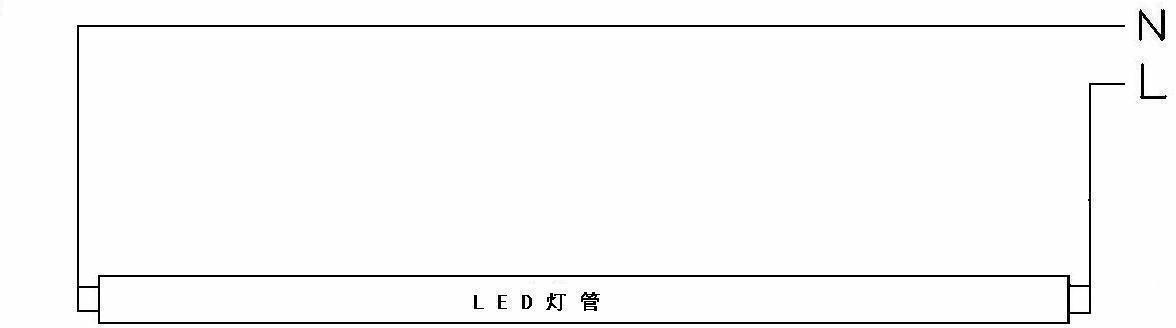

LED (light-emitting diode) tube and drive circuit thereof

A technology of LED lamp tube and driving circuit, which is applied in the direction of electric lamp circuit layout, electric light source, lighting device, etc., can solve the problems of high failure rate, many components, complicated circuit structure, etc., and achieve the effect of removing components and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] like Figure 5 and Image 6 As shown, an LED lamp drive circuit includes an input unit 1 , a rectification filter unit 2 , an LED constant current drive unit 3 , a high frequency detection unit 4 and a control unit 5 .

[0038] Preferably, the input unit 1 includes input terminals 11 , 12 , 13 and 14 , AC coupling capacitors C1 and C2 , the AC coupling capacitor C1 is connected in parallel between the input terminals 11 and 12 , and the AC coupling capacitor is connected in parallel between the input terminals 13 and 14 . Capacitor C2.

[0039] Preferably, the rectifier and filter unit 2 includes a first rectifier bridge 21 and a second rectifier bridge 22, and the first rectifier bridge 21 and the second rectifier bridge 22 are respectively composed of four fast rectifier diodes to form a two-phase rectifier bridge , the first rectifier bridge 21 is connected in parallel with the AC coupling capacitor C1 of the input unit 1 ; the second rectifier bridge 22 is connect...

Embodiment 2

[0047] like Figure 5 and Image 6 As shown, an LED lamp includes an LED light source board 6 and an LED lamp drive circuit described in Embodiment 1.

[0048] Preferably, the LED light source board 6 is two independent LED light-emitting units 61 and 62 .

[0049] Preferably, the two normally closed contacts 543 and 544 of the relay 54 of the control unit 5 of the LED light source board 6 are connected in series, and the relay 54 of the control unit 5 performs serial-parallel switching and combination.

[0050] The LED light source board 6 is composed of two independent LED light-emitting units 61 and 62 combined in series and parallel. The positive electrode of the LED light-emitting unit 62 is connected to the output positive electrode of the four-phase rectifier bridge, and the negative electrode of the LED light-emitting unit 61 is connected to the control unit. The positive electrode of the isolation diode , the negative pole of the LED lighting unit 62 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com