Fully automatic multi-station glass bottle making machine

A multi-station, bottle-making machine technology, applied in the direction of special transmission machinery for glass blowing machines, etc., can solve the problems of low degree of automation, high labor intensity and high ambient temperature, achieve high degree of automation, low manufacturing cost, design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

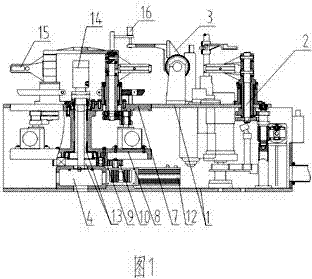

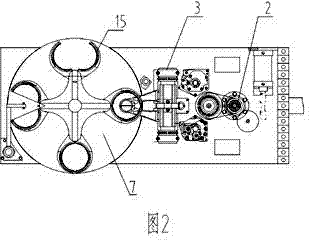

[0016] Taking the fully automatic four-station glass bottle making machine as an example, it consists of frame 1, primary mold mechanism 2, turning mechanism 3 and four-station molding mechanism; primary mold mechanism 2, turning mechanism 3 and four-station molding mechanism Mechanism mounted on rack 1, see figure 1 , figure 2 .

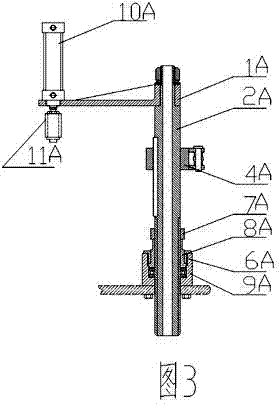

[0017] The four-station molding mechanism consists of a machine base 4, a turntable mechanism, a forward blowing mechanism 16, four clamp mechanisms 15 and four mold seats. The turntable mechanism consists of an upper turntable 7, a lower turntable 8, a passive transmission gear 9, and a main drive Gear 10, reducer, servo motor 12, hollow pipe-through shaft 13, and rotary joint 14. Hollow pipe-through shaft 13 is installed on machine base 4 through bearings and bearing seats. Hollow column is arranged on lower turntable 8, and hollow pipe-through shaft The shaft 13 is set in the hollow column of the lower turntable 8 through the bearing and the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com