Automatic falling preventing device for integral lifting scaffold

An overall lifting and scaffolding technology, which is applied to the scaffolding of building structure support, building structure support, building structure support, etc., can solve the problems of poor reliability, falling, complex overall structure and transmission form, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

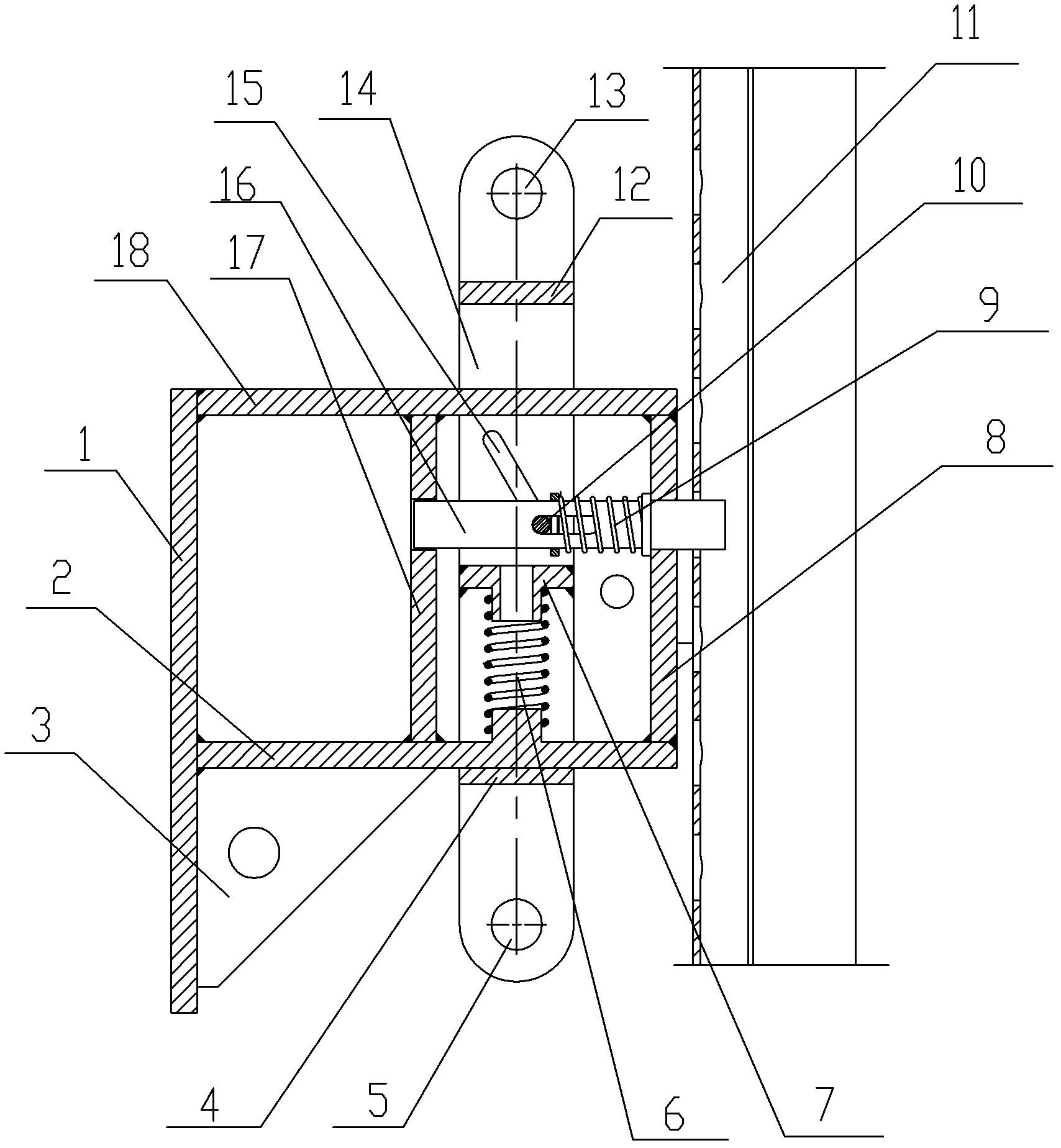

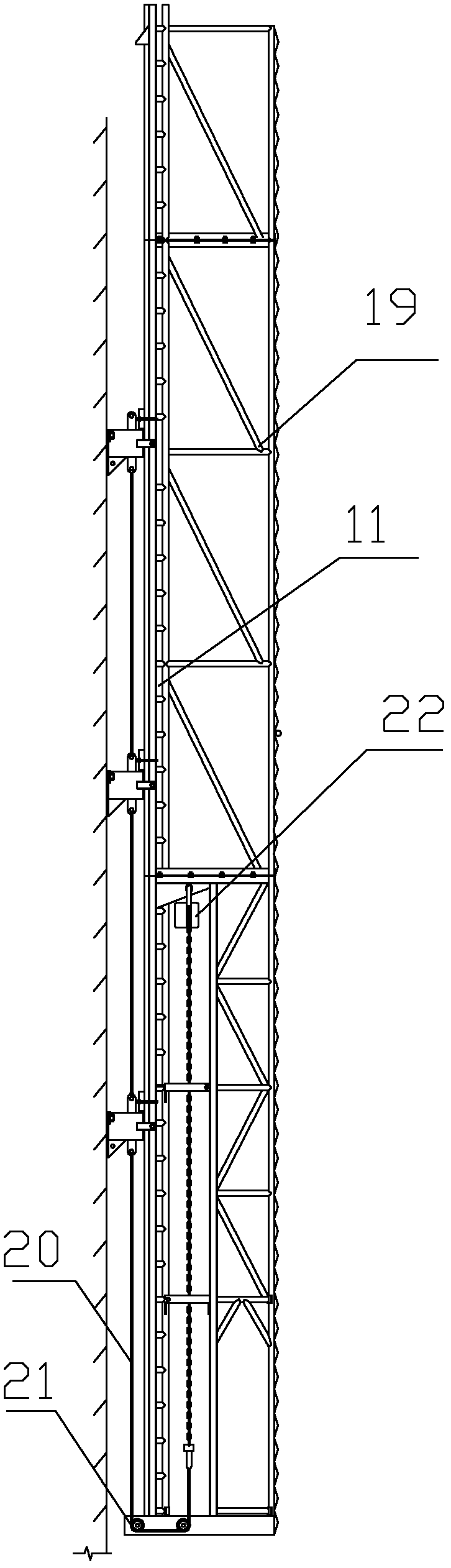

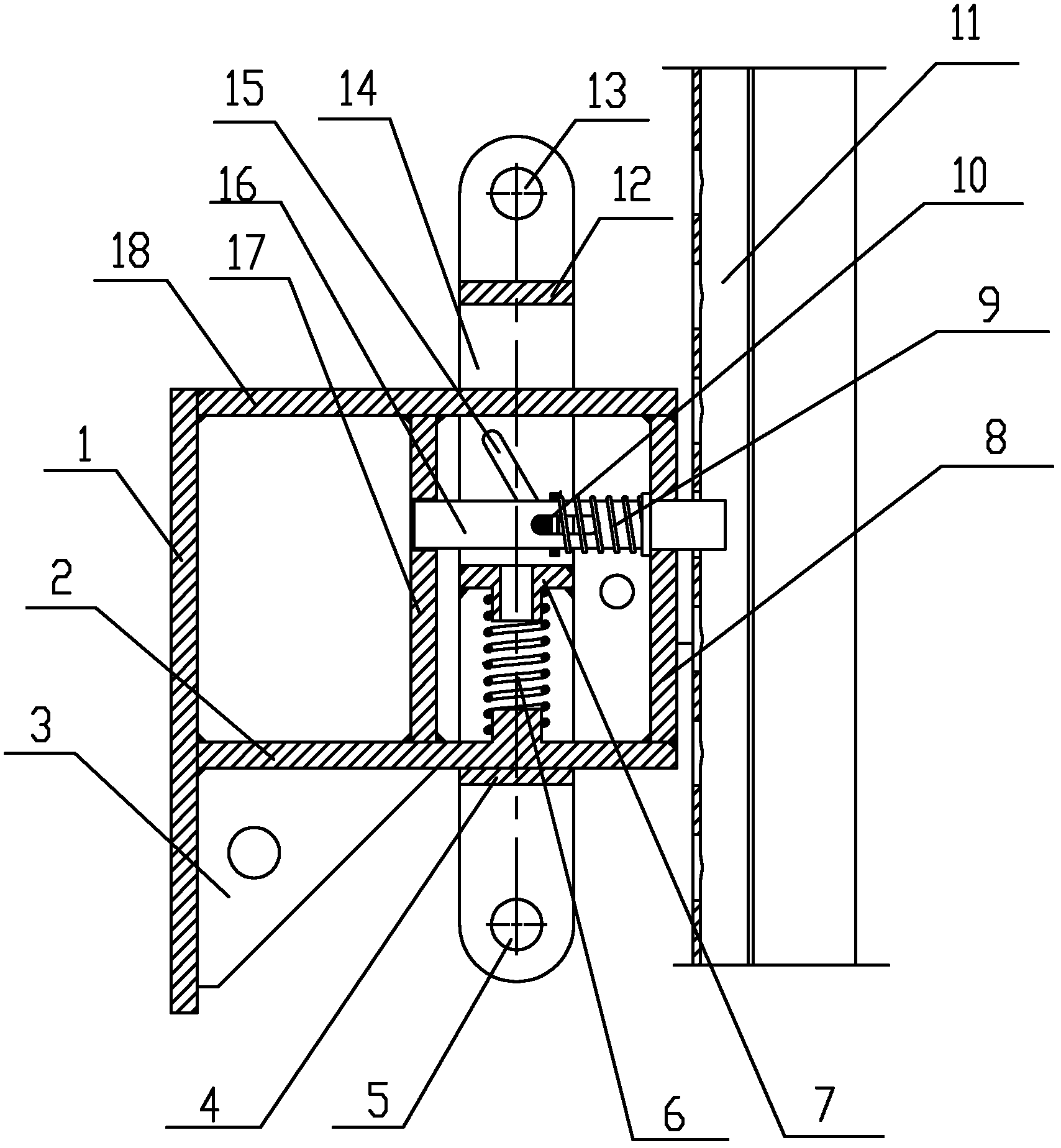

[0017] Reference figure 1 , Is an automatic fall prevention device for integral lifting scaffolding of the present invention, wherein the wall-attached vertical plate 1 is fixed to the building wall, and the upper cover plate 18 and the lower cover plate 2 are horizontally parallel to the wall-attached vertical plate 1 , The corners of the wall-attached vertical plate 1 and the lower cover plate 2 are provided with ribs 3, the hanging plate 14 slides up and down through the upper cover plate 18 and the lower cover plate 2, and the upper limit block 12 and the lower limit block 4 are set on the hanging plate 14. , The upper limit block 12 and the lower limit block 14 are located outside the upper cover plate 18 and the lower cover plate 2 respectively, and the hanging plate 14 can produce a certain displacement relative to the upper cover plate 18 and the lower cover plate 2. An oblique strip hole 15 is provided in the upper part of the hanging plate 14, a spring seat 7 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com