Process method for combining prefabricated member by paving ceramic tiles in advance

A technology of prefabricated components and process methods, applied in the direction of manufacturing tools, ceramic molding machines, surface layering devices, etc., can solve problems such as labor-consuming and time-consuming, affecting the appearance of walls, and tiles falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] Below in conjunction with accompanying drawing, the present invention will be further described:

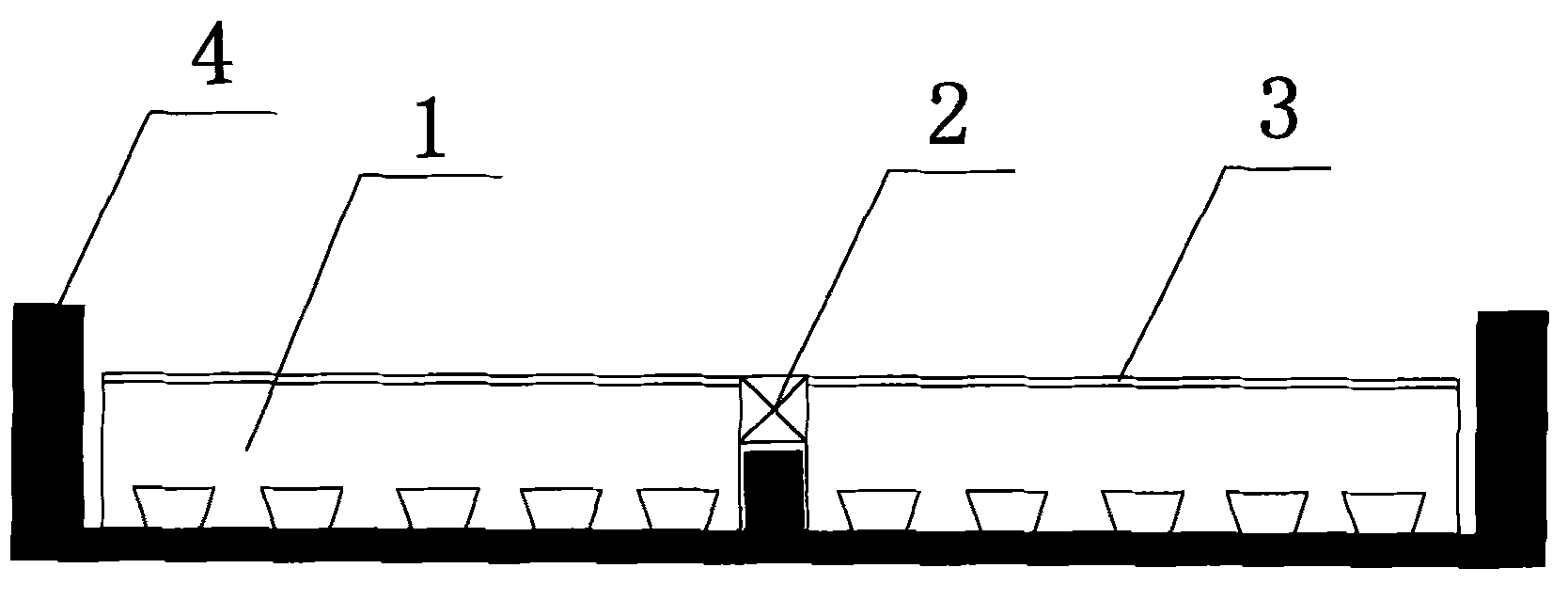

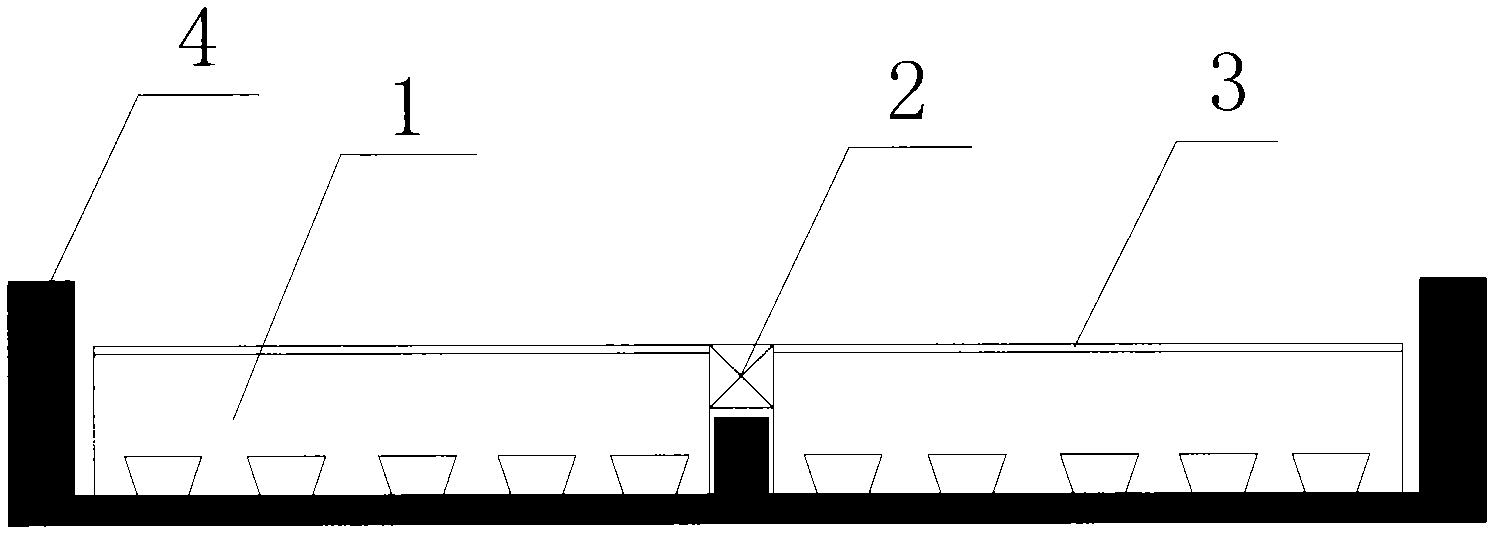

[0007] See attached figure 1 First, the bonding surface of the tile 1 and the wall is tiled on the bottom surface of the wooden formwork 4, and the tile 1 and the tile 1 are separated by a sponge strip 2, and then pasted on the surface of the tile 1 with a maintenance tape 3.

[0008] See attached figure 1 , first lay the bonding surface of the tile 1 and the wall on the bottom surface of the wooden formwork 4, separate the tile 1 and the tile 1 with a sponge strip 2, and then paste it on the surface of the tile 1 with a curing tape 3 to become a plate of the tile 1, According to the size of the prefabricated components, spread the 3 sides of the curing tape of the tile 1 plate on the pouring mold platform for splicing, put the steel cage into it and pour the concrete. After the concrete is poured, steam curing is carried out for 10 hours as a whole to form the tile 1 lai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com