A kind of rubber tube molding die and rubber tube molding method

A technology of forming molds and forming molds, which can be applied to household appliances, tubular objects, and other household appliances, etc. It can solve the problems of non-recyclable, environmental pollution, resource waste, etc., and achieve the effect of avoiding resource waste and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

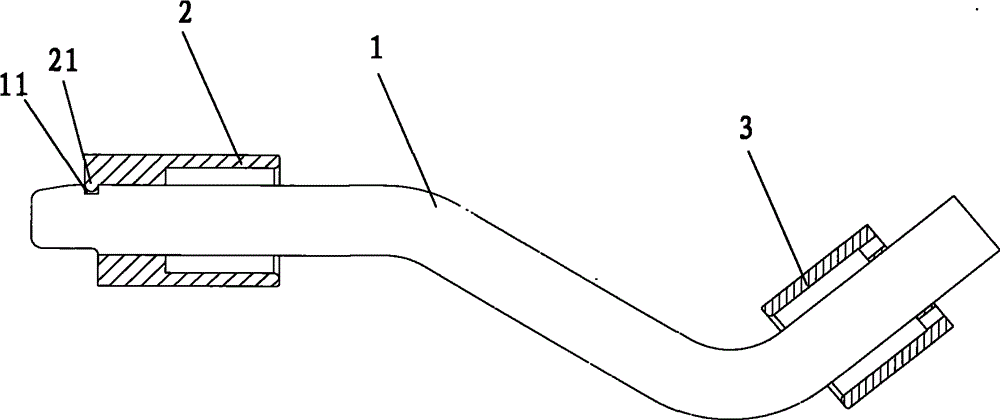

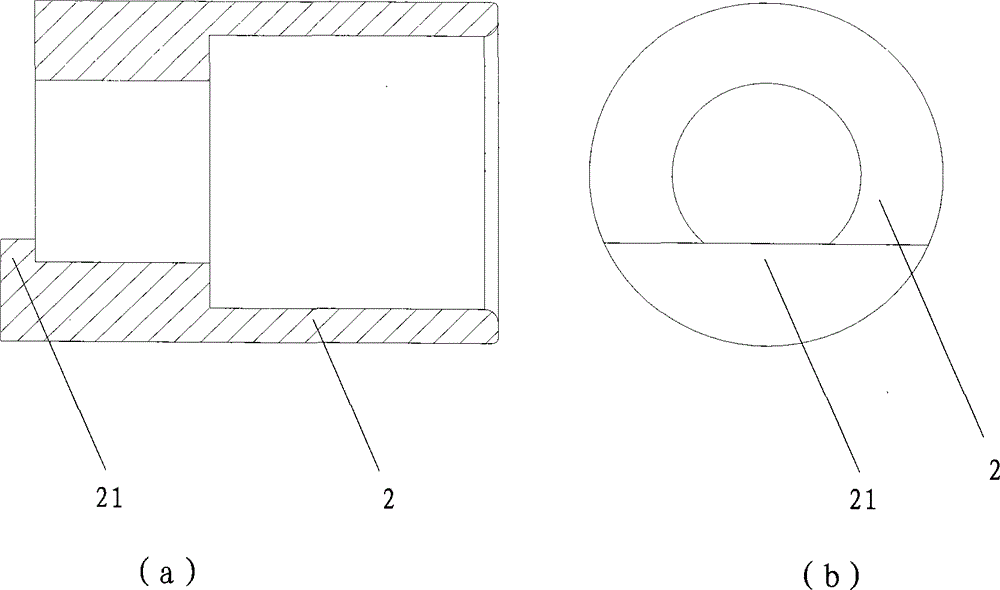

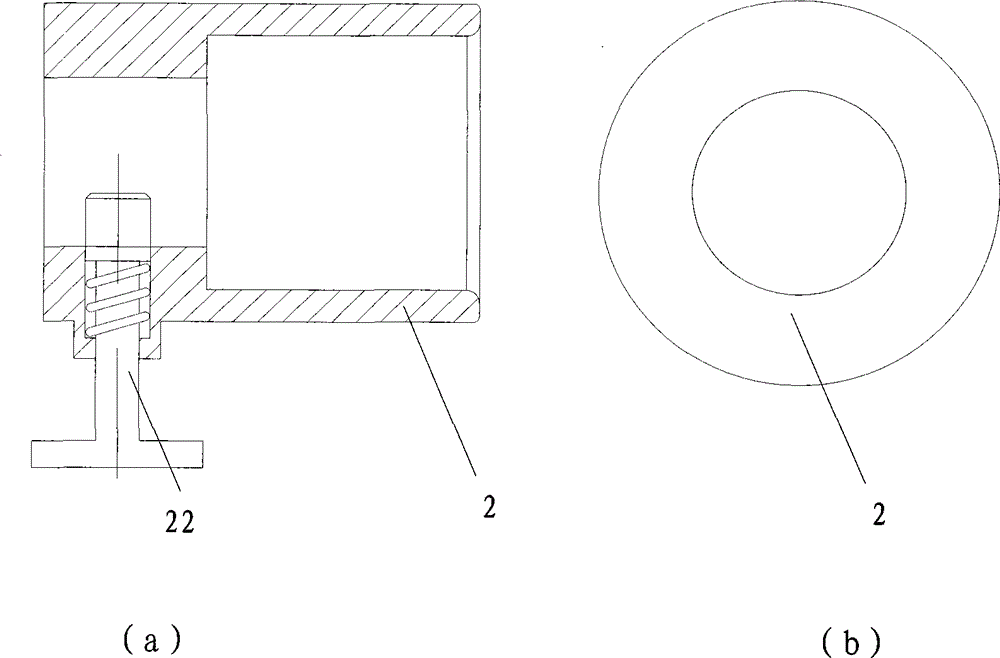

[0023] Such as figure 1 Shown is a structural schematic diagram of a rubber tube molding die proposed by the present invention. Referring to the accompanying drawings, a rubber tube molding die proposed by the present invention includes a molding core 1, a first positioning sleeve 2 and a second positioning sleeve 3, and the inner holes of the first positioning sleeve 2 and the second positioning sleeve 3 are steps hole, the first positioning sleeve 2 is detachably set on the upper end of the forming core 1, and the second positioning sleeve 3 is fixedly set on the lower end of the forming core 1 by welding or threaded connection. It should be noted that the first positioning sleeve 2 is detachably fitted on the molding core 1 to ensure the operability of the rubber tube molding mold.

[0024] The relative position between the first positioning sleeve 2 and the molding core 1 is fixed, which ensures that the relative displacement between the first positioning sleeve 2 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com