Zero reading level measurement method and accurate adjustment structure for height of leveling instrument

A technology of elevation measurement and level instrument, which is applied in the direction of height/level measurement, measuring devices, instruments, etc., can solve the problems of increasing the difficulty of measurement and the great safety risk of surveyors, so as to avoid difficulty and unsafety, improve work efficiency, and accurately The effect of adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

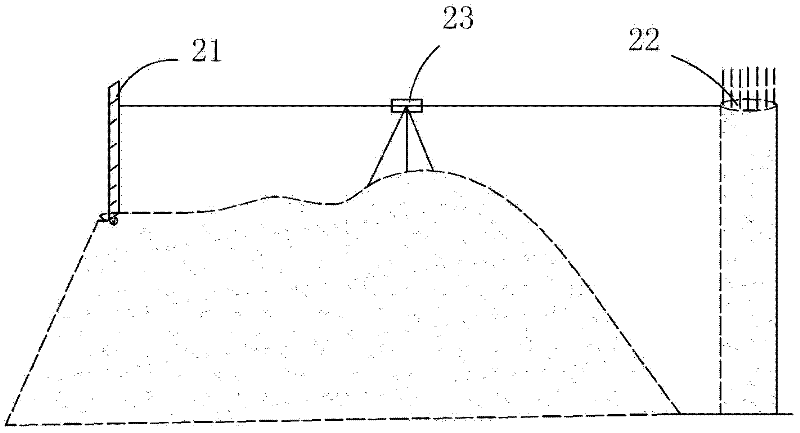

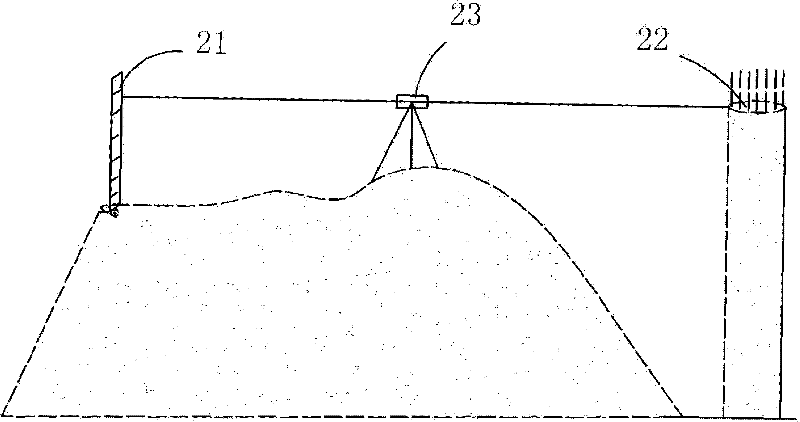

[0018] see figure 1 , the zero-reading elevation measurement method in the present embodiment is to carry out as follows:

[0019] 1. Select a location equivalent to the top surface elevation of the measured component 22 to erect the level gauge 23 and the backsight leveling rod 21 respectively; Within the measurable range; the line-of-sight length difference between the level 23 and the measured component 22 and the backsight leveling rod 21 is not more than 1m;

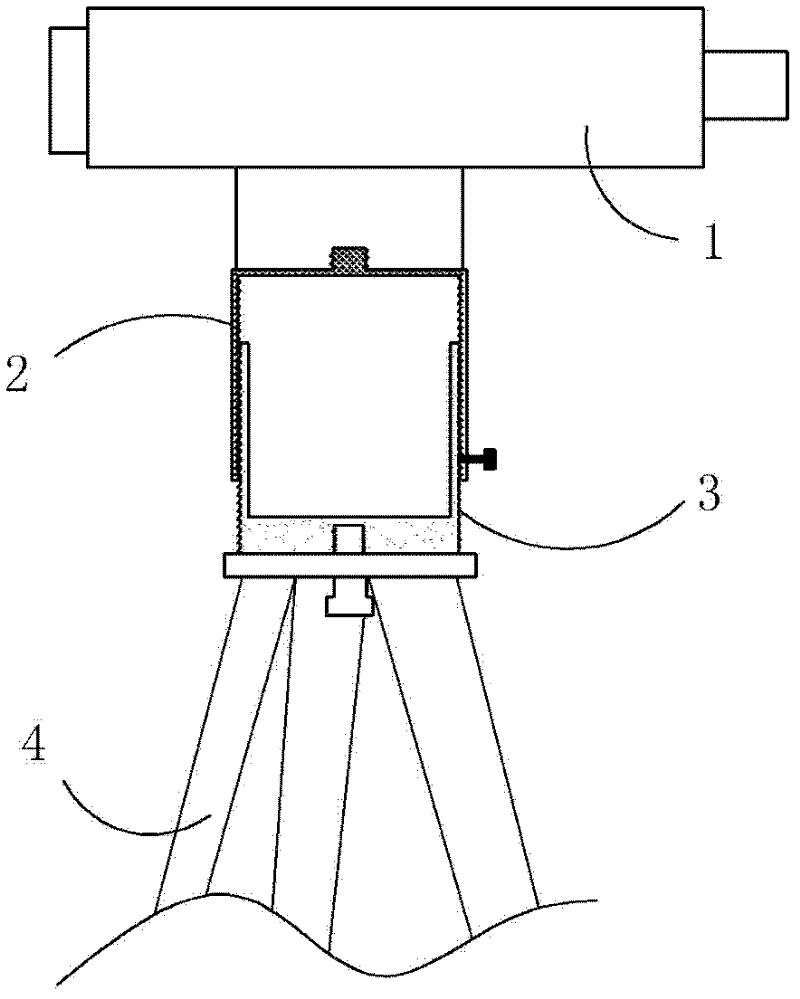

[0020] 2. Accurately adjust the height of the level 23 so that the top surface of the measured component 22 is level with the height of the level marking wire in the level 23;

[0021] 3. Keep the adjusted height of the leveling instrument 23, turn the leveling instrument 23 towards the backsight leveling rod 21, and define the corresponding height position of the leveling mark wire in the leveling device 23 on the backsighting leveling rod 21 at this time as the backsight point A;

[0022] 4. Use the known leveli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com