Transformer

A transformer and metal plate technology, applied in the field of transformers, can solve the problems of complex manufacturing process of high-power transformers, rising copper wire prices, etc., and achieve the effects of convenient external lead wire connection, increased surface area, and reduced transformer thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is described in detail below in conjunction with the accompanying drawings:

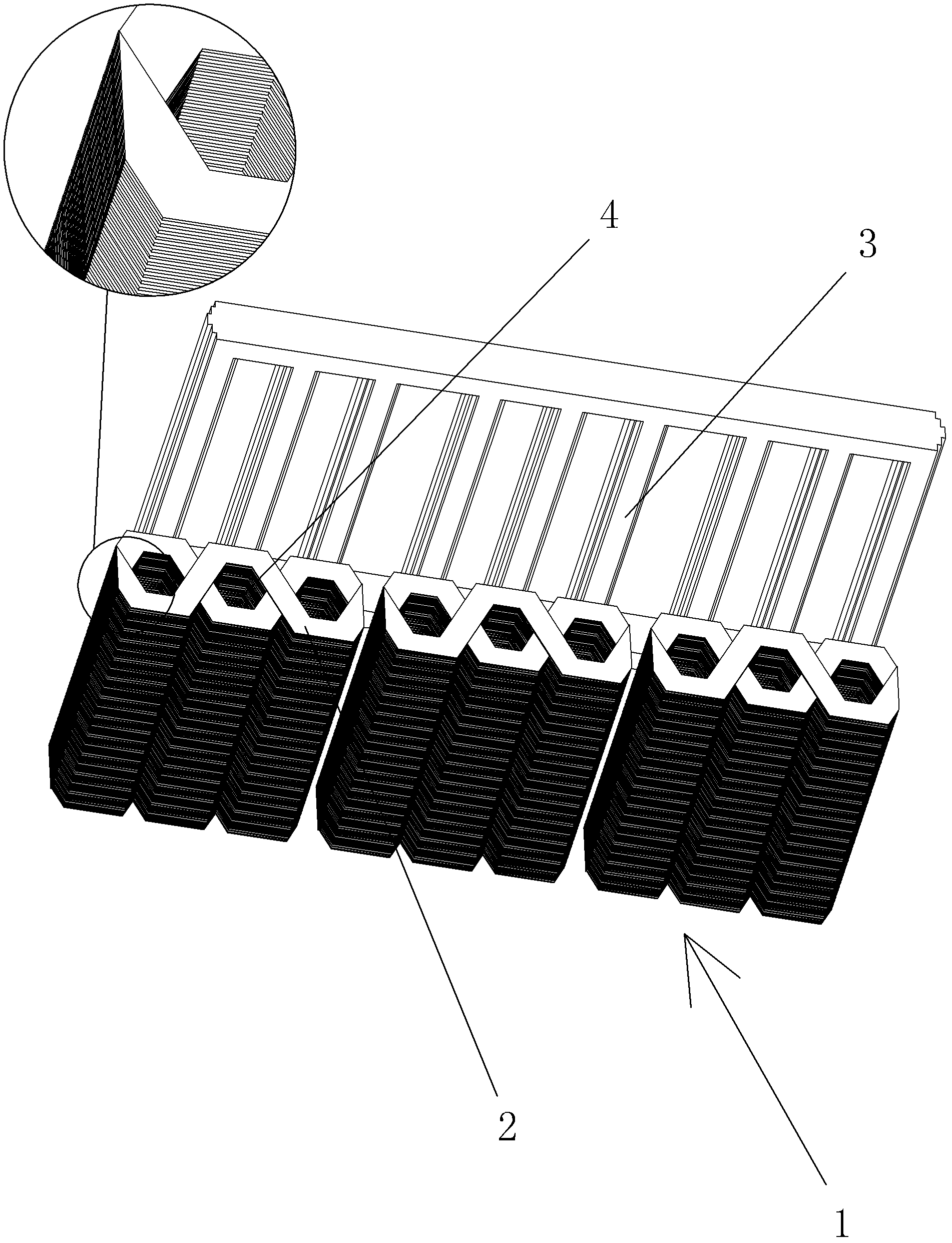

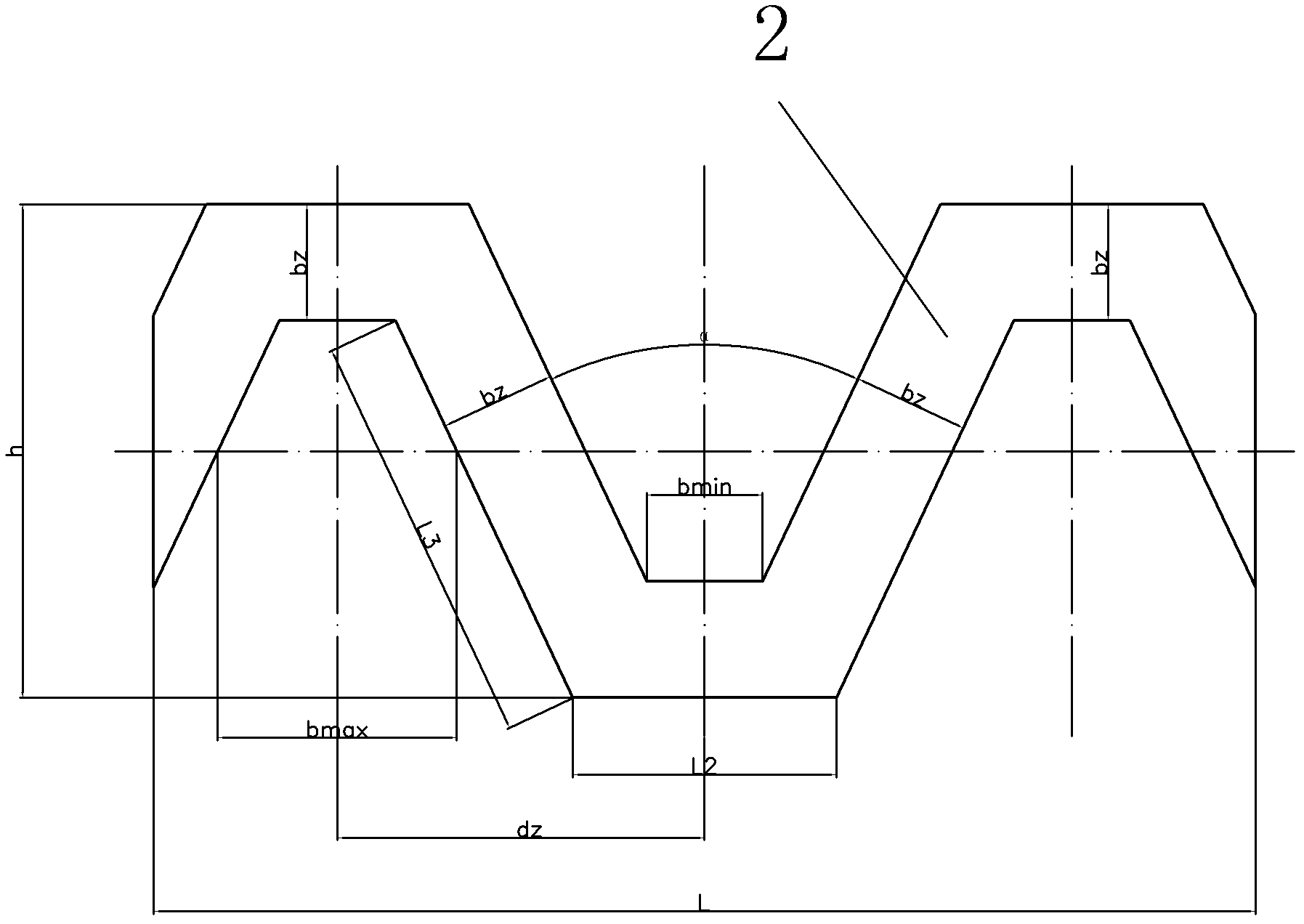

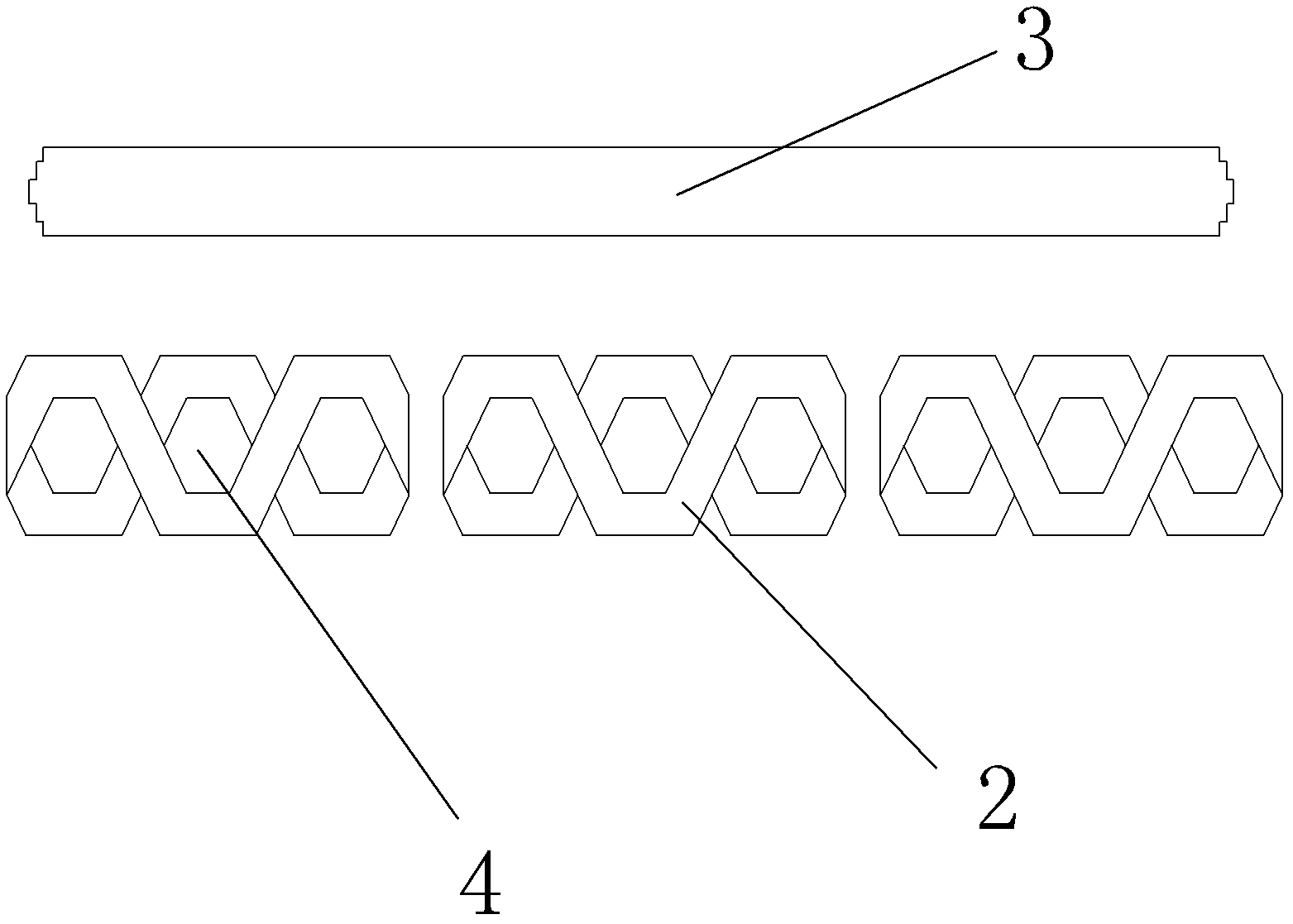

[0032] As shown in the figure, the transformer includes a zigzag winding 1 made of metal. The zigzag winding 1 is formed by connecting a plurality of zigzag metal plates 2 head and tail in turn and superimposed layer by layer, that is, a plurality of metal plates. They are stacked in sequence, and then the head and tail ends of the adjacent metal plates are connected, so that one end of the uppermost metal plate and one end of the lowermost metal plate can be energized, which is equivalent to the "coil" of the transformer. The surface of the meander winding 1 has through holes 4 formed by stacking metal plates 2 , and a magnetic core 3 is inserted into the through holes 4 . The shape of the through hole 4 is the same as that of the magnetic core 3 . Due to the use of metal plates as "coils", the power is greatly increased.

[0033] As a preferred mode of this embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com