Plier

A technology of clamps and clamping teeth, which is applied in the direction of pliers, wrench, wrench, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

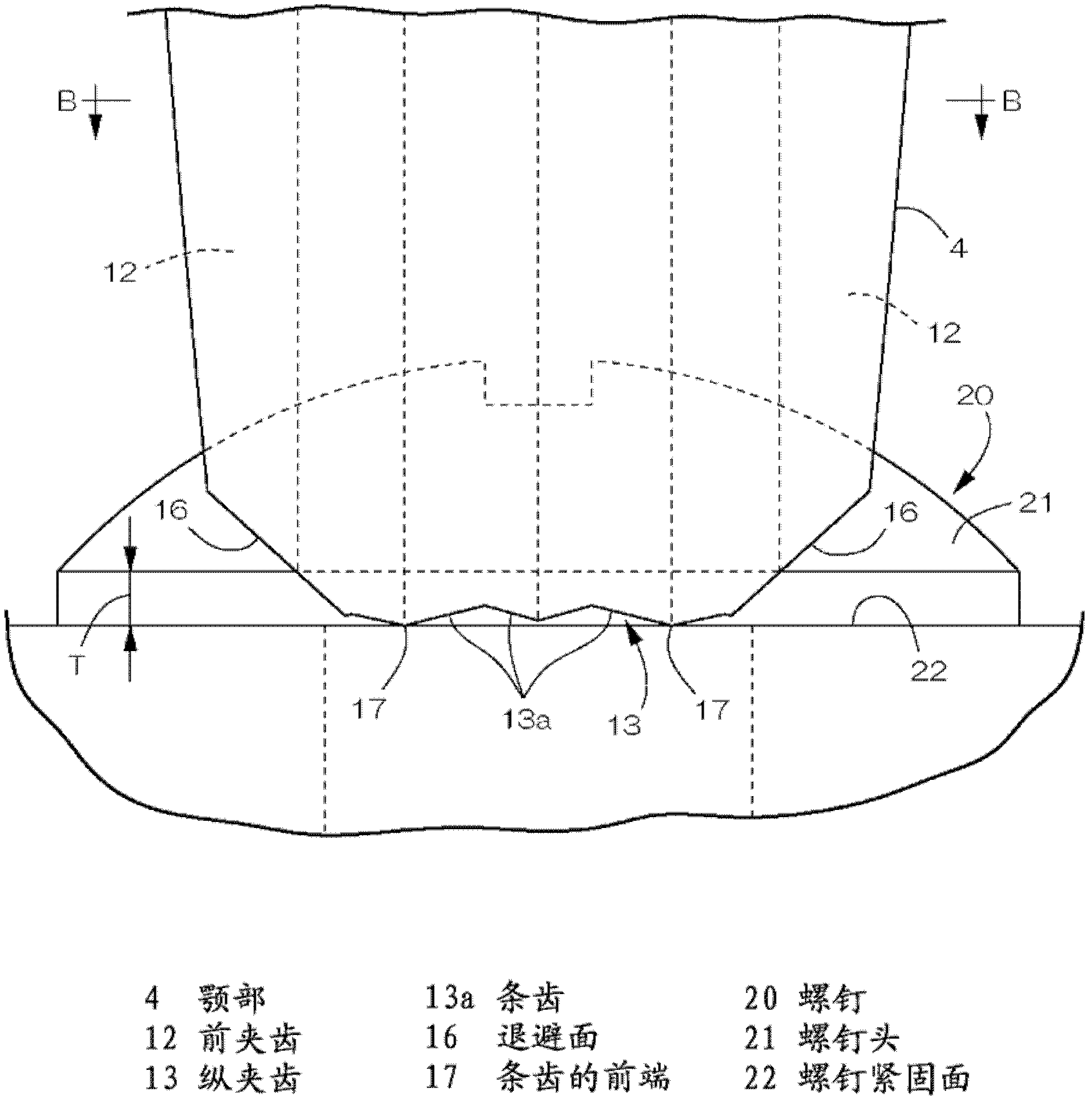

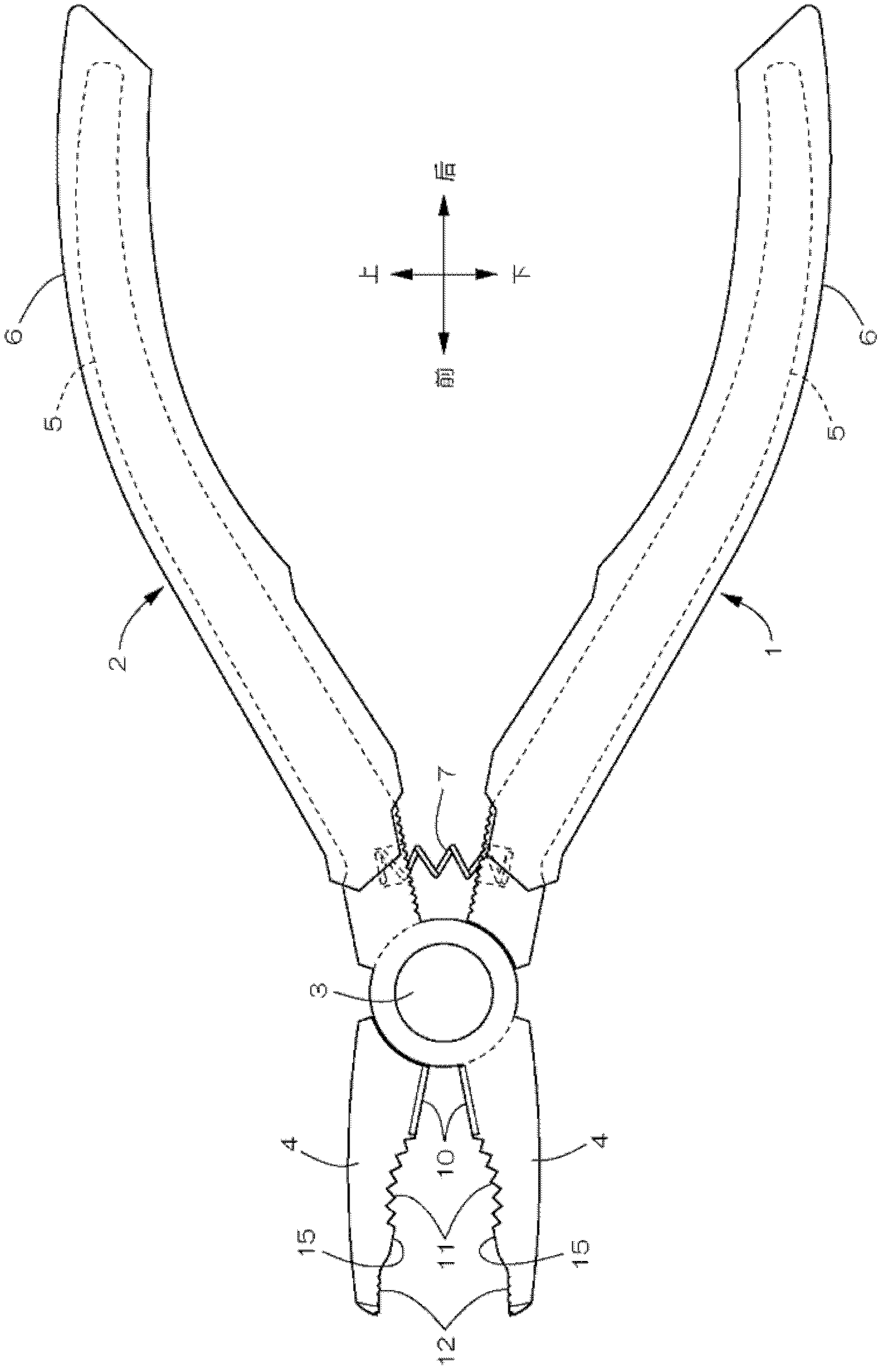

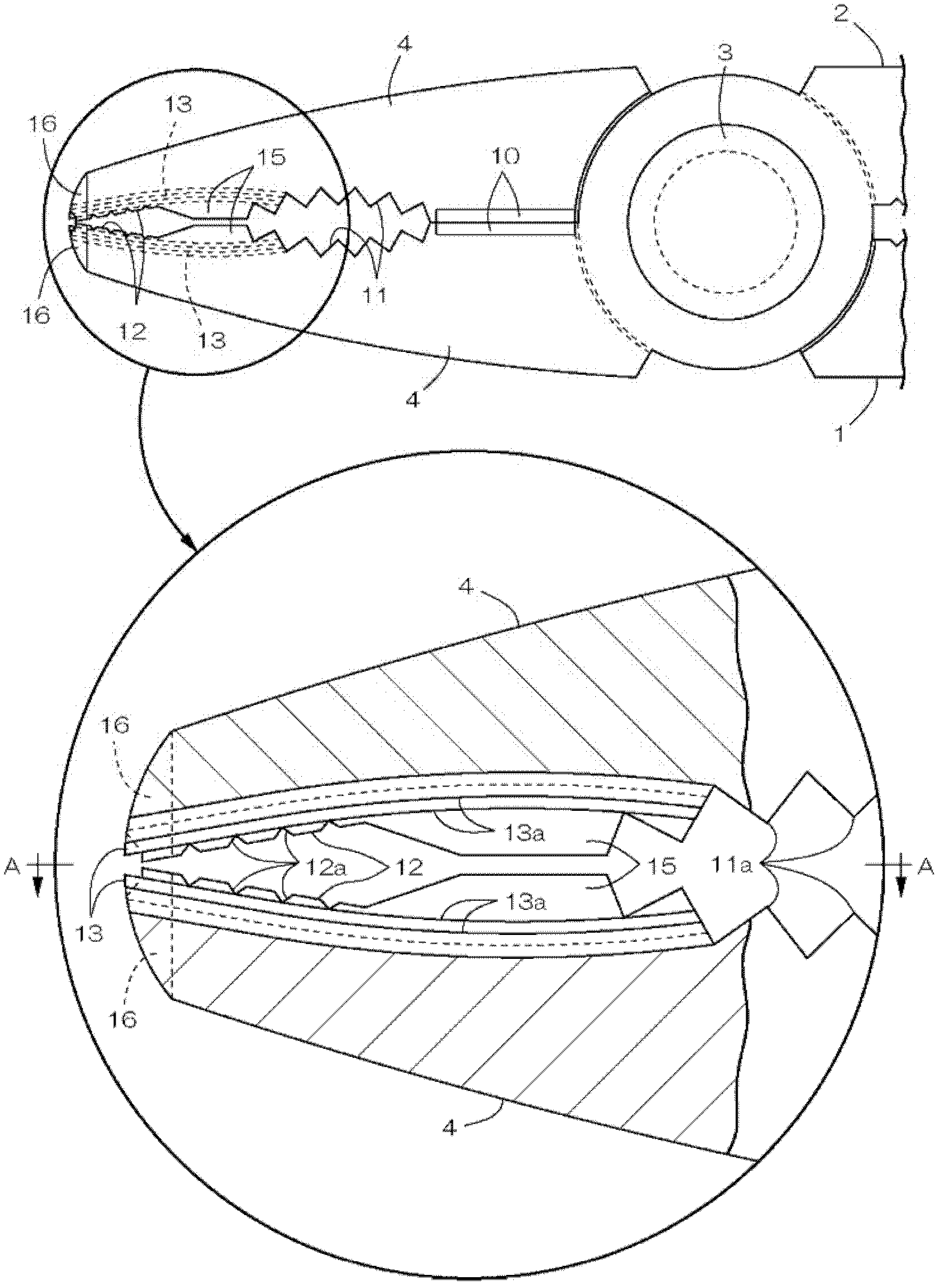

[0043] Figure 1 to Figure 8 It is an example which shows the pliers of this invention. exist figure 2 Among them, the clamp is configured by connecting the first arm 1 and the second arm 2 arranged in an X shape with a connecting shaft 3 so as to be relatively swingable. The two clamp arms 1, 2 are loaded by a compression coil (coil)-shaped expansion spring 7 for expansion. In addition, front and rear, left and right, and up and down in the present invention are based on figure 2 and Figure 4 The cross arrows shown are indicated by the text of front and rear, left and right, and up and down.

[0044] Each arm 1, 2 is made of a forged product having a jaw 4 at the front end and a handle 5 at the rear end, and the outer surface of the handle 5 is covered with a grip body 6 made of a plastic molded product. The above-mentioned expansion spring 7 is disposed near the intersection portion on the handle 5 side. On the facing surfaces of the respective jaws 4 , shear blades...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap