Three-phase unequal-turns fractional slot concentrated winding

A concentrated winding and fractional slot technology, applied in the field of turn fractional slot concentrated winding, can solve problems such as low motor performance, and achieve the effects of excellent performance, easy implementation and high performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

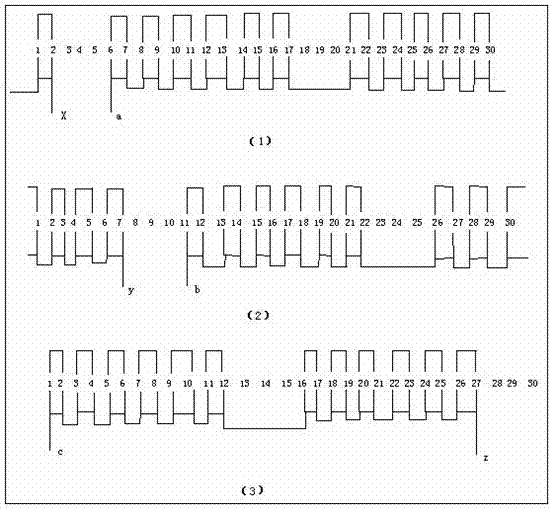

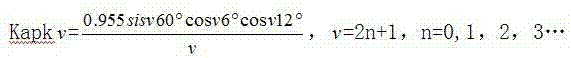

[0014] like figure 1 Shown is a three-phase unequal-turn-fraction-slot concentrated winding arrangement for a motor with 30 stator slots and 28 poles for a permanent magnet synchronous servo motor. The pitch of each coil is 1.

[0015] figure 1 (1) is the A-phase winding, consisting of 12 coils of ax, namely 6-7, 8-9, 10-11, 12-13, 14-15, 16-17; 21-22, 23-24, 25-26 , 27-28, 29-30, 1-2; fully open coils in series, including 4 coils, namely 6-7; 16-17; 21-22; 1-2; the number of turns of each coil is n turns, n is a natural number, each of the remaining 8 coils has 2n turns, the turns ratio of the two unequal turns is 2:1, the a end is drawn from the 6th slot, and the x end is drawn from the 2nd slot Slot lead;

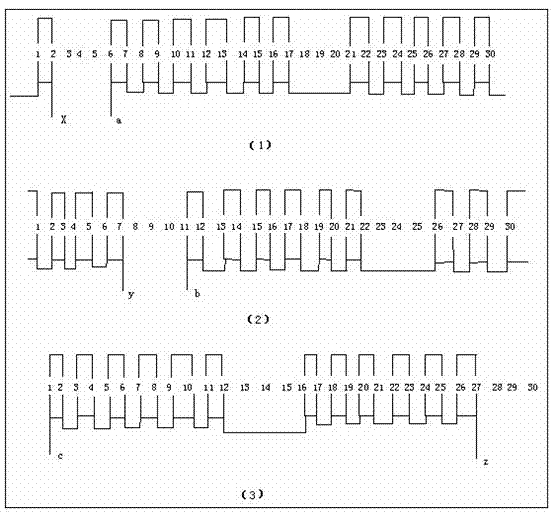

[0016] figure 1 (2) It is B-phase winding, consisting of 12 coils of by, namely 11-12, 13-14, 15-16, 17-18, 19-20, 21-22; 26-27, 28-29, 30-1 , 2-3, 4-5, 6-7; full opening coils are connected in series, including 4 coils, namely 11-12; 21-22; 26-27; 6-7; the number o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com