Positioning control method and system for material transportation trolley

A material transport trolley and positioning control technology, applied in two-dimensional position/channel control and other directions, can solve the problems of inability to truly determine the specific position of the trolley and inconvenience in production, improve system stability and reliability, and provide ease of use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

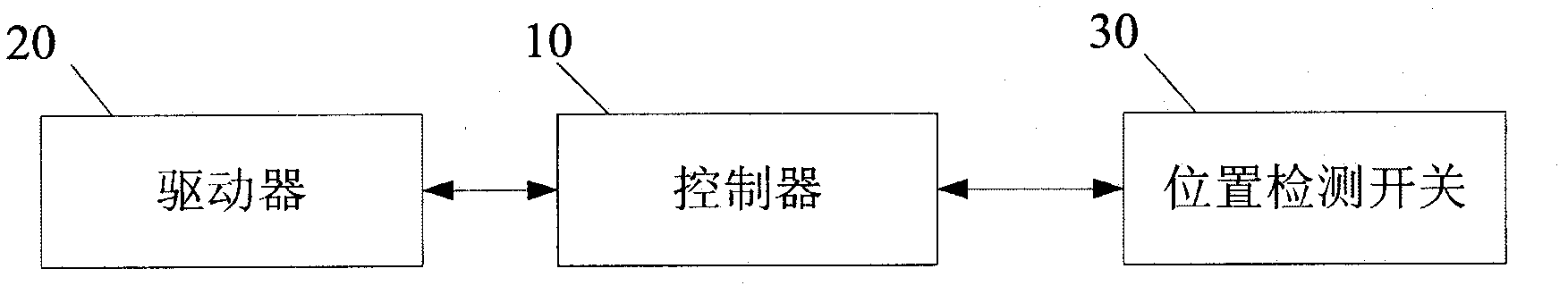

[0039] figure 1 It shows a block diagram of a positioning control system of a transport trolley according to an embodiment of the present invention. refer to figure 1 , according to the embodiment of the present invention, the positioning control system of the trolley includes a controller 10 , a driver 20 and a position detection switch 30 .

[0040] Here, the positioning control system of the transport trolley is preferably a system implemented based on a programmable logic controller (PLC).

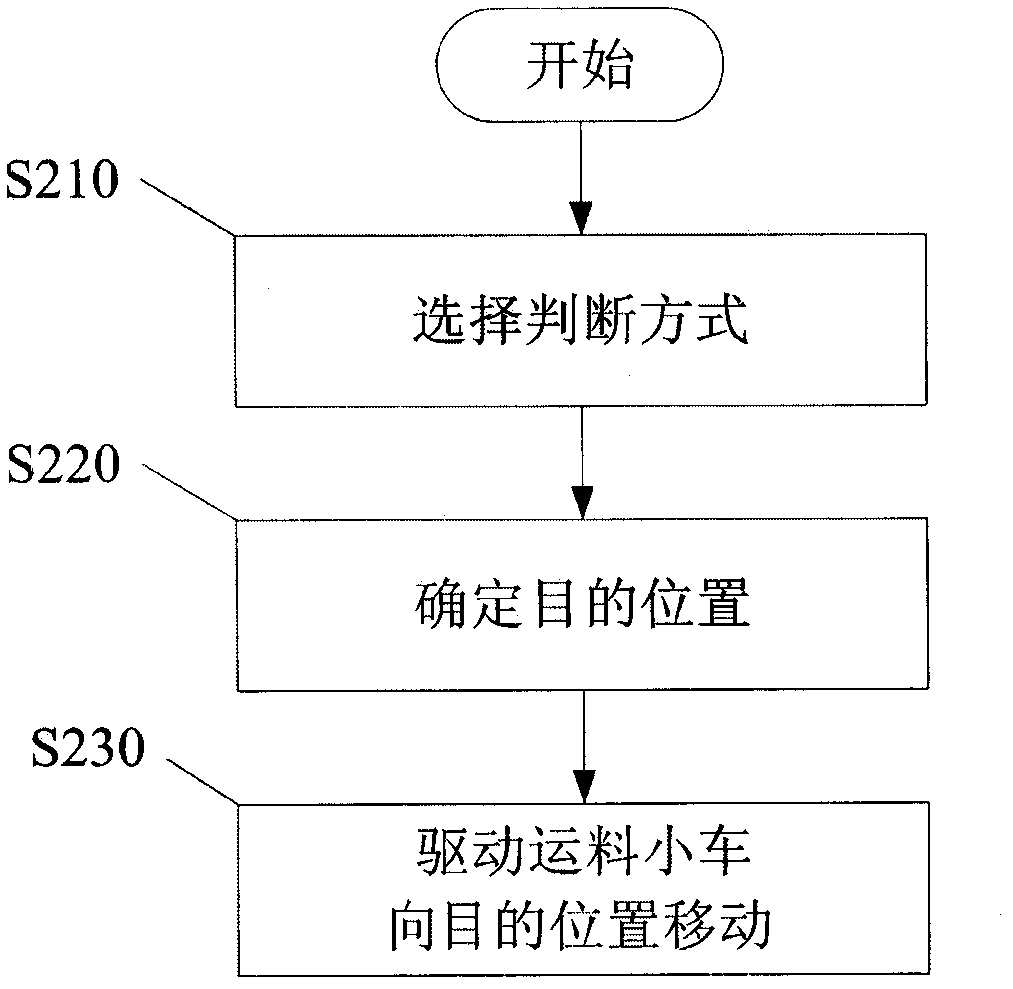

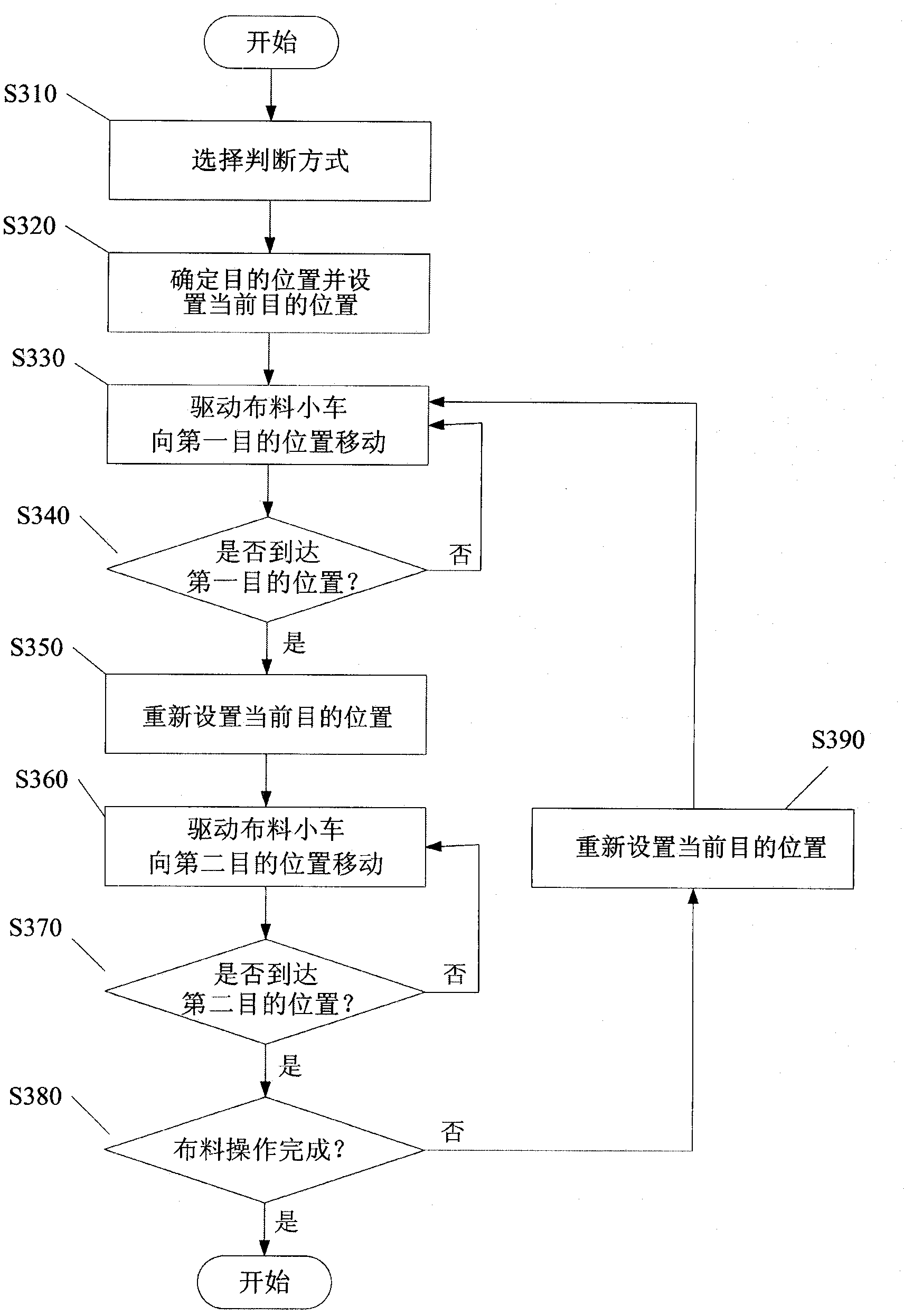

[0041] The controller 10 is used to control the operation of the positioning control system of the transport trolley. For example, the controller 10 selects a judging method for judging whether the material delivery trolley reaches the destination position based on the user's input, and determines whether the material delivery trolley reaches the destination pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com