Multistage automatic heating system and method for vehicle

An automatic and vehicle technology, applied in the field of multi-level automatic heating system of vehicles, can solve the problems of unintelligent, wrong heating, drivers forget to turn on or off the heating function, etc., and achieve reliable heating control and logical function Reasonable and reliable heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

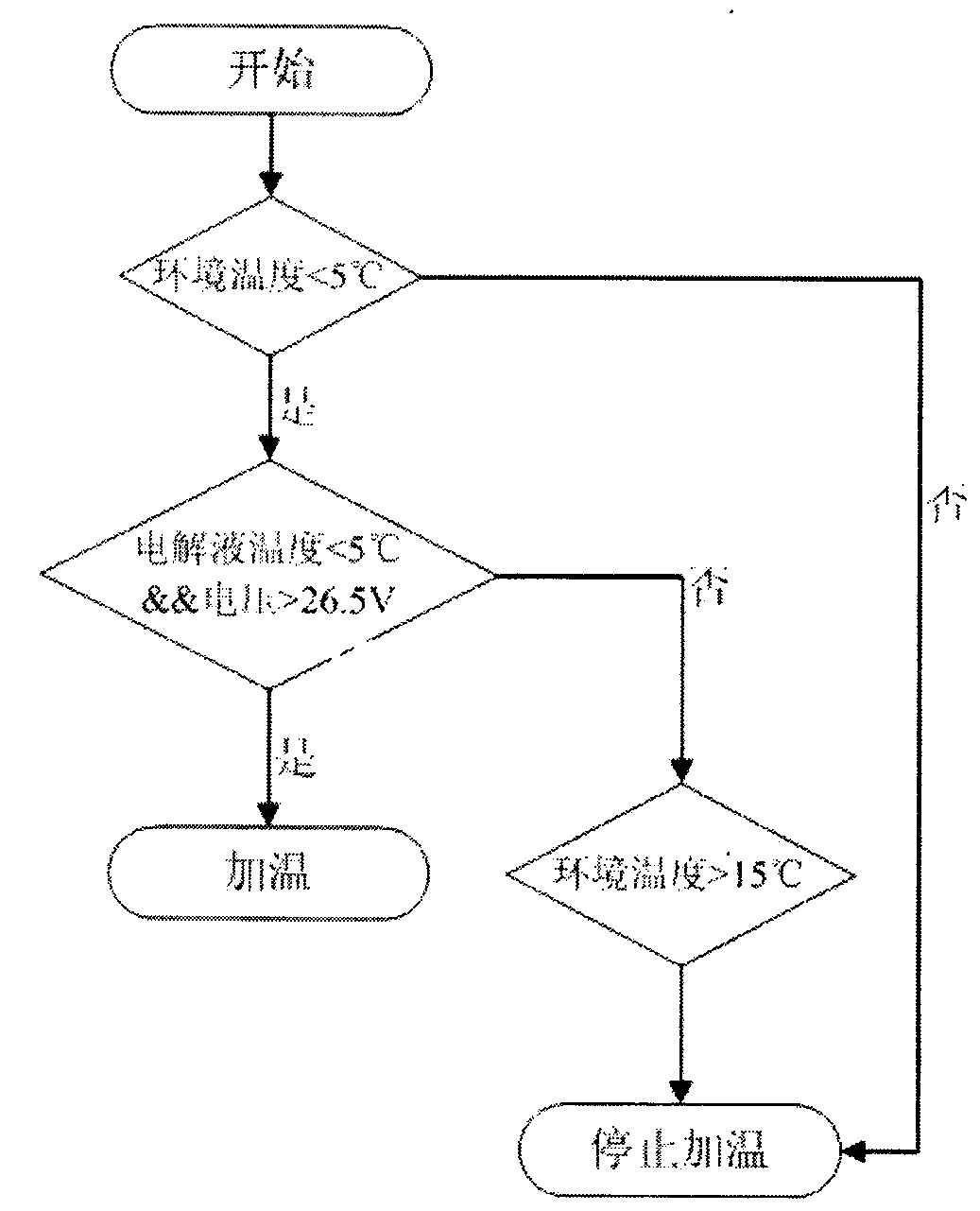

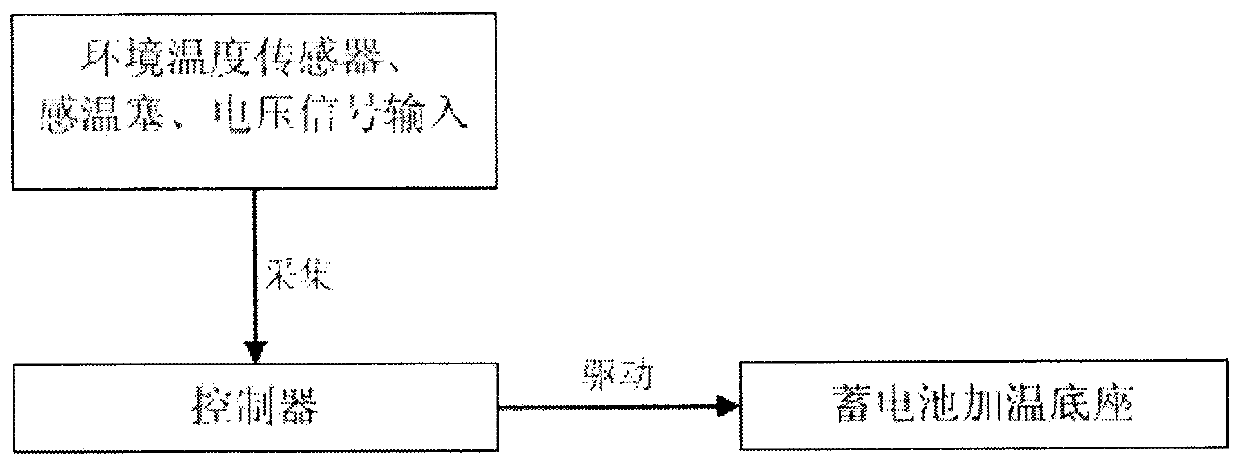

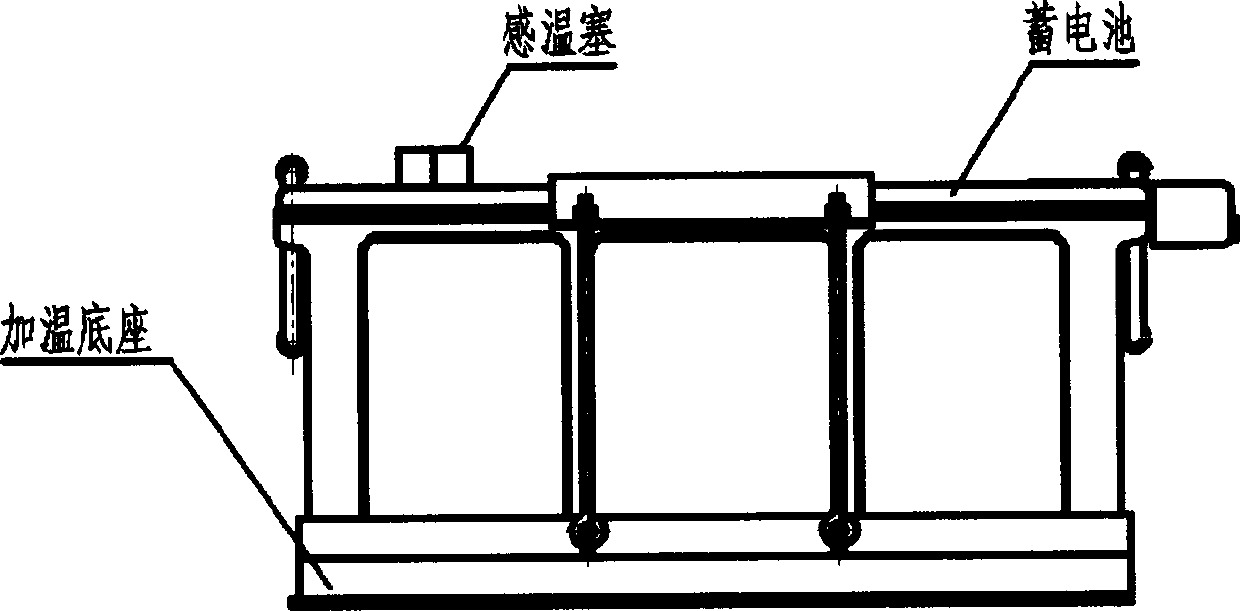

[0021] Such as figure 2 , 3 , 4, and 5 show a multi-stage automatic heating system for vehicles, including: a controller, a temperature sensing plug, an ambient temperature sensor, a heating base and a storage battery; the controller drives the heating base to The storage battery is heated; the temperature-sensing plug is arranged on the top of the storage battery; the heating base is located at the bottom of the storage battery; the controller collects the temperature signals of the ambient temperature sensor and the temperature-sensing plug sensor, And the voltage signal of the storage battery, through logical judgment, automatically drives the heating base to heat the storage battery. Wherein, the size of the storage battery is: the length is 413mm to 510mm, the width is 171mm to 212mm, the height is 207mm to 210mm, and the total height is 226mm to 241mm; the weight of the storage battery is 26.5kg to 42.5kg; the heating base The size is 420mm to 525mm in length, 180mm t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com