Post-tensioned pre-stressed compound uplift pile

A technology of post-tensioned prestressed and uplift piles, which is applied to sheet pile walls, buildings, and foundation structure engineering, can solve the problems of waste of materials, large piles, and uneconomical problems, and achieve obvious economic benefits and small piles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

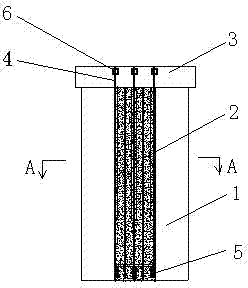

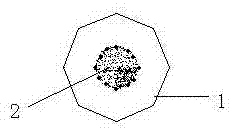

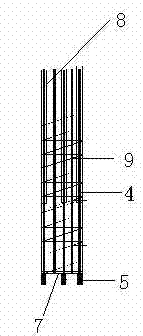

[0018] Such as figure 1 , 2 As shown, the present invention includes a cement-soil mixing pile 1, a reinforced concrete columnar core 2 in the cement-soil mixing pile 1, and a cap surface 3 arranged at the upper end of the pile. The inner coaxial line of the columnar core 2 is provided with a post-tensioned prestressed steel cable 4, and the steel cable 4 is arranged around the peripheral part of the columnar core 2, and is arranged at intervals with the pre-tensioned prestressed steel bars of the steel cage skeleton 9 in the columnar core , which is connected to the steel cage skeleton 9.

[0019] Such as figure 1 , 3 As shown, the post-tensioned steel cable 4 is provided with an enlarged head 5 , and the enlarged head 5 is arranged at the lower end of the steel cable 4 . In this embodiment, the expanding head 5 is an extruded anchor, and a steel backing plate 7 is provided on the post-tensioned steel cable 4 above the extruded anchor. still as figure 1 , 3 As shown, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com