Integrally-formed carbon fiber spoke and preparation method thereof

A technology of carbon fiber and carbon fiber prepreg, which is applied in the direction of spoked wheels, wheel manufacturing, and wheels made of non-metallic materials. The effect of structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

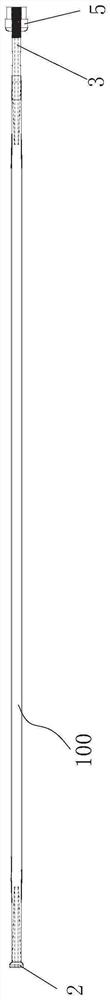

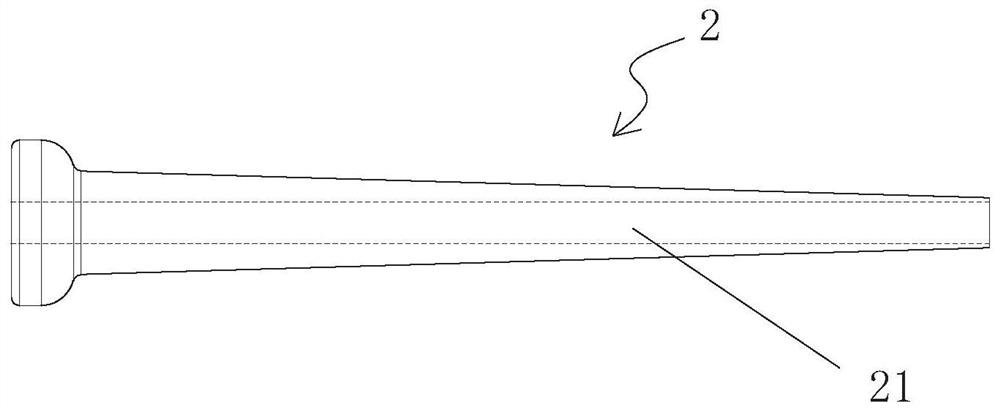

[0050] Example: see Figure 1 to Figure 16, an integrally formed carbon fiber spoke, which includes a spoke inner core made of carbon fiber, that is, a carbon fiber core 1, a second metal part 3 that can be connected to a rim, that is, a tooth cap, and a first metal that can be connected to a hub. Part 2 is the cap head and the carbon fiber prepreg layer 4. The tooth cap and the cap head are provided with a through installation hole, and the installation hole 31 of the tooth cap and the installation hole 21 of the cap head are respectively fixedly sleeved in the inner core of the spoke. At both ends of the spoke, the inner core of the spoke, part of the metal cap and part of the cap are provided with a carbon fiber prepreg layer 4. The above-mentioned part of the metal cap refers to the connection area where the metal cap and the carbon fiber prepreg layer are combined. The part of the cap The head refers to the connection area where the cap head is combined with the carbon fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com