Horizontal table type dish washing machine

A dishwasher and horizontal technology, applied in the field of household dishwashers, can solve the problems of unfavorable cleaning, large space occupation, incomplete cleaning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] best practice

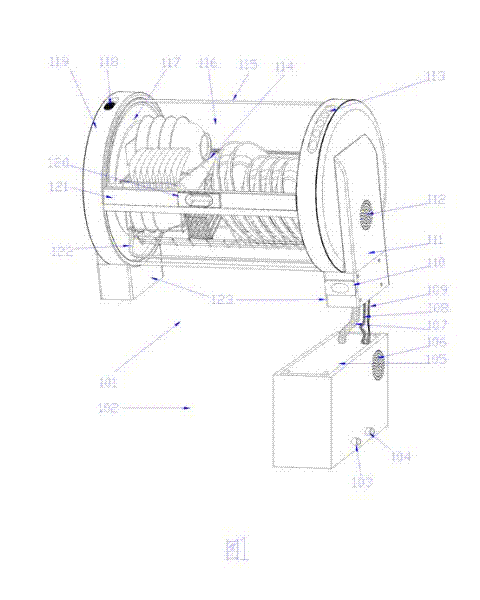

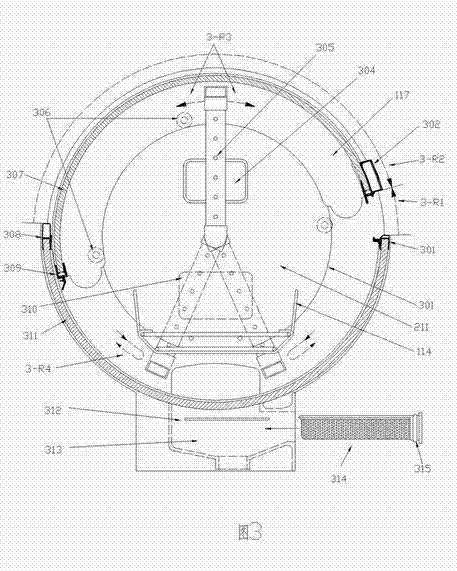

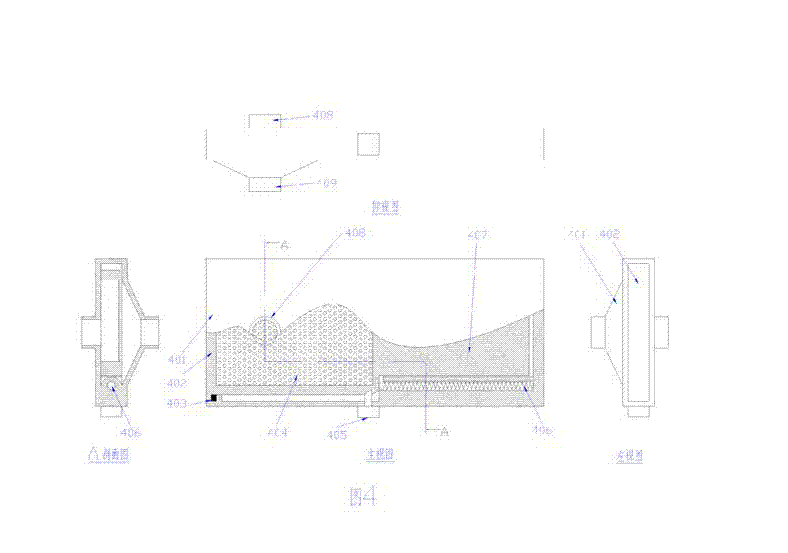

[0069] exist figure 1 , 2 , 3, the washing box (101) is placed on and above the self-cleaning water tank (102) or above the table, and the two are connected by high-pressure water pipes (108), circulating water pipes (107) and electrical circuits (109). It specifically includes: the washing box (101) is divided into three parts: the washing chamber (116), the left accessory box (119) and the right accessory box (111), and consists of a sliding door (115), a transverse arm spray pipe (122), a tableware rack (114), manual drawer type filter box (110), ultraviolet tube (215) and the sterilizing device that quartz glass window (304) forms, detergent dispenser (216), blower fan (212) and heating element B (204 ) consists of a heating device, an exhaust fan (218), a control panel (113), a synchronous motor (217), a rotary sealing joint (214), a light source (210) and a reed switch (209). Legs (123) are all extended from the bottom of the left and rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com