Polarization testing probe and testing method for cathodic protection of underground steel pipelines

A cathodic protection and pipeline technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problem of limited service life of test probes, and achieve the effect of feasible processing and manufacturing process plan, easy mass production, and easy quality control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

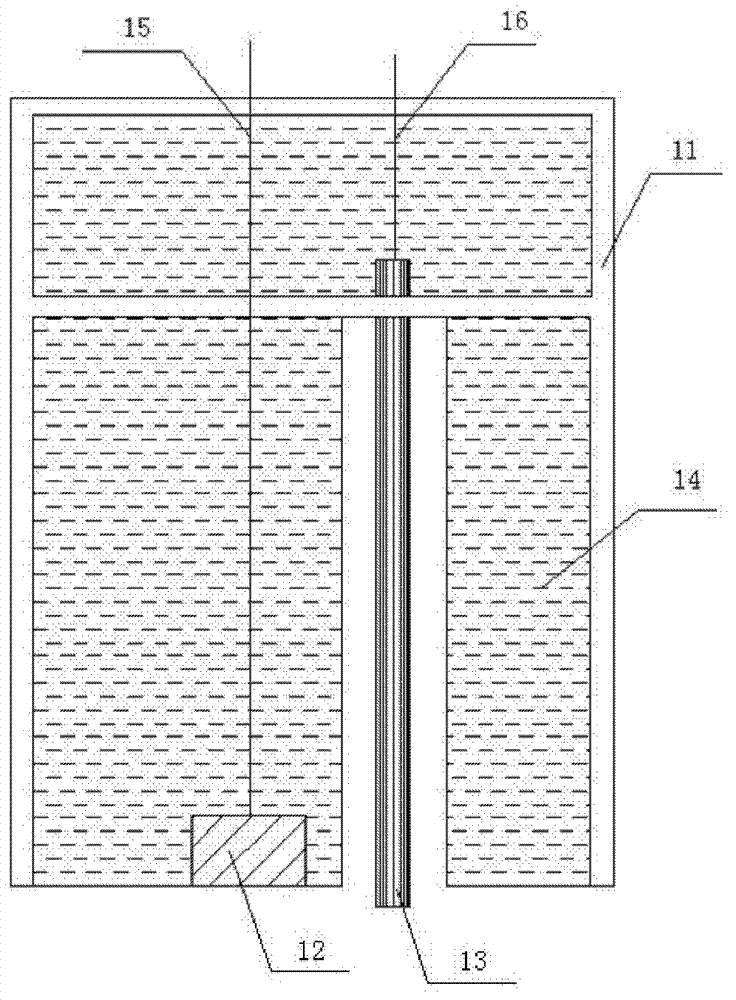

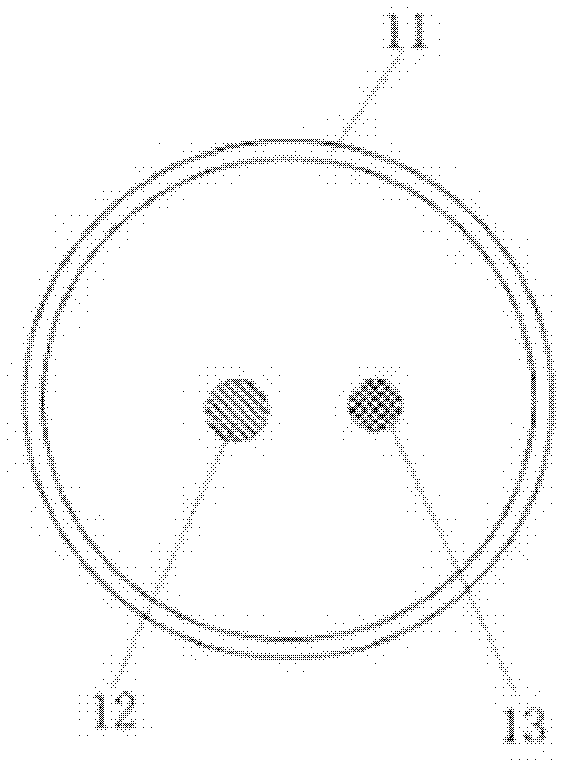

[0027] (1) The cylindrical insulating shell is manufactured by UPVC pipe and plate. The total size of the shell is Ф120×240mm. The size is Ф120×30mm;

[0028] (2) A cylindrical sample of Ф11.3×5 mm is processed by wire cutting, and the material is the same or similar to the base material of the pipeline used by the probe; a 4cm cylindrical sample 2 The bottom surface acts as a working surface, and the cable is welded on the other bottom surface, and the connection point is insulated and anti-corrosion treated; a cylindrical sample is installed on the bottom of the insulating shell by interference sealing, and only one 4cm 2 The metal working surface, and the other surfaces are sealed; the two bundles of cables connected to the two samples pass through the lower cavity, and are mechanically connected to the two cores of the multi-core cable in the upper cavity;

[0029] (3) The long-term zinc reference electrode is installed in the lower chamber of the shell by mechanical conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com