Preparation technology of mianxiang jinyun Tie Guanyin tea

A production process, the technology of Tieguanyin, applied in tea treatment before extraction, etc., can solve the problems of not being easy to store, the taste of tea is not mellow and long enough, and easy to hurt the stomach, etc., and achieve the effect of long-lasting fragrance, mellow tea soup and mellow taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

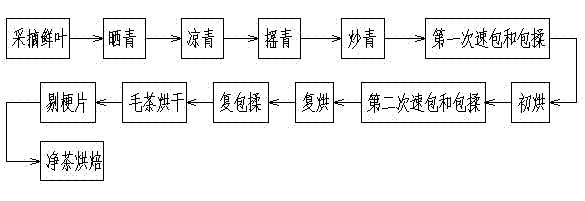

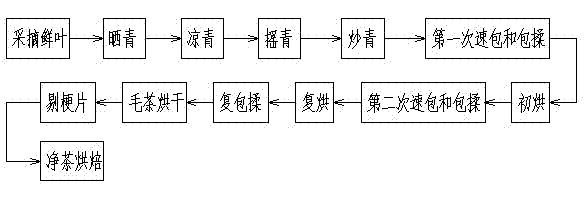

Image

Examples

Embodiment 1

[0037] Embodiment 1: As shown in the figure, the production process of Tieguanyin with soft fragrance and golden rhyme in this embodiment includes the following steps:

[0038] A. Picking fresh leaves, according to the standard of 2-3 leaves in the small opening during the picking process, the quality of the tea obtained is the best;

[0039] B, sun drying, fresh leaves are air-dried to weight loss of 7%, certainly in specific implementation, fresh leaves air weight loss can be controlled within 7~10%, and the results of sun-drying are all better;

[0040] C, cool green, put the tealeaves after sun-dried green into the room to spread cool, and the cool time of spread is generally 50 minutes;

[0041] D, shaking green, shaking green comprises the following steps:

[0042] (1) Once shaken, the shaking time is 8 minutes. After shaking, take out the tea leaves and let them cool for 1 hour. When shaking, the water content of the tea leaves is more, and the tea leaves are easy to b...

Embodiment 2

[0065] Embodiment 2: As shown in the figure, the production process of Tieguanyin with soft fragrance and golden rhyme in this embodiment includes the following steps:

[0066] A. Picking fresh leaves, according to the standard of 2-3 leaves in the small opening during the picking process, the quality of the tea obtained is the best;

[0067] B, sun drying, fresh leaves are air-dried to weight loss of 7%, certainly in specific implementation, fresh leaves air weight loss can be controlled within 7~10%, and the results of sun-drying are all better;

[0068] C, cool green, put the tealeaves after sun-dried green into the room to spread cool, and the cool time of spread is generally 50 minutes;

[0069] D, shaking green, shaking green comprises the following steps:

[0070] (1) Once shaken, the shaking time is 9 minutes. After shaking, take out the tea leaves and let them cool for 1.2 hours. When shaking, the tea leaves have more water content, and the tea leaves are easy to break...

Embodiment 3

[0092] Embodiment 3: As shown in the figure, the production process of Tieguanyin with soft fragrance and golden rhyme in this embodiment includes the following steps:

[0093] A. Picking fresh leaves, according to the standard of 2-3 leaves in the small opening during the picking process, the quality of the tea obtained is the best;

[0094] B, sun drying, fresh leaves are air-dried to weight loss of 7%, certainly in specific implementation, fresh leaves air weight loss can be controlled within 7~10%, and the results of sun-drying are all better;

[0095] C, cool green, put the tealeaves after sun-dried green into the room to spread cool, and the cool time of spread is generally 50 minutes;

[0096] D, shaking green, shaking green comprises the following steps:

[0097] (1) Shake the green leaves for 10 minutes. After shaking the green leaves, take out the tea leaves and let them cool for 1.5 hours. When you shake them, the tea leaves have a lot of water content, and the tea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com