Method for purifying titanium material

A raw material, pure titanium technology, applied in the direction of process efficiency improvement, sustainable manufacturing/processing, metal processing, etc., can solve the problems of not describing experimental conditions, difficult to expect oxygen reduction effect, and obtaining data, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

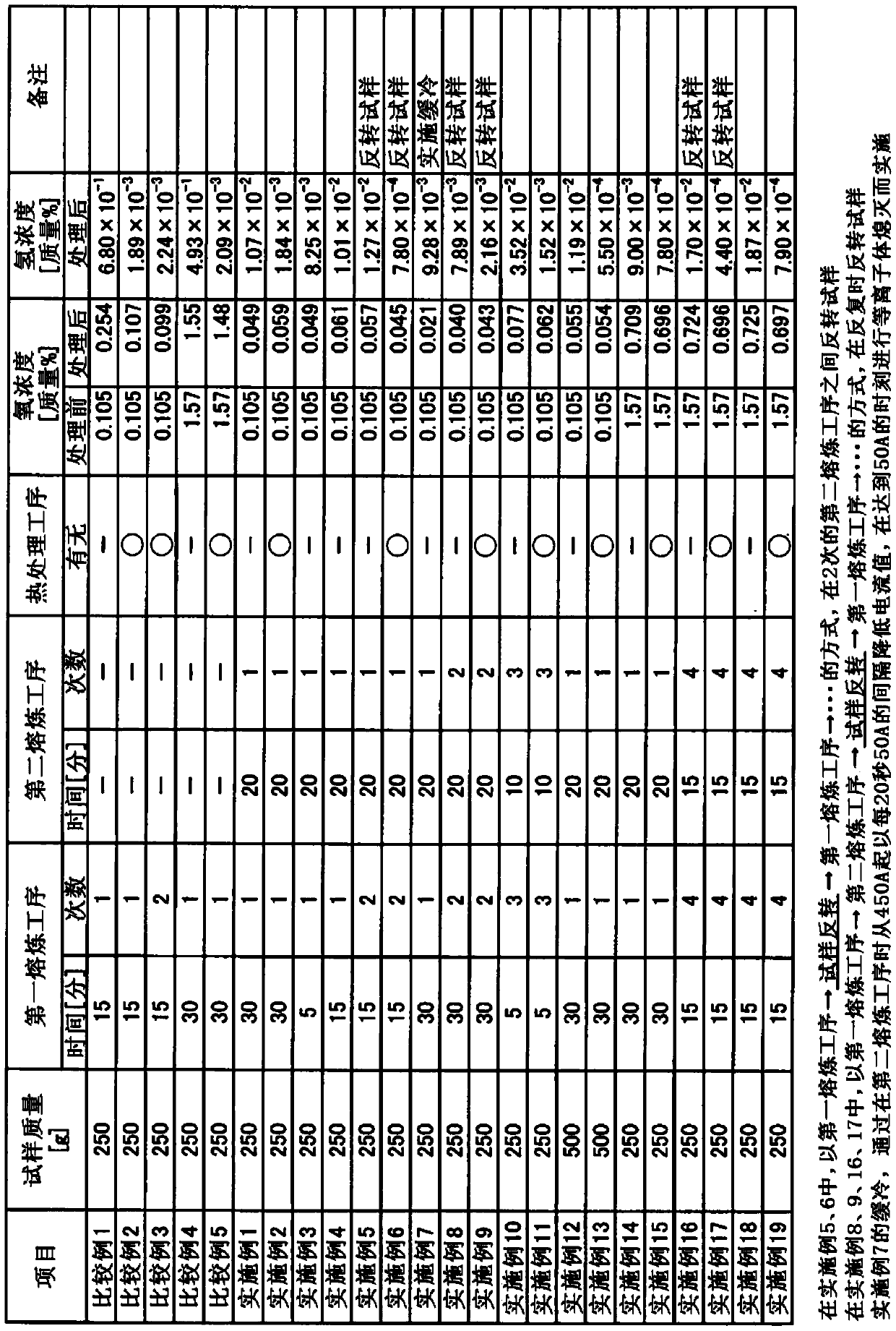

Examples

Embodiment Construction

[0019] The inventors of the present invention sought to find a titanium raw material capable of reliably removing light elements contained in the titanium raw material, especially oxygen, from a titanium raw material whose main component is titanium, which is very easily combined with light elements such as oxygen and nitrogen. The refining method of the material has been intensively studied.

[0020] As a result, it was found that by performing the first smelting step of melting the titanium raw material under an inert gas atmosphere containing a certain amount of hydrogen to introduce hydrogen, and then melting the titanium raw material under an inert gas atmosphere, the In the second smelting step in which the hydrogen introduced in the first step is removed together with the contained oxygen, the oxygen contained in the titanium raw material can be reliably removed, and the present invention has been completed.

[0021] In addition, it was also confirmed that hydrogen intr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com