Transplanting mechanism of helical-tooth staggered shaft deformed ellipse gear wide and narrow row high-speed transplanter

A technology of changing ellipse and staggered axis is applied in the field of agricultural machinery, which can solve the problems of affecting the uprightness of seedlings, high processing cost of non-circular helical gears, and enlarged transmission box structure, so as to reduce invalid lateral offset and improve the quality of planting operations. , the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

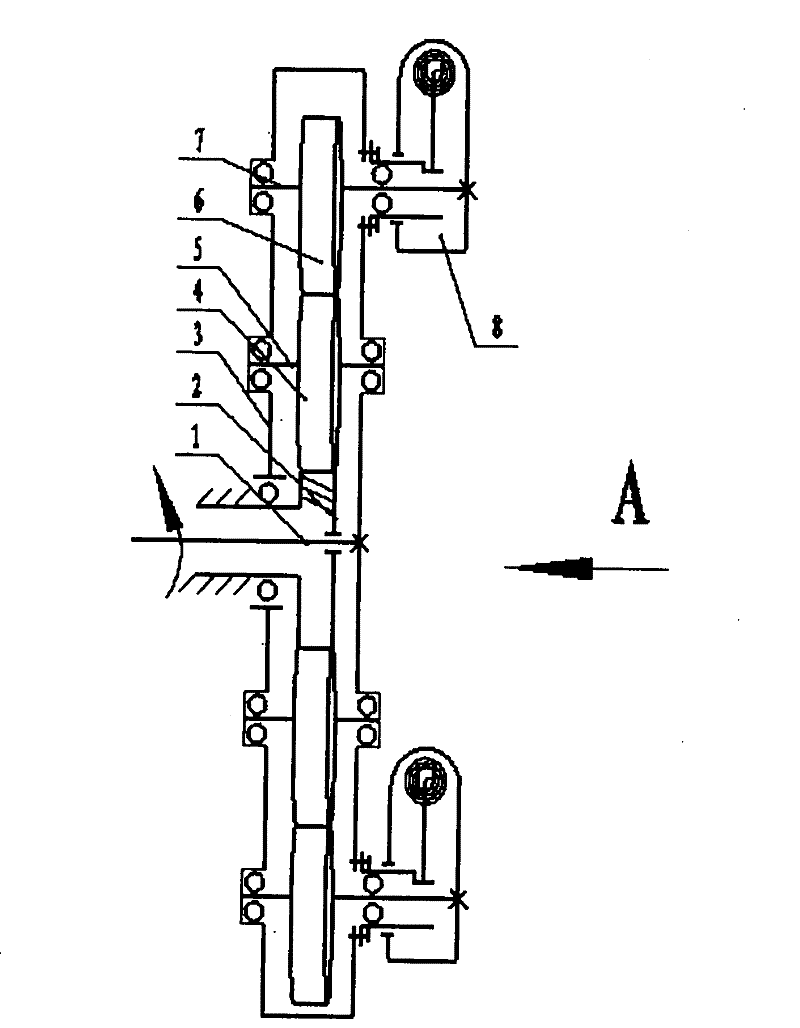

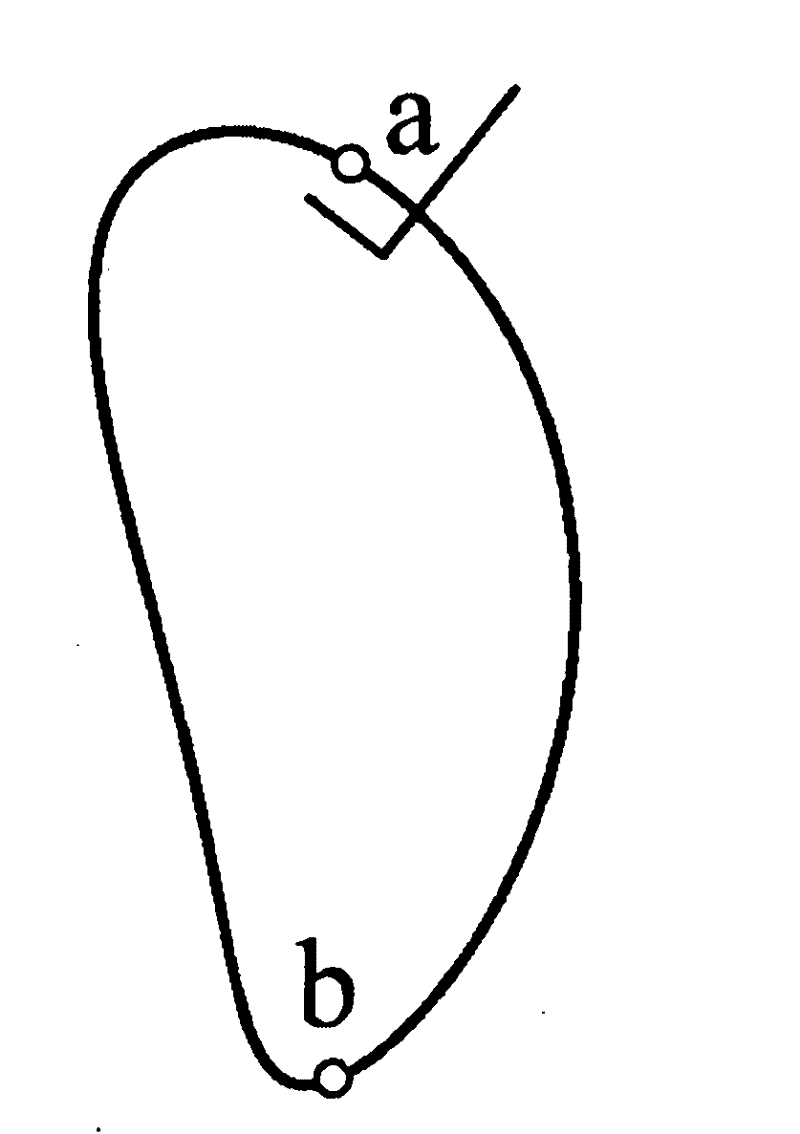

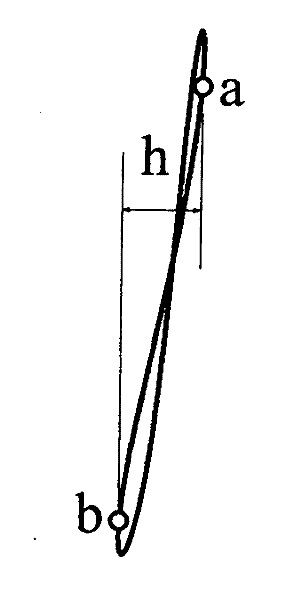

[0013] A helical-tooth cross-axis denatured elliptical gear wide-narrow row high-speed rice transplanter splitting mechanism. A sun-denatured elliptical helical gear 2 is rotatably installed on the center of the gear housing 3, and the driving central shaft 1 is rotatably inserted into the sun-denatured elliptical helical gear. In the center hole of the gear 2, one end of the driving central shaft 1 is fixedly connected to the gear housing 3; on the inner side of the gear housing 3, the intermediate axles 5 are fitted parallel to each other at the symmetrical positions on both sides of the driving central shaft 1, and the two There is a three-dimensional staggered angle between the 5-axis center line of the root intermediate wheel shaft and the 1-axis center line of the driving central shaft. 5 are equipped with an intermediate denatured elliptical s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com