Lubricating device for gas turbine multi-stage transmission reducer

A lubricating device and gas turbine technology, applied in the direction of gear lubrication/cooling, etc., can solve the problems of high-position bearings that cannot be lubricated, small in size and weight, and occupy a large space, so as to eliminate hidden dangers of oil leakage, improve safety, and prolong service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

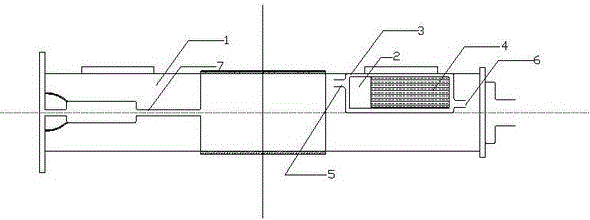

[0008] exist figure 1 In the shown lubricating device for a gas turbine multi-stage transmission reducer, it is characterized by a motor 2, an oil reservoir 3, a lubricating oil 4, an oil reservoir A end 6, an oil reservoir B end 5, The oil pipe 7 is composed of; the lubricating device is arranged inside the reducer 1, and a sealed oil reservoir 3 is arranged inside the reducer 1, and the oil reservoir 3 is arranged close to the inner wall of the reducer 1, and the braking is controlled by the motor 2. Lubricating oil 4 used for lubrication is installed in the oil storage 3, the A end 6 of the oil storage is connected to the shaft end pump, the B end 5 of the oil storage is connected to the oil pipes at the high bearings of each shaft of the reducer 1 7 are connected; the shaft end pump works, the lubricating oil enters the A terminal 6 of the oil storage from the shaft end pump, and then flows from the A terminal 6 of the oil storage to the B terminal 5 of the oil storage thr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap