Full-contact 180-degree plate turnover machine

A full-contact, turning machine technology, applied in the direction of turning objects, pile separation, thin material processing, etc., can solve the problems of lack of guidance and positioning, occupying large plant space, staff injuries, etc., to reduce smashed foundations. The risk of the seat, saving the space of the workshop, and the effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

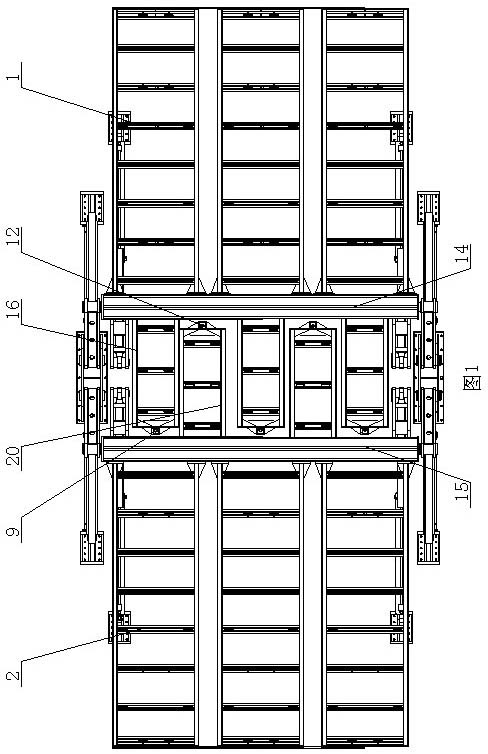

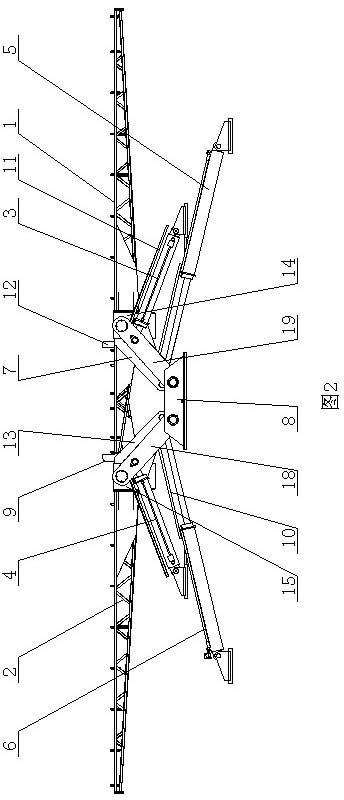

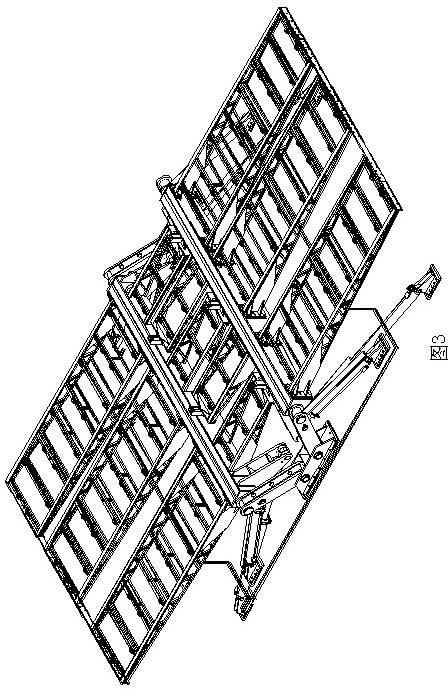

[0009] The full-contact 180-degree turning machine of the present invention includes a base 8 on which a first turning mechanism and a second turning mechanism are installed, and the first turning mechanism and the second turning mechanism are distributed left and right; the first turning mechanism is composed of The first overturning frame 1, the first connection seat 14, the first swing bar 19, the first overturning drive device and the first tilting drive device are connected to form, and the first overturning frame 1 is fixedly installed on the first connection seat 14, and the first connection seat 14 A first fork 19 is respectively installed at both ends, and the two first fork 19 are parallel, and the two ends of each first fork 19 are respectively hinged with the base 8 and the first connecting seat 14; A tilting drive device, the executive part of the first tilting drive device is hinged with the first swing rod 19, and the first swing rod 19 can be driven by the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com