Digital module with temperature compensating function and temperature compensating method thereof

A temperature compensation, digital module technology, applied in the field of digital modules, can solve the problems of complex sensor structure, long thermal balance auxiliary time, low production efficiency, etc., to improve comprehensive accuracy and reliability, good consistency, and enhanced anti-interference ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

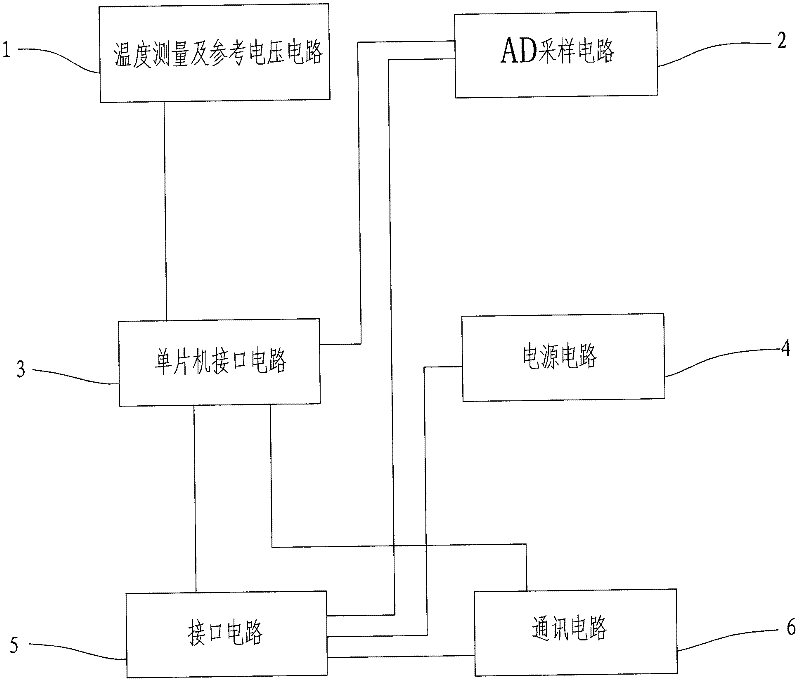

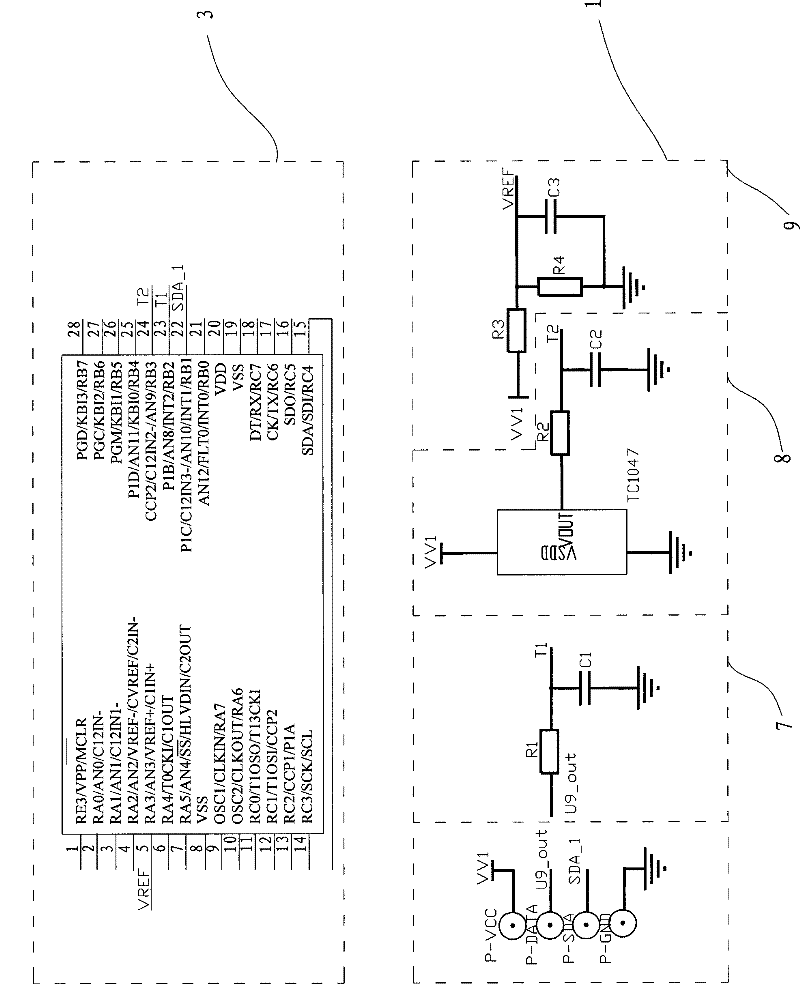

[0018] see figure 1 and figure 2 , a digital module with temperature compensation function, including temperature measurement and reference voltage circuit 1, AD sampling circuit 2, microcontroller interface circuit 3, power supply circuit 4, interface circuit 5 and communication circuit 6.

[0019] Temperature measurement and reference voltage circuit 1, external digital temperature sensor, such as precision digital temperature sensor MCP9804. The output end of the temperature measurement and reference voltage circuit 1 is connected to the single-chip microcomputer interface circuit 3, and the data collected by the digital temperature sensor is transmitted to the single-chip microcomputer interface circuit 3 for processing for temperature compensation.

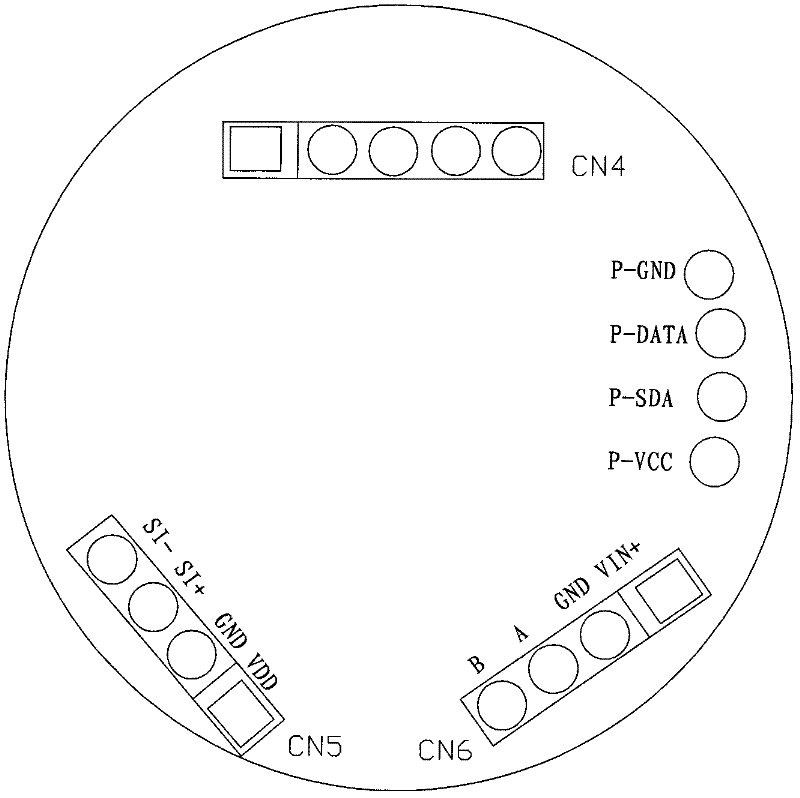

[0020] The interface circuit 5 includes three interfaces, the emulation and programmin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com