Environment-friendly method for filling liquid nitrogen and liquid argon

An environmentally friendly filling technology, applied in container filling methods, equipment loaded into pressure vessels, gas/liquid distribution and storage, etc., can solve problems such as waste, customer economic loss, noise pollution, etc., to avoid waste, solve Noise pollution and waste, easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

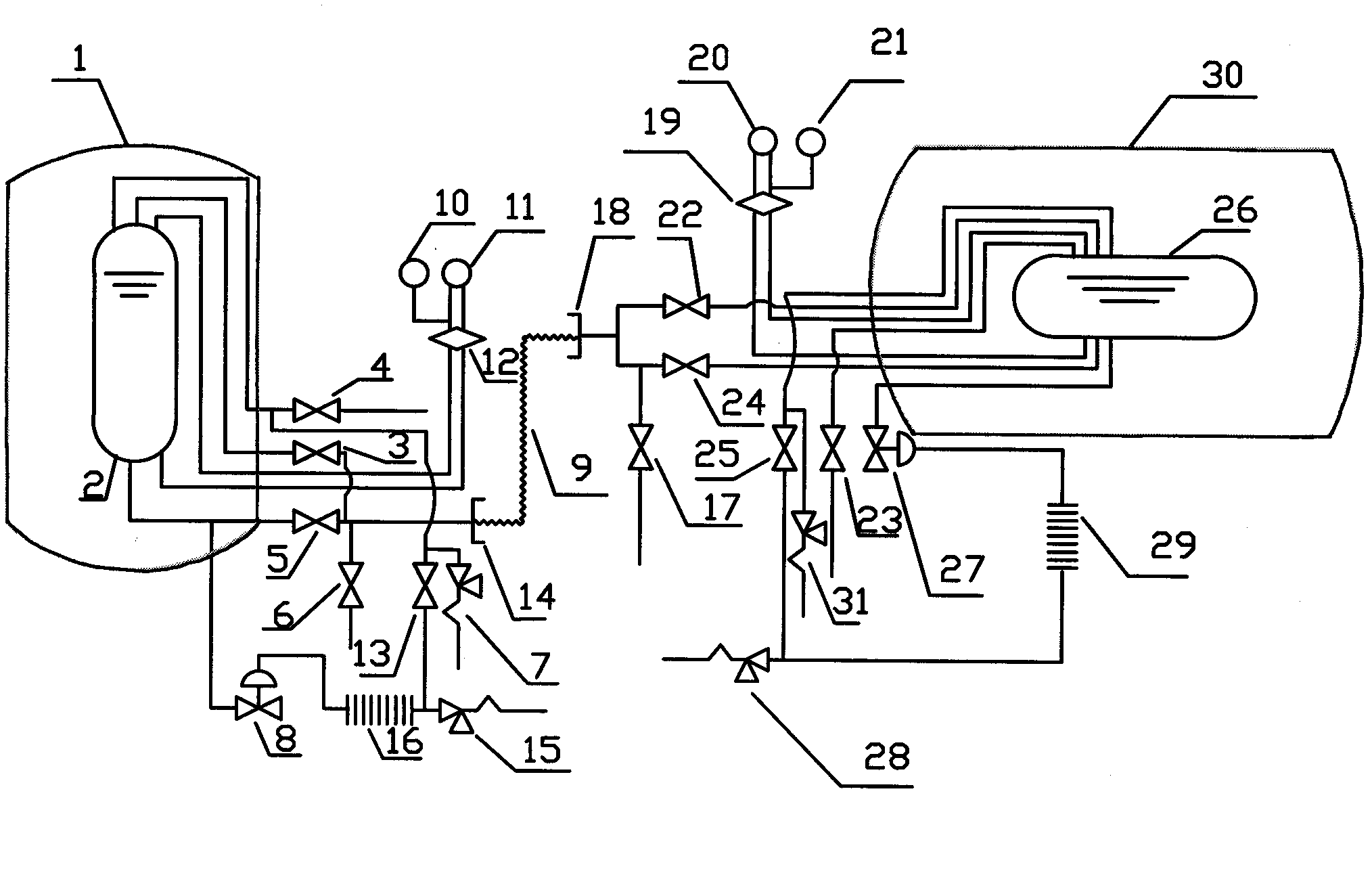

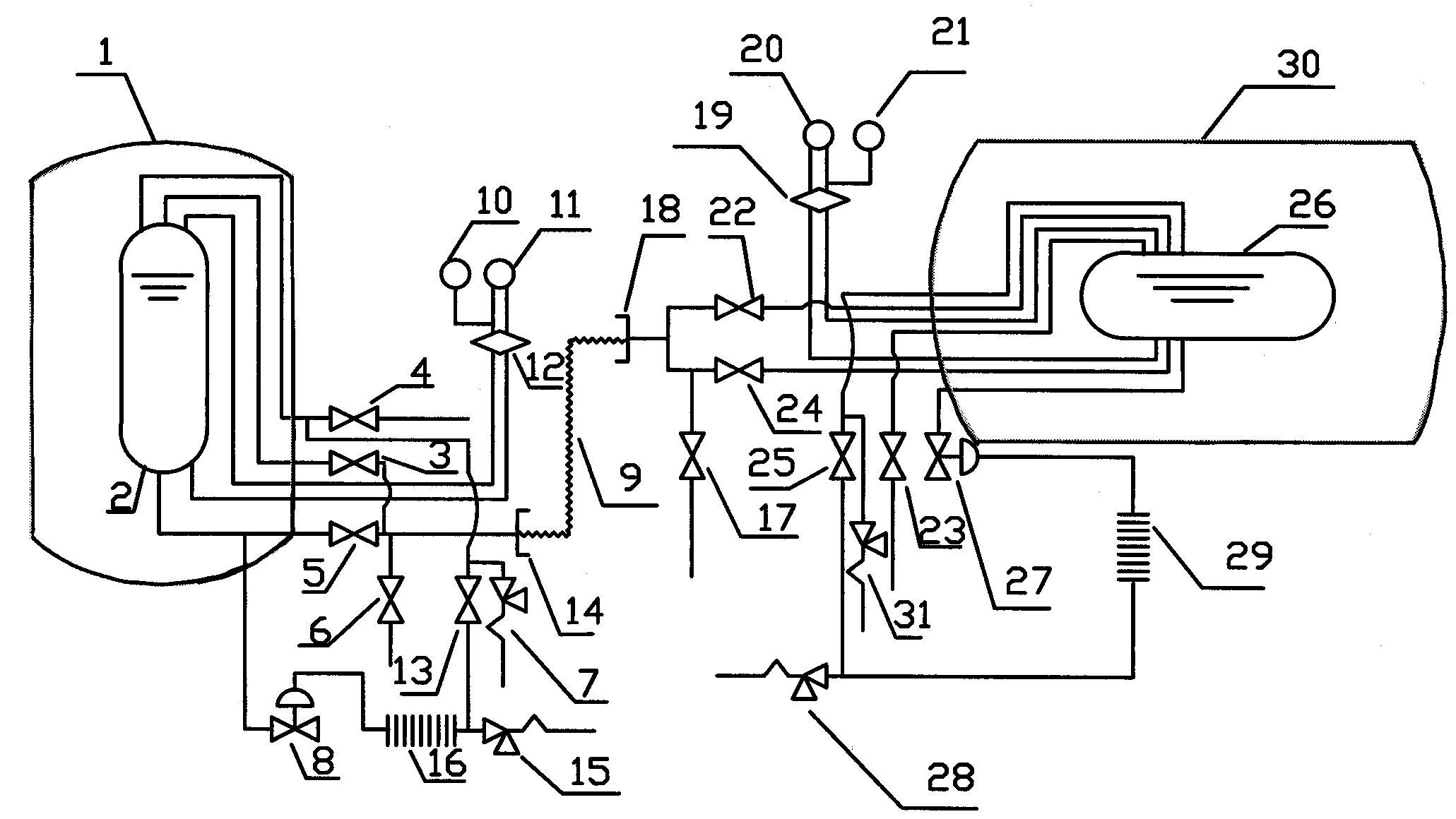

[0024] See figure 1 The filling interface 14 on the low-temperature storage tank 1 used by the customer is connected with the filling interface 18 on the tank car 30 that the manufacturer sends the low-temperature liquid through the infusion pipeline 9, in order to transport the low-temperature liquid in the tank car 30 to the customer in storage tank 1. The cryogenic liquid is only stored in the inner tank 2 of the storage tank 1 and the inner tank 26 of the tank car 30. Normally, the upper part of the inner tank 2 and the inner tank 26 is a low-temperature gas, and the lower part is a cryogenic liquid. Customers can choose according to actual needs. Choose to use liquid or gaseous gases. The storage tank 1 and the tank car 30 have the same structure, both of which are composed of an inner tank and an outer tank. There is a vacuum between the inner tank and the outer tank to achieve the effect of heat insulation, prevent heat from invading from the outside, and prevent the p...

Embodiment 2

[0034] See figure 1 The filling interface 14 on the low-temperature storage tank 1 used by the customer is connected with the filling interface 18 on the tank car 30 that the manufacturer sends the low-temperature liquid through the infusion pipeline 9, in order to transport the low-temperature liquid in the tank car 30 to the customer in storage tank 1. The cryogenic liquid is only stored in the inner tank 2 of the storage tank 1 and the inner tank 26 of the tank car 30. Normally, the upper part of the inner tank 2 and the inner tank 26 is a low-temperature gas, and the lower part is a cryogenic liquid. Customers can choose according to actual needs. Choose to use liquid or gaseous gases. The storage tank 1 and the tank car 30 have the same structure, both of which are composed of an inner tank and an outer tank. There is a vacuum between the inner tank and the outer tank to achieve the effect of heat insulation, prevent heat from invading from the outside, and prevent the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com