Automated testing system and method for index parameters of fiber optic gyro

An automated testing and fiber optic gyro technology, applied in measurement devices, instruments, etc., can solve the problems of unintuitive test results, low degree of automation, and low test data accuracy, and achieve simple and easy test operation, improve the degree of automation, and shorten the test. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is described in detail below in conjunction with accompanying drawing:

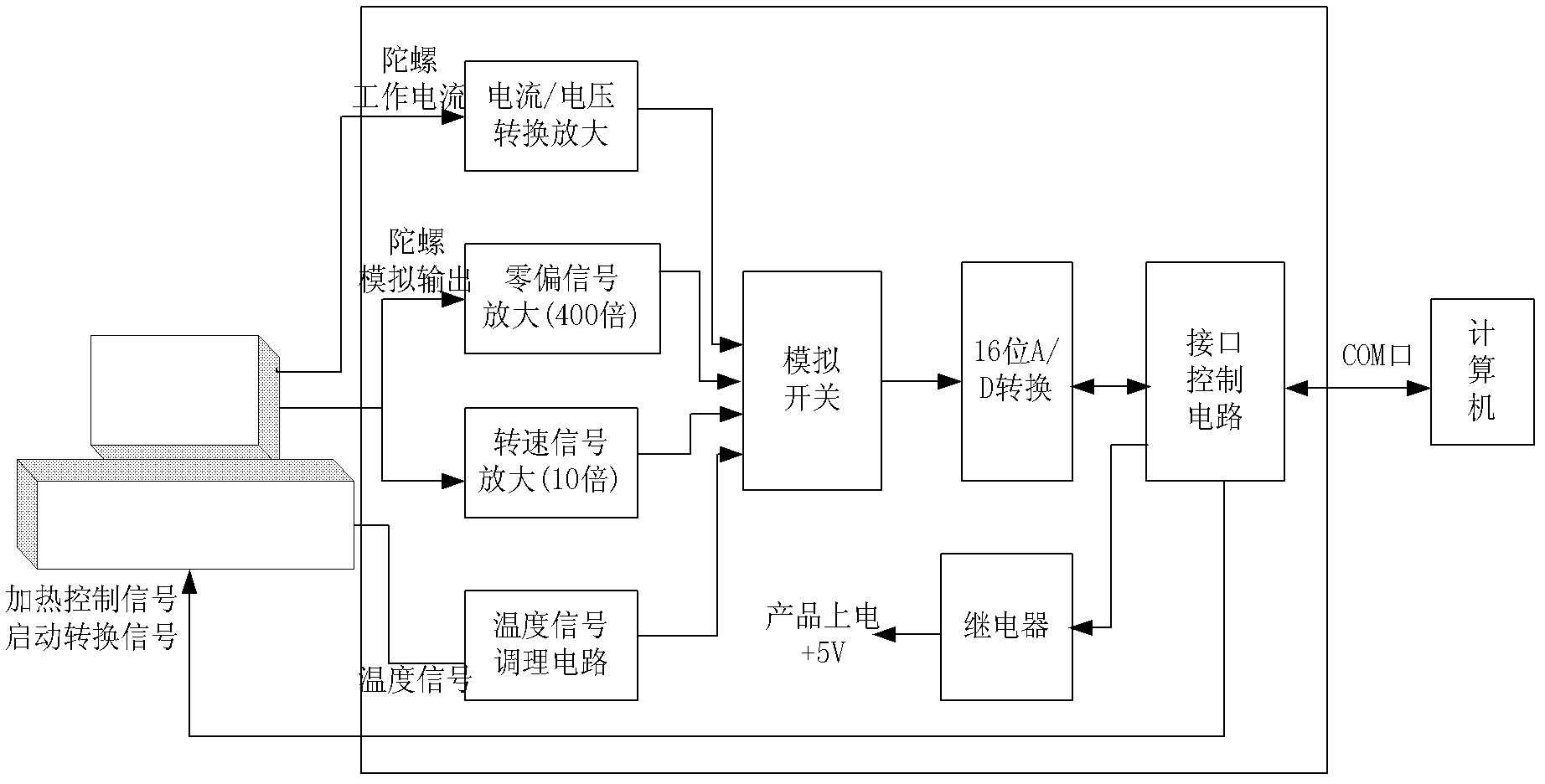

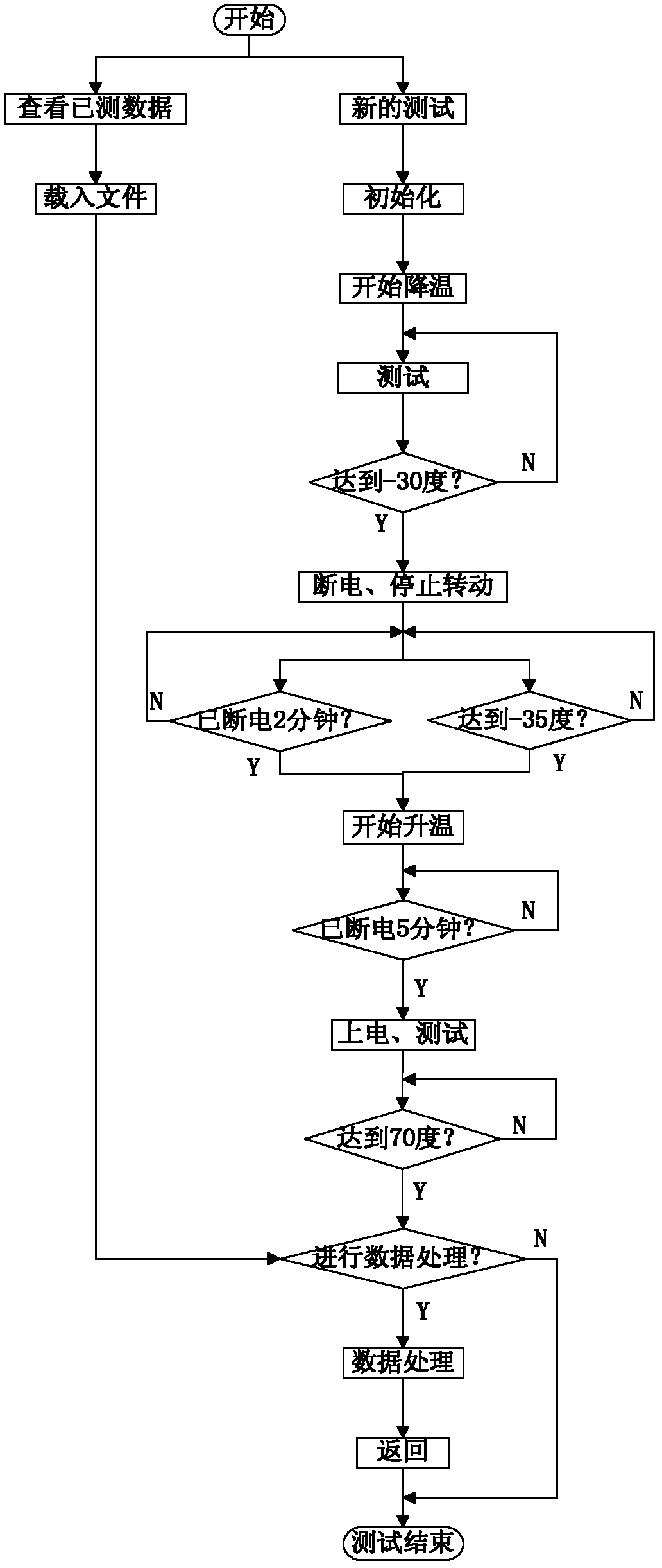

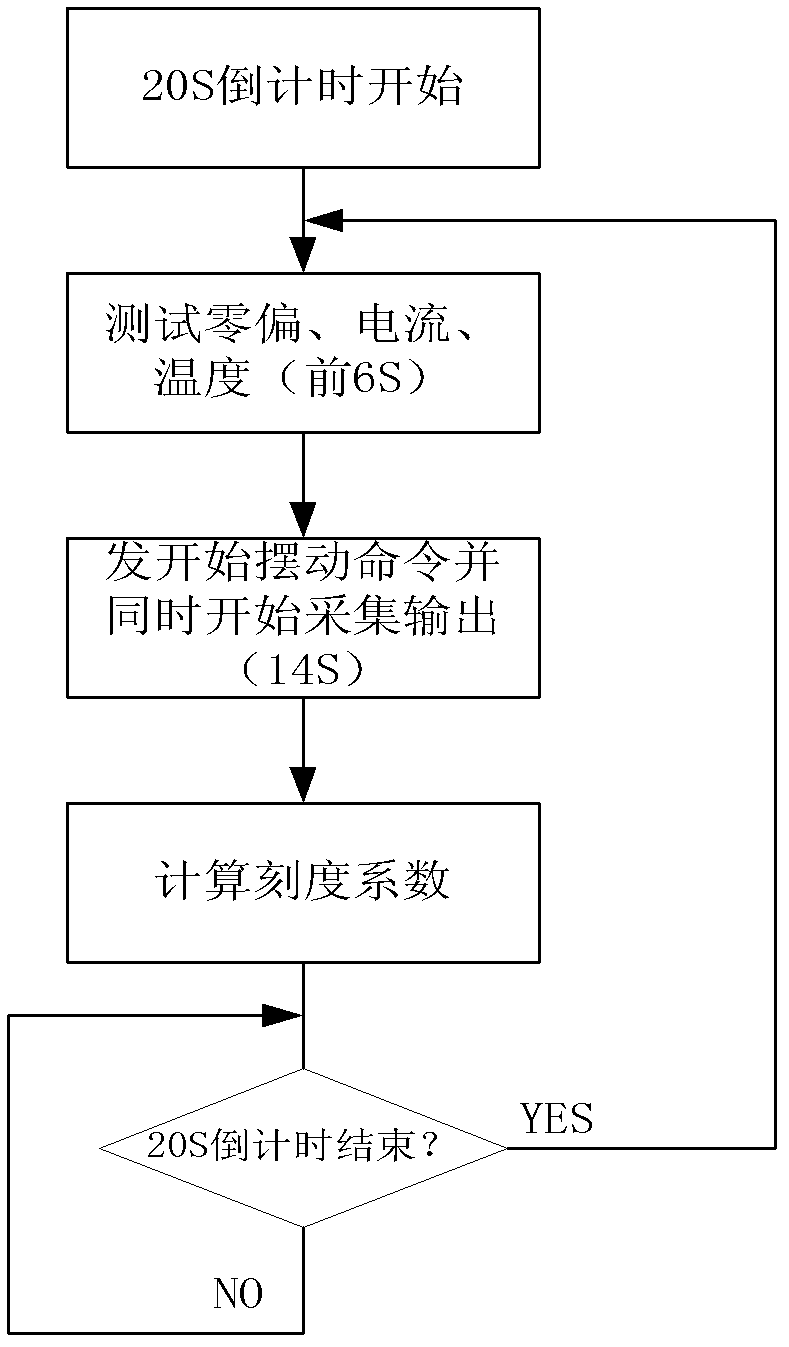

[0031] refer to figure 1 , The test system of the present invention includes three parts: an incubator turntable, a signal processing unit and a computer. The thermostat turntable is composed of a temperature controller and a turntable. The turntable is fixed on the temperature controller to provide a certain angle of rotation for the fiber optic gyroscope. The output voltage of the fiber optic gyroscope is proportional to the rotation speed of the turntable. Therefore, the collected The voltage of the fiber optic gyro corresponds to the speed of the speed. When the speed changes sinusoidally, the voltage obtained also changes sinusoidally. When the turntable is triggered and rotated each time, the area of the sinusoidal curve is calculated to obtain the scale of the fiber optic gyro. Coefficient, because the heat from the heating motor is transmitted to the fiber optic gyr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com