See-through pile plate combined type sea inlet road structure

A pile-plate combination and sea road technology, which is applied in infrastructure engineering, roads, roads, etc., can solve the problems of not meeting the requirements of beach oil exploration, lack of operating ships in shallow water areas, and restricting the development of beach and land oil fields. The effect of small maintenance workload, short construction period and strong scour resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

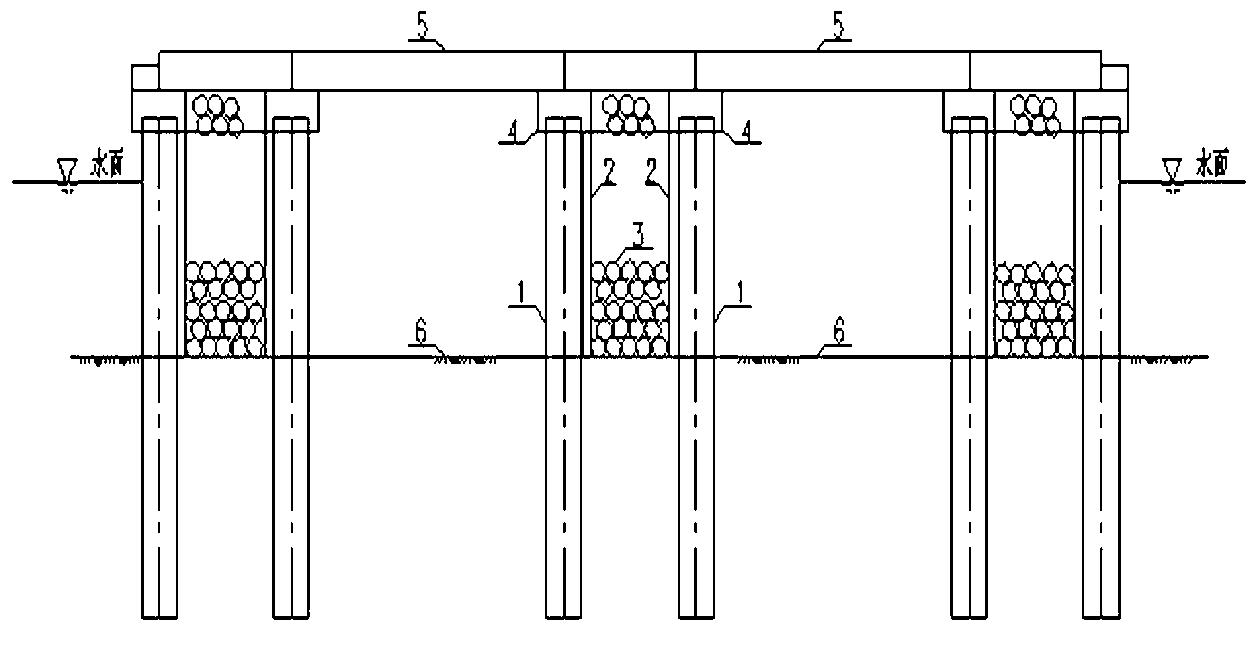

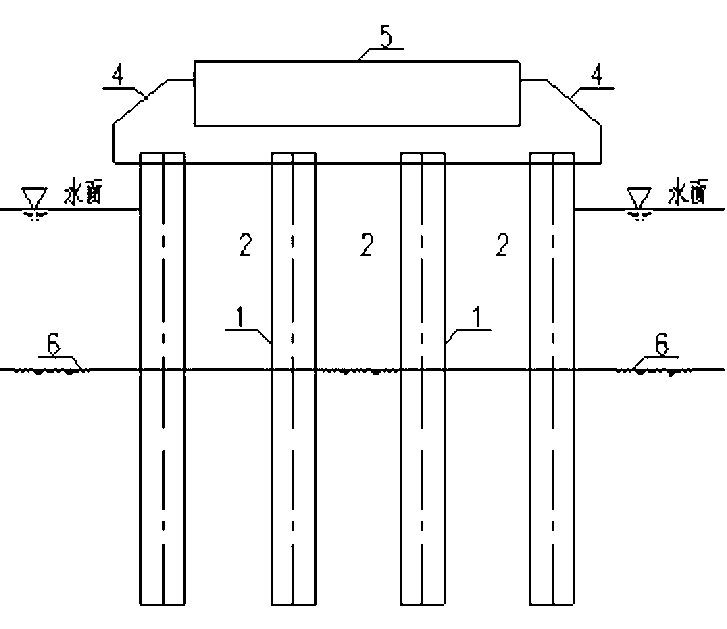

[0026] In order to further disclose the technical solutions of the present invention, the following will be described in detail through examples in conjunction with the accompanying drawings:

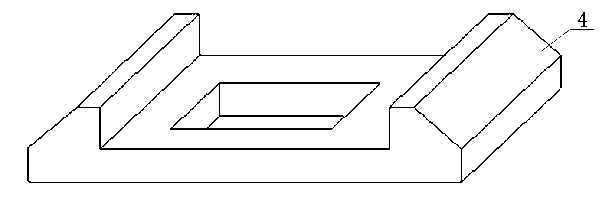

[0027] The present invention comprises reinforced concrete pipe columns, reinforced concrete baffles 2, riprap 3, caps 4 and panels 5, and is characterized in that reinforced concrete pipe piles 1 are arranged side by side laterally, and each row of reinforced concrete pipe piles 1 has at least two pieces, and every two The row is a subgrade support pier, and the reinforced concrete pipe piles 1 of each subgrade support pier are arranged symmetrically. The inner side of each subgrade pier is provided with a reinforced concrete baffle 2 inserted into the seabed mud surface 6 to form a rectangular space filled with riprap 3; the cap 4 between the subgrade pier and the subgrade pier There is a panel 5 on it, and the two ends of the panel 5 are inlaid in the middle of the cap 4, and a water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com