Blanking device for thin rolled plate

A technology of coiling and blanking, applied in thin material handling, strip winding, transportation and packaging, etc., can solve the problems of material surface scratches, manufacturing troubles, large space, etc., to achieve stable material discharge, improve efficiency, Small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

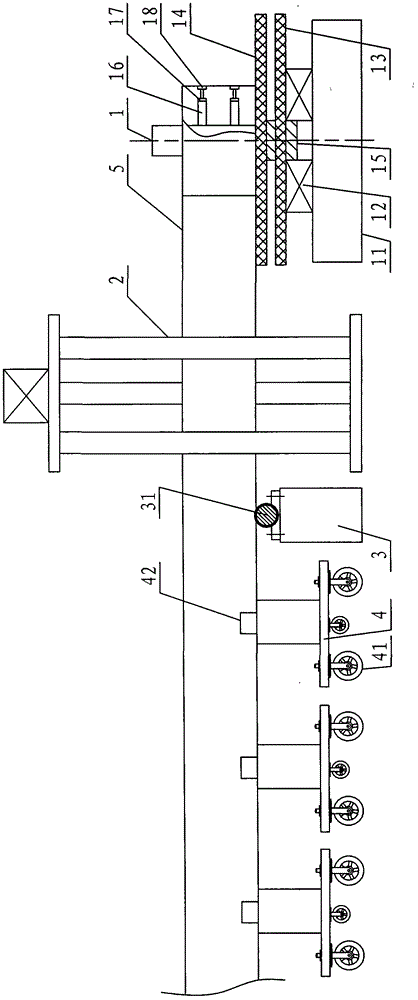

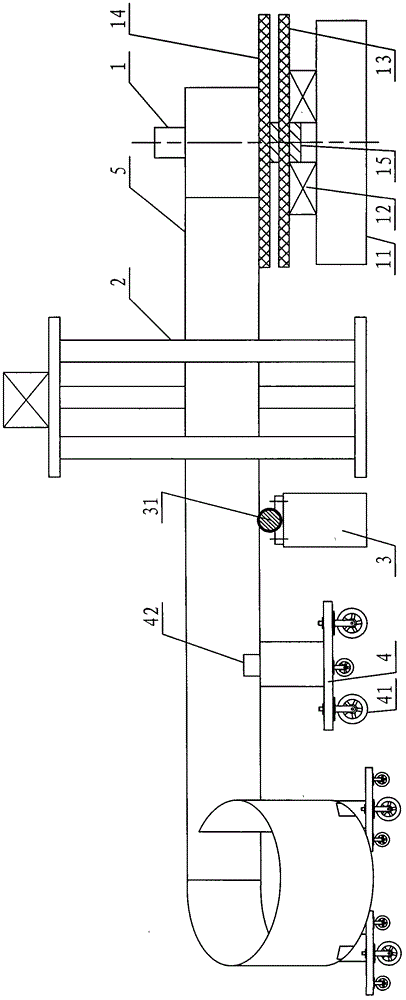

[0019] Such as Figure 1~2 In the shown embodiment, the unloading device for thin coiled boards according to the present invention includes a coiled board fixing mechanism 1, a vertical three-roll rounding machine 2, and a blanking track, which are arranged in sequence. The coiled board fixing mechanism 1 includes a basic Seat 11, the base 11 is made of channel steel and steel plate assembly welding, the plane bearing 12 is arranged on the base 11, the upper part of the bearing 12 is connected to the bottom plate a13, the bottom plate b14 is set above the bottom plate a13, and the rotating shaft a15 is fixed on the bearing 12, and the rotating shaft a15 is separately One end is fixed at the center of the lower part of the bottom plate b14, and the steel pipe is vertically welded at the middle position of the upper part of the bottom plate b14. The connection between the steel pipe and the bottom plate b14 is evenly provided with reinforcing ribs, and four branch pipes 16 are ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com