Torque measuring mechanism for spanner

A torque measurement and wrench technology, applied in the direction of wrenches, screwdrivers, manufacturing tools, etc., can solve the problems of fuzzy single digits, cumbersome operation and inconvenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

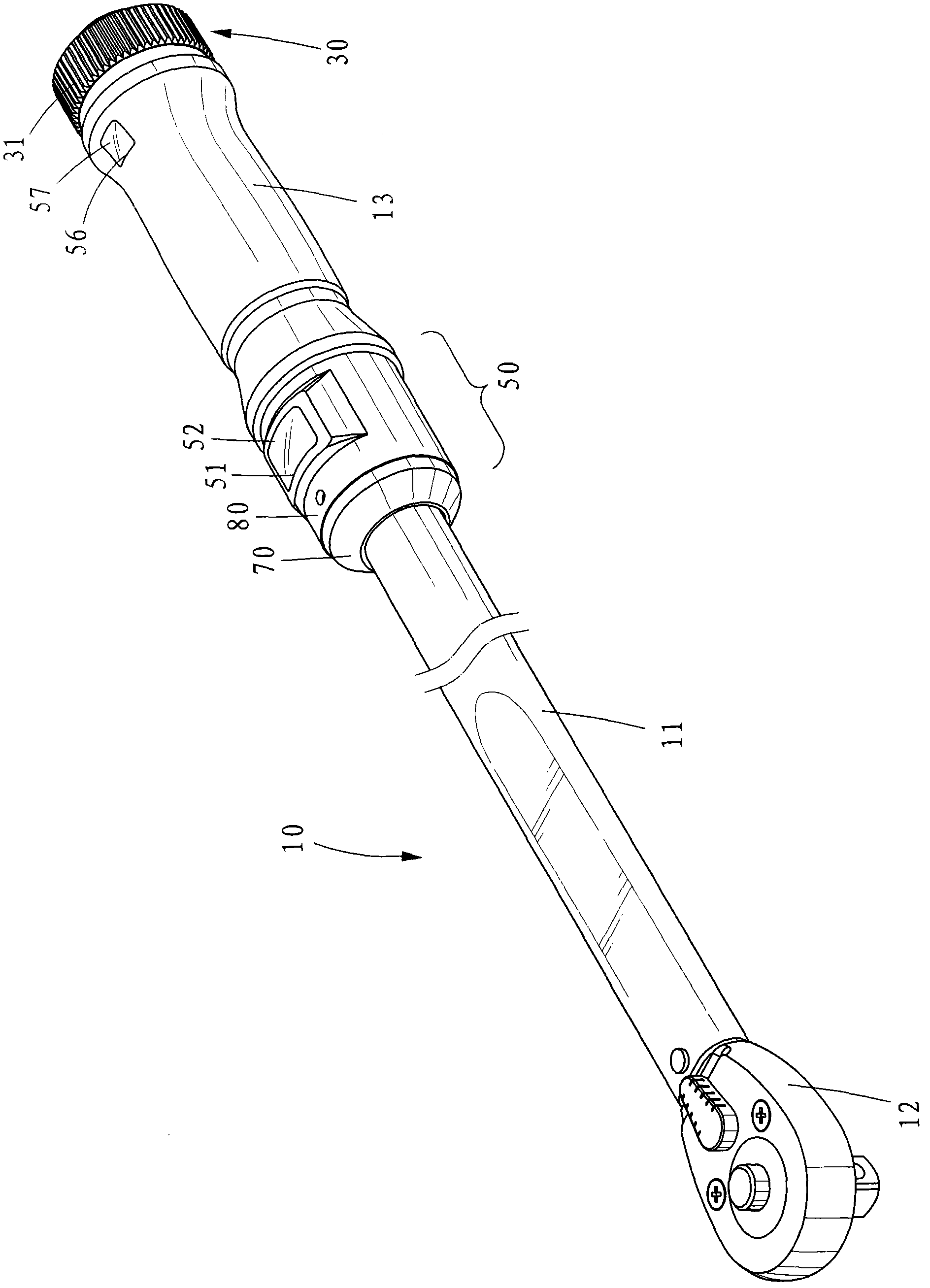

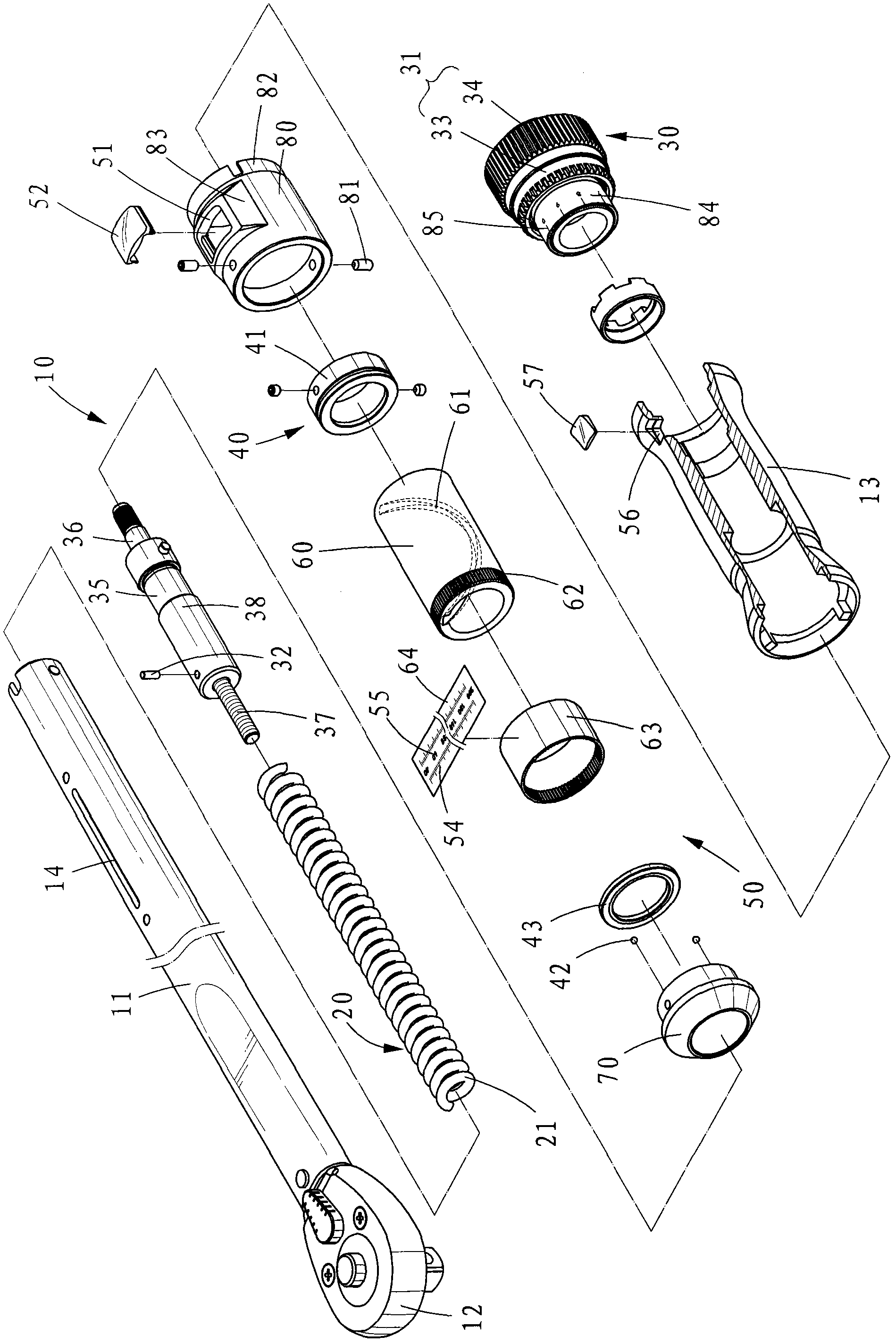

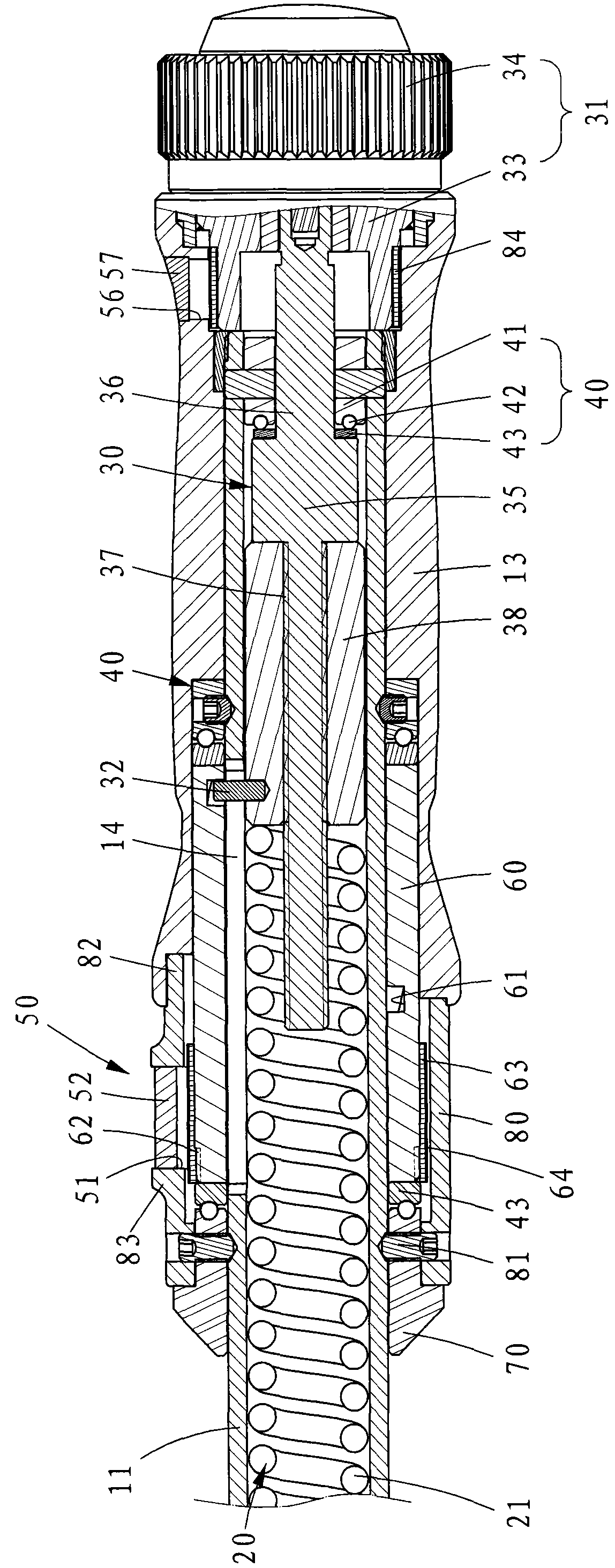

[0056] see Figure 1 to Figure 3 , its disclosed wrench 10 is connected with a head 12 at one end of the pipe fitting 11, and the other end of the pipe fitting 11 is connected with a handle 13, and is provided with an elongated hole 14 on the pipe body. Using the head 12 of the wrench 10 as a fulcrum, an external force is applied to the handle 13, and the swing pipe 11 reciprocates, that is, the torque can be transmitted to the workpiece through the head 12.

[0057] Wherein, the pipe 11 is connected with the head 12 through the torque output structure 20 . The torque output structure 20 includes a spring 21 embedded in the pipe fitting 11. For other structures, please refer to US Patent No. 4,870,879, which is not the focus of this case, so it will not be described in detail.

[0058] A torque adjusting devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com