Flying saucer aircraft

A technology for an aircraft and a flying saucer, applied in the field of aircraft, can solve the problems of not running smoothly, comfortably, discharging harmful waste gas, and being unfavorable to environmental protection, and achieve the effects of being beneficial to environmental protection, low maintenance and energy consumption costs, and saving construction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

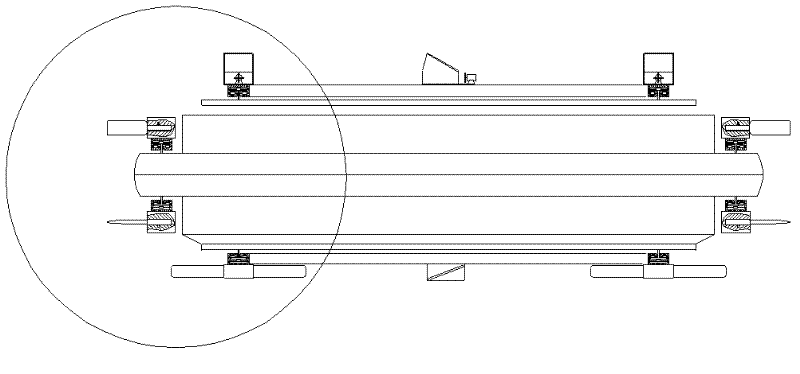

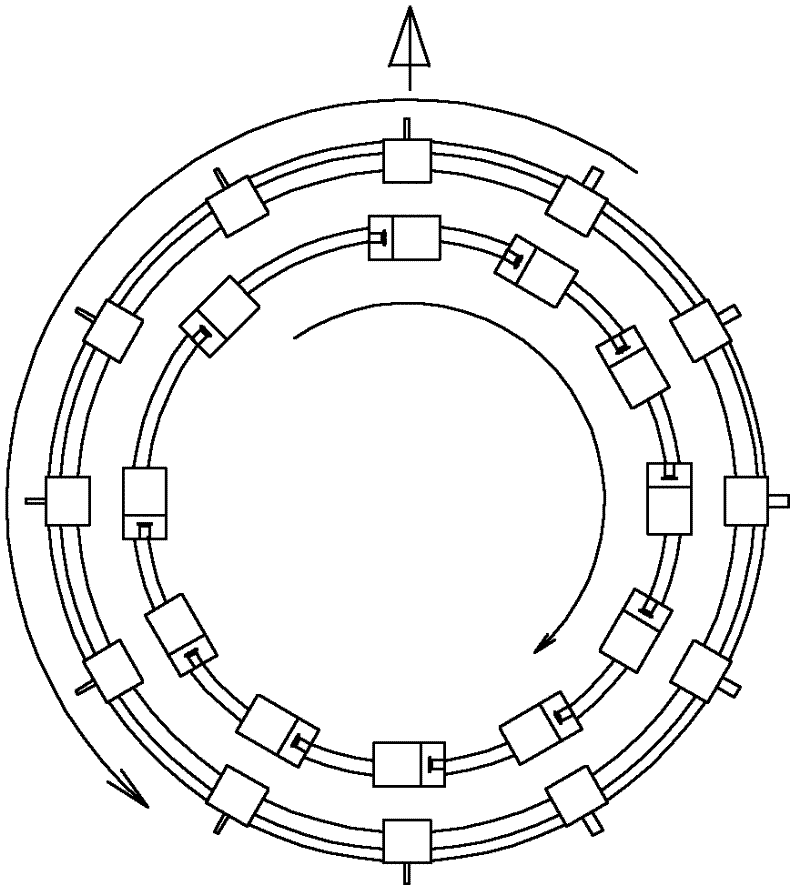

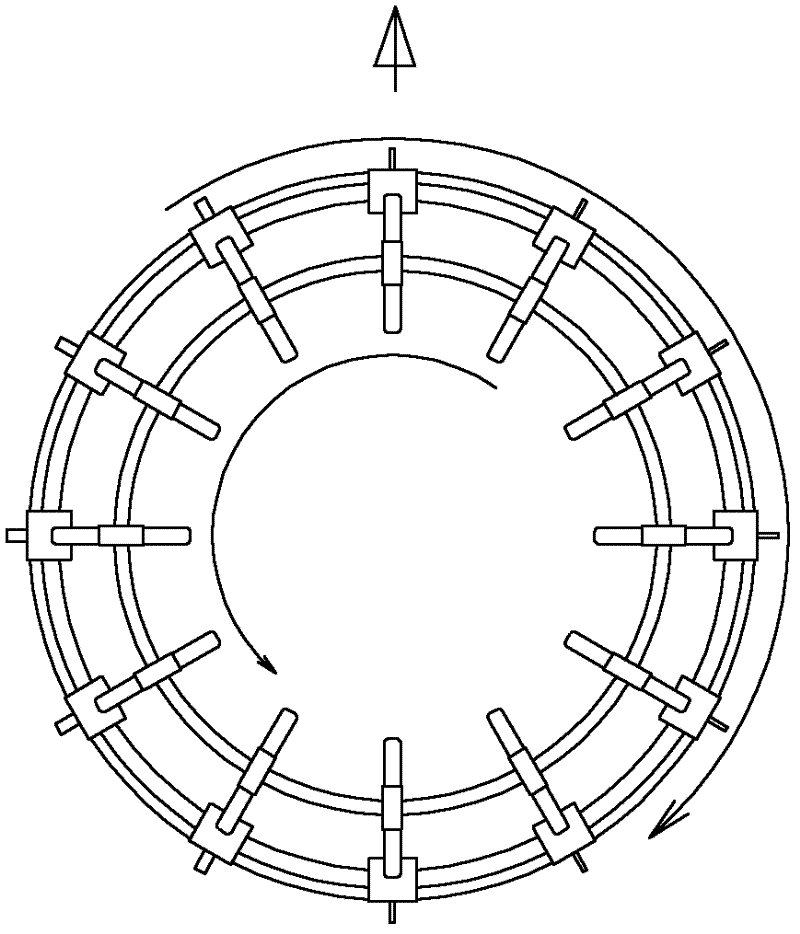

[0030] like Figure 1 to Figure 14 As shown, the first embodiment of the flying saucer aircraft of the present invention includes a disk-shaped (two interlocking dish-shaped) shell 1, and the shell 1 has a built-in power supply (not shown), and the power source is a combination of a nuclear reactor and a generator or Combustion engine combined with generator or battery.

[0031] see Figure 1 to Figure 4 There are four annular ferromagnetic guide rails 2, 3, 4, and 5 on the outer surface of the housing 1: upper inner, upper outer, lower inner and lower outer.

[0032] The upper inner annular ferromagnetic guide rail 2 is provided with a plurality of lifting force generating vehicles 6, and the structure is as follows: the vehicle body is a rectangular tube with a horizontal axis and tangent to the annular ferromagnetic guide rail, and the top panel of the rectangular tube is high in front and low in the back so as to be generated in the wind. Lifting force, the bottom of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com