Dry magnetic separator based on fluidization

A magnetic separator and fluidization technology, applied in the fields of magnetic separation, chemical instruments and methods, solid separation, etc., can solve the problems of poor feeding uniformity, difficulty in adjusting the feeding amount, and high consumption of magnetic materials, etc. Achieve the effect of small occupied space, reduced loss of magnetic materials, and no severe friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

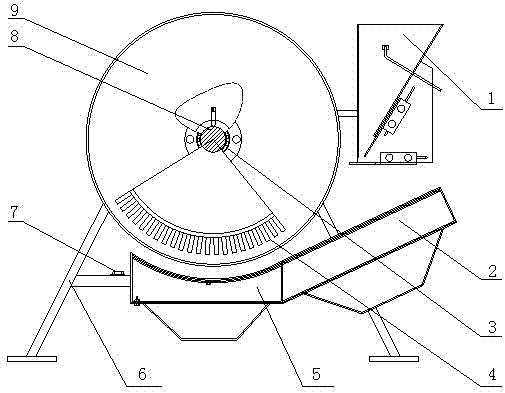

[0012] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

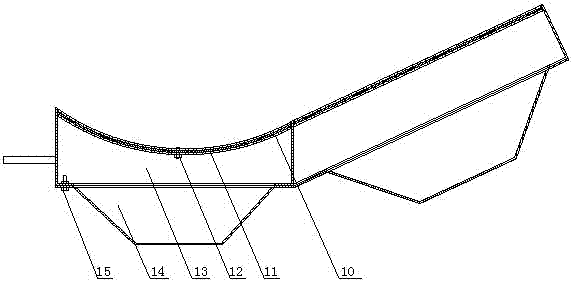

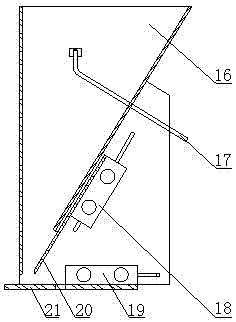

[0013] The fluidized dry magnetic separator based on the present invention is mainly composed of a feeding device 1, a magnetic separation drum 9, and a fluidized separation tank 5. The magnetic separation drum 9 is arranged obliquely, and the magnetic separation drum 9 is arranged obliquely. The angle is 3-10°. The below of the magnetic separation drum 9 is provided with a fluidized separation tank 5 having the same inclination angle, and the front end side of the magnetic separation drum 9 is provided with a feeding device 1 feeding to the front portion of the fluidized separation tank 5; The chemical separation tank 5 includes a base frame 13 on which an arc-shaped air distribution plate 10 with a filter cloth 11 sandwiched in the middle is provided. Groove 2, pedestal 13 bottom is provided with air chamber 14; Described feeding device 1 comprises wedge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com