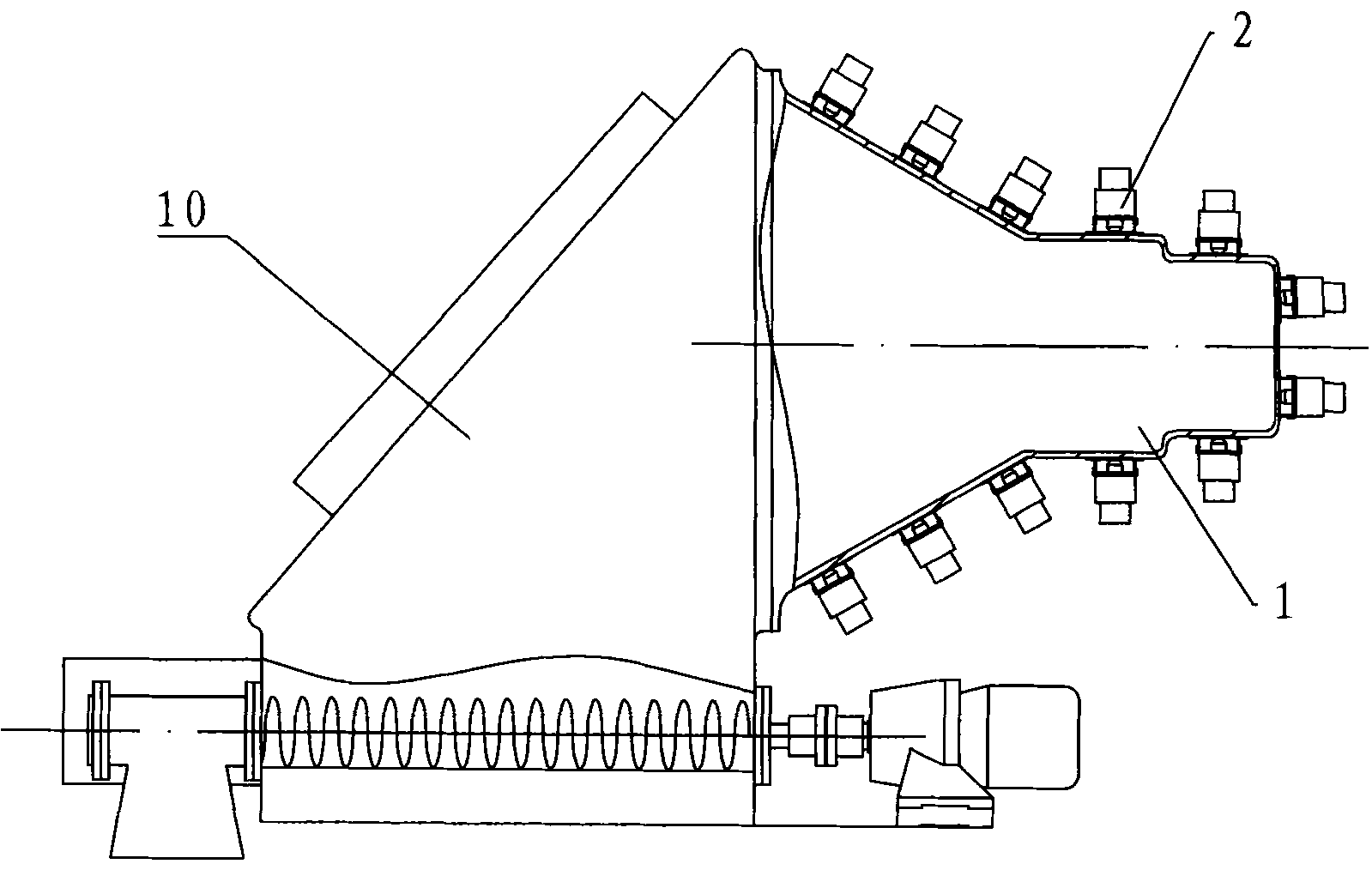

[0026] Such as image 3 As shown, the main body 1 of this embodiment is similar to the main body 1 in the first embodiment, and both of them have a symmetrical structure along the center line. The line is folded and reduced to form a stepped surface. The outer contour of the rear part of the main body 1 is continuously tapered along the center line. The microwave generators 2 are installed on the outer peripheral wall of the main body 1 at intervals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com