Wind load resistant connector for unitized curtain walls

A unit curtain wall, wind pressure resistance technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of waste of connector size, strict requirements for hanging positioning, etc., to achieve convenient installation and operation, save material costs and installation costs, and adjust Simple and easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

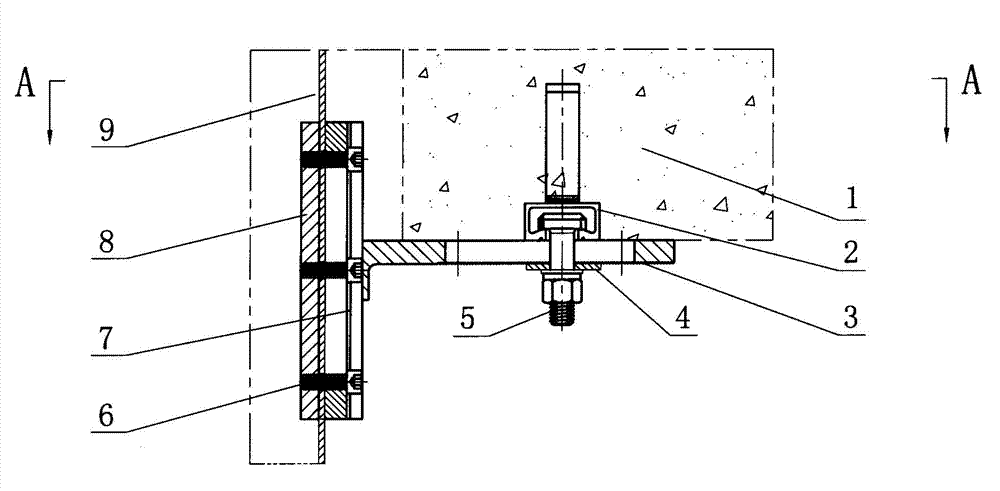

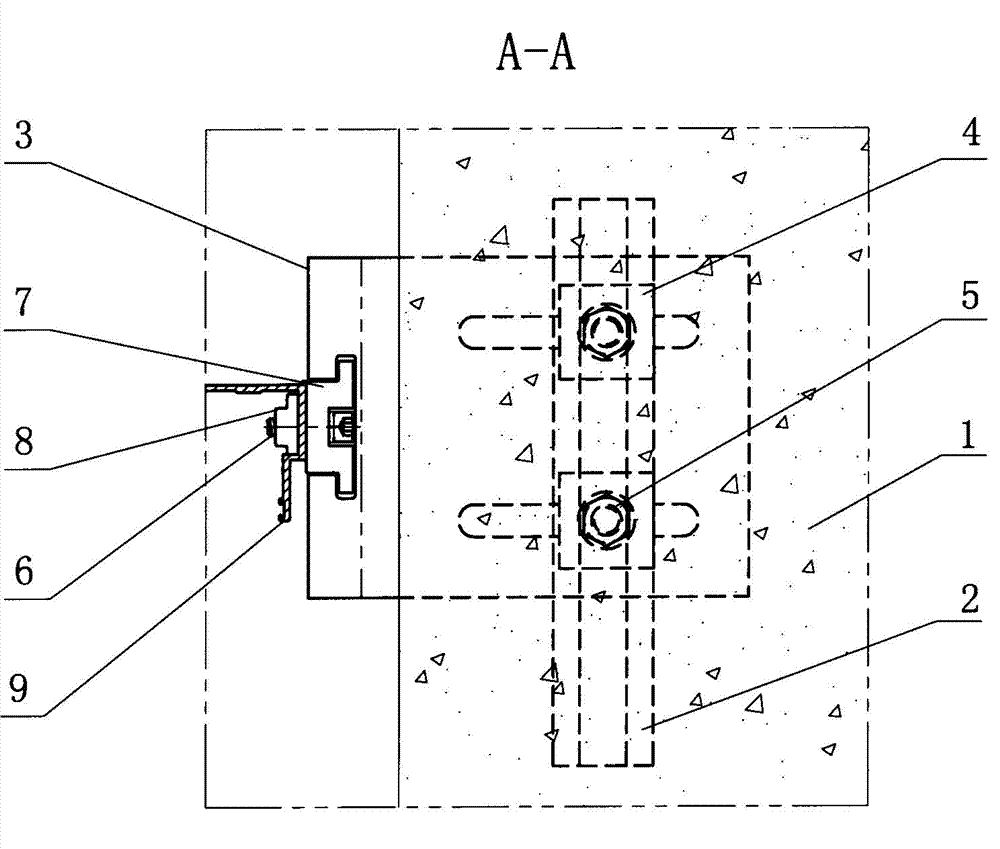

[0011] according to Figure 1~2 The specific structure of the present invention will be described in detail. The unit curtain wall anti-wind pressure connector includes a pendant fixed on the curtain wall unit plate and a main stress member 3 fixed on the groove embedded part 2 of the civil construction beam 1 and the like. Among them, the pendant is arranged in a "several shape" to ensure uniform force-bearing symmetrical wings and components embedded in the grooves of the connecting bolt heads. The wall thickness of the several-shaped component 7 can be adjusted according to design requirements, and is fixed on the side of the main mullion 9 in the plug-in mullion on the curtain wall unit plate through the tapping backing plate 8 and the connecting bolt 6 . The main force-bearing member 3 adopts an L-shaped profile whose long and short sides are arranged perpendicular to each other. Along its long side, a waist-shaped hole that can completely absorb civil engineering devia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com