Waterproof method for slab joints of blanket plate

A technology of bedding boards and bedding boards, which is applied to safety islands, buildings, etc., can solve problems such as adverse effects on project quality and construction environment, no bedding boards, and no effective waterproofing system for bedding boards, etc., to achieve low cost, easy waterproofing, Ease of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

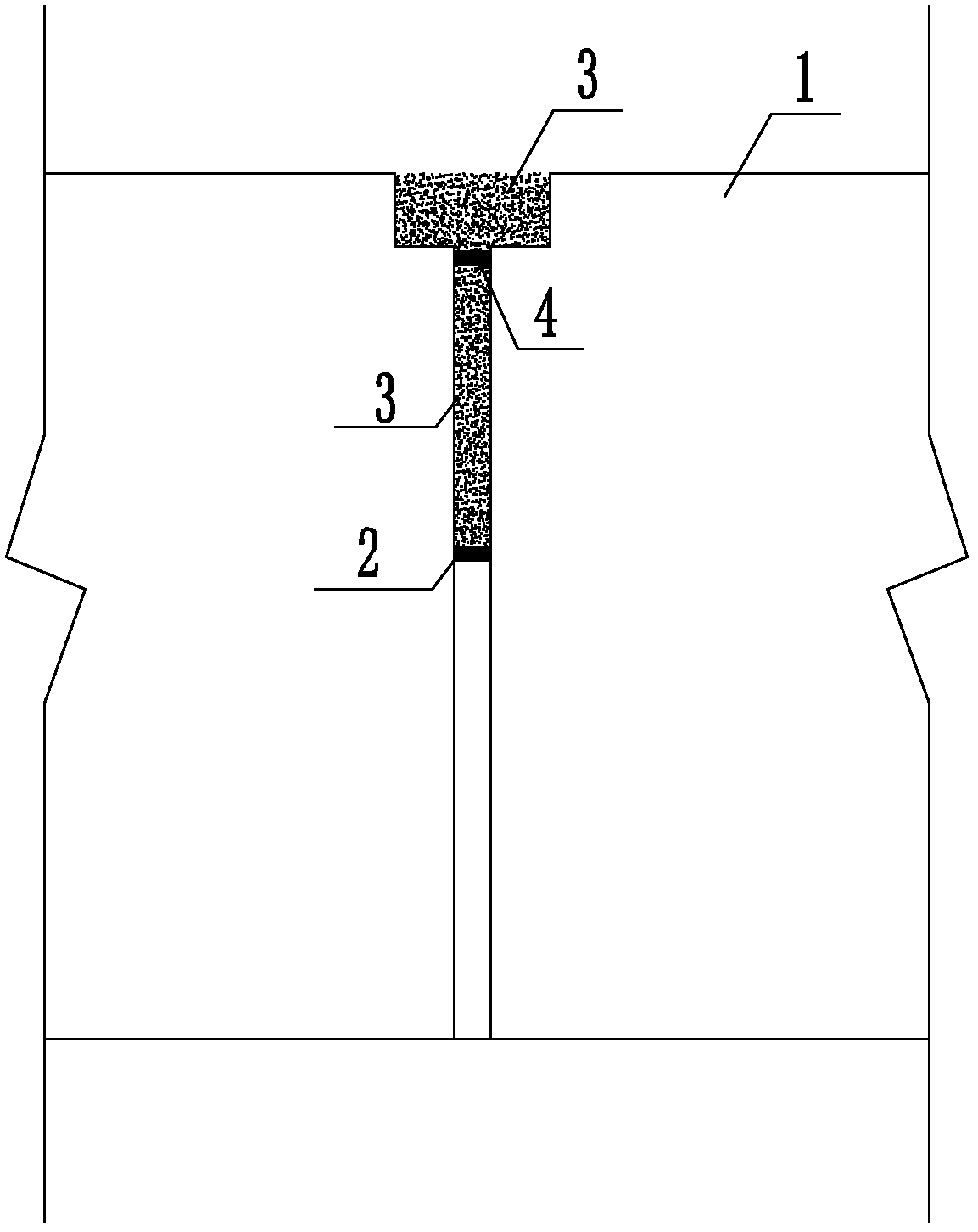

[0020] Example 1: Including the following steps:

[0021] (1) Remove the sundries between the seams of the bedding board 1, brush with a steel wire brush to remove the rust, and then wipe it with cotton silk;

[0022] (2) Pack the first layer of PE foam rod 2, the gap between the cover plate 1 is greater than or equal to 5mm, the diameter of the first layer of PE foam rod 2 is 10mm, and it is placed at the depth of 80mm between the plates;

[0023] (3) Use single-component polyurethane waterproof coating 3 to continuously infuse the board seam, with a depth of 50mm, and to continuously infuse across the cross-connecting position of the cover plate 1 during the infusion;

[0024] (4) Pack the second layer of PE foam rod 4, the diameter of the second layer of PE foam rod 4 is 10mm, and the second layer of PE foam rod 4 is 10mm from the top of the board;

[0025] (5) Pour the remaining board seams to the top of the board with one-component polyurethane waterproof coating 3, and pour in two...

Embodiment 2

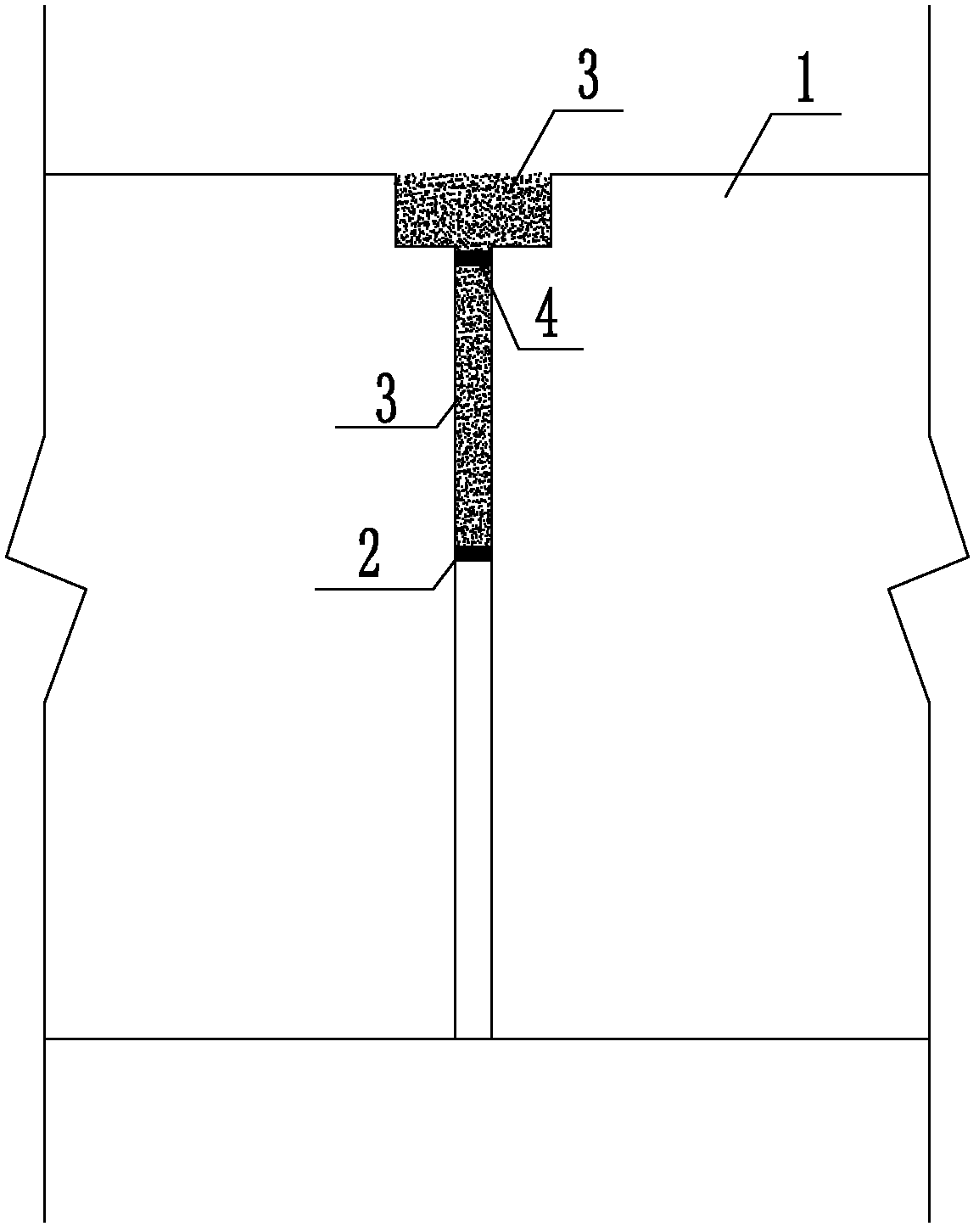

[0028] Embodiment 2: Including the following steps:

[0029] (1) Remove the sundries between the seams of the bedding board 1, brush with a steel wire brush to remove the rust, and then wipe it with cotton silk;

[0030] (2) Pack the first layer of PE foam rod 2, the gap between the cover plate 1 is less than 5mm, the diameter of the first layer of PE foam rod 2 is 5mm, and it is placed at a depth of 80mm between the plates;

[0031] (3) Use single-component polyurethane waterproof coating 3 to continuously infuse the board seam, with a depth of 60mm, and continuously pour across the cross-connecting position of the cover plate 1 during the infusion;

[0032] (4) Pack the second layer of PE foamed rod 4, the diameter of the second layer of PE foamed rod 4 is 5mm, and the second layer of PE foamed rod 4 is 10mm from the top of the board;

[0033] (5) Pour the remaining board seams to the top of the board with one-component polyurethane waterproof coating 3, and pour in two times. The fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com