Folding discharging rubber belt conveyor

A tape machine, folding technology, applied in conveyors, roads, road repair and other directions, can solve the problems of high economic cost of the whole machine, unacceptable to users, complex structure, etc., to achieve simple structure, safe effect and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to further understand the content of the invention, features and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

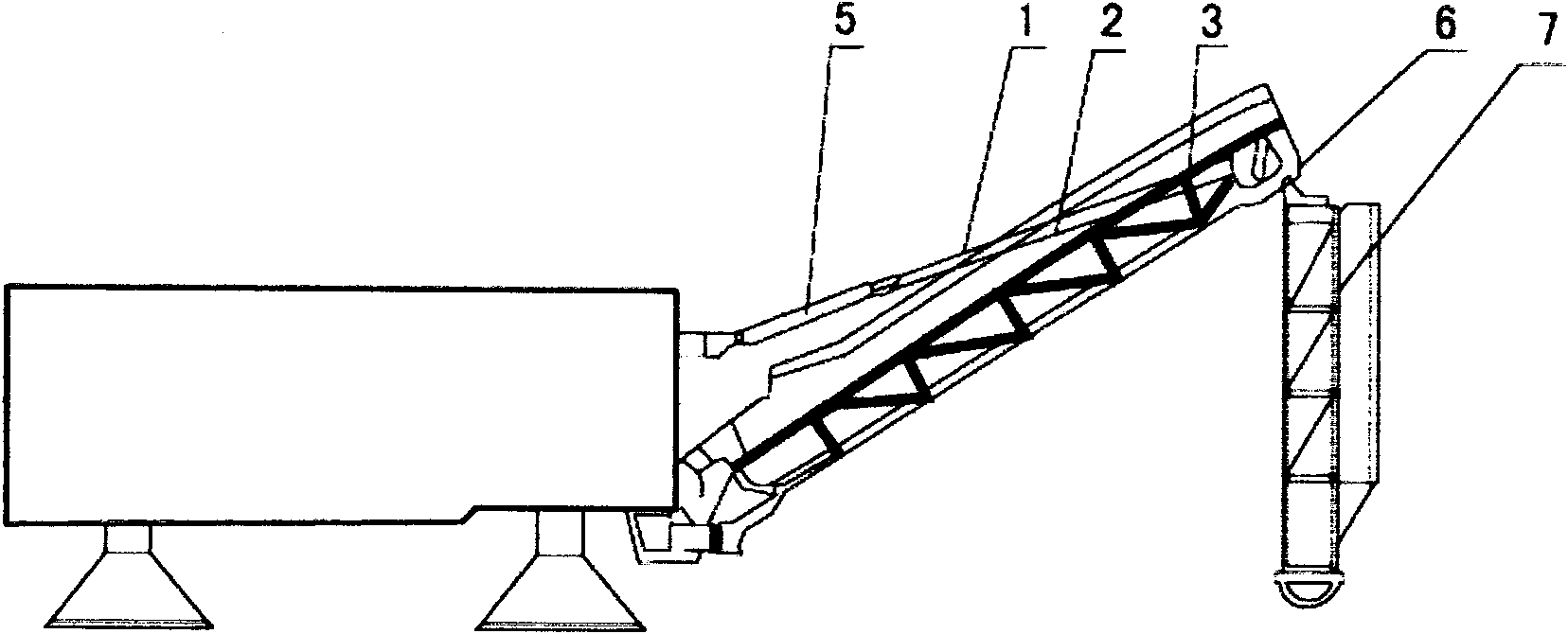

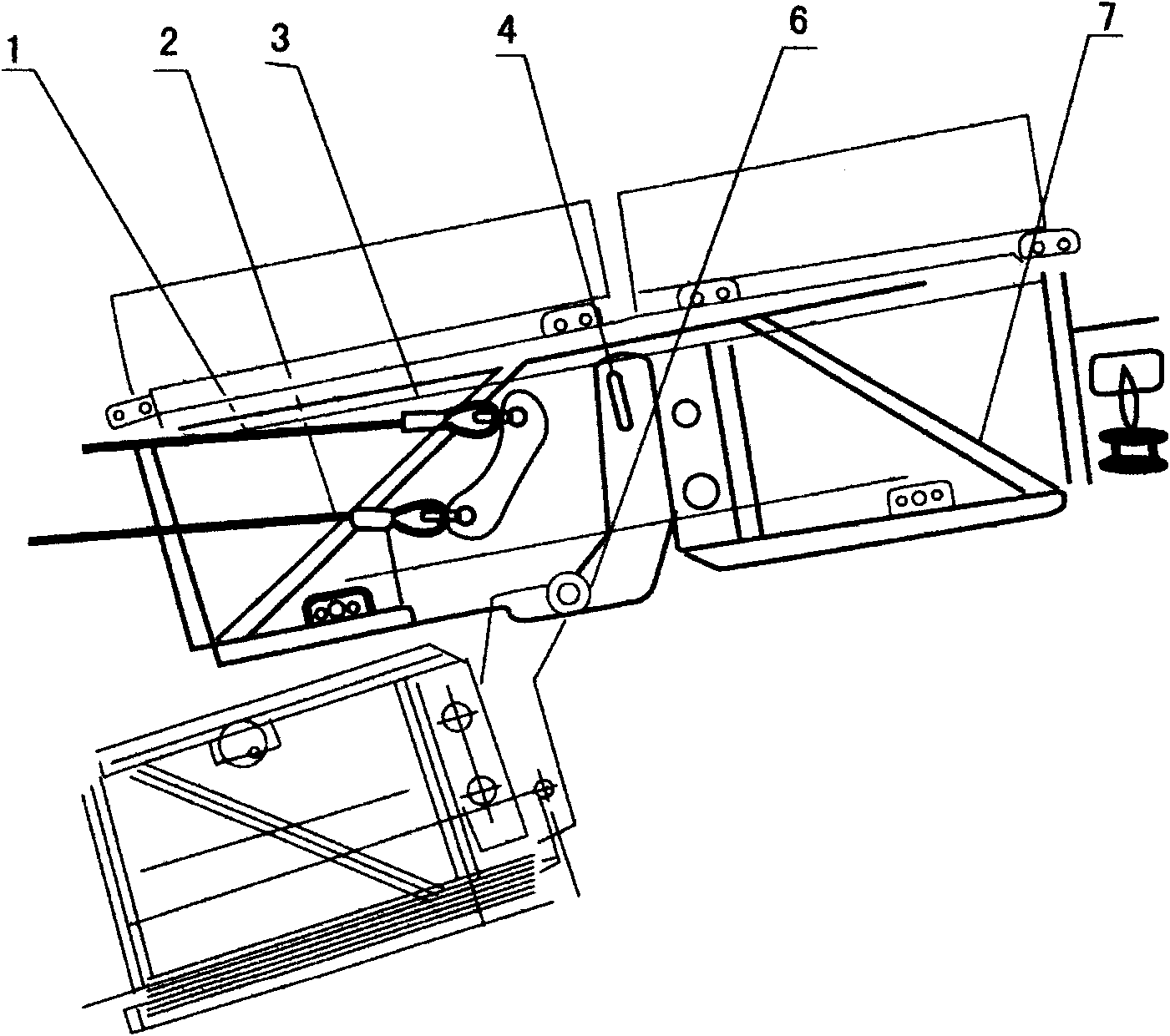

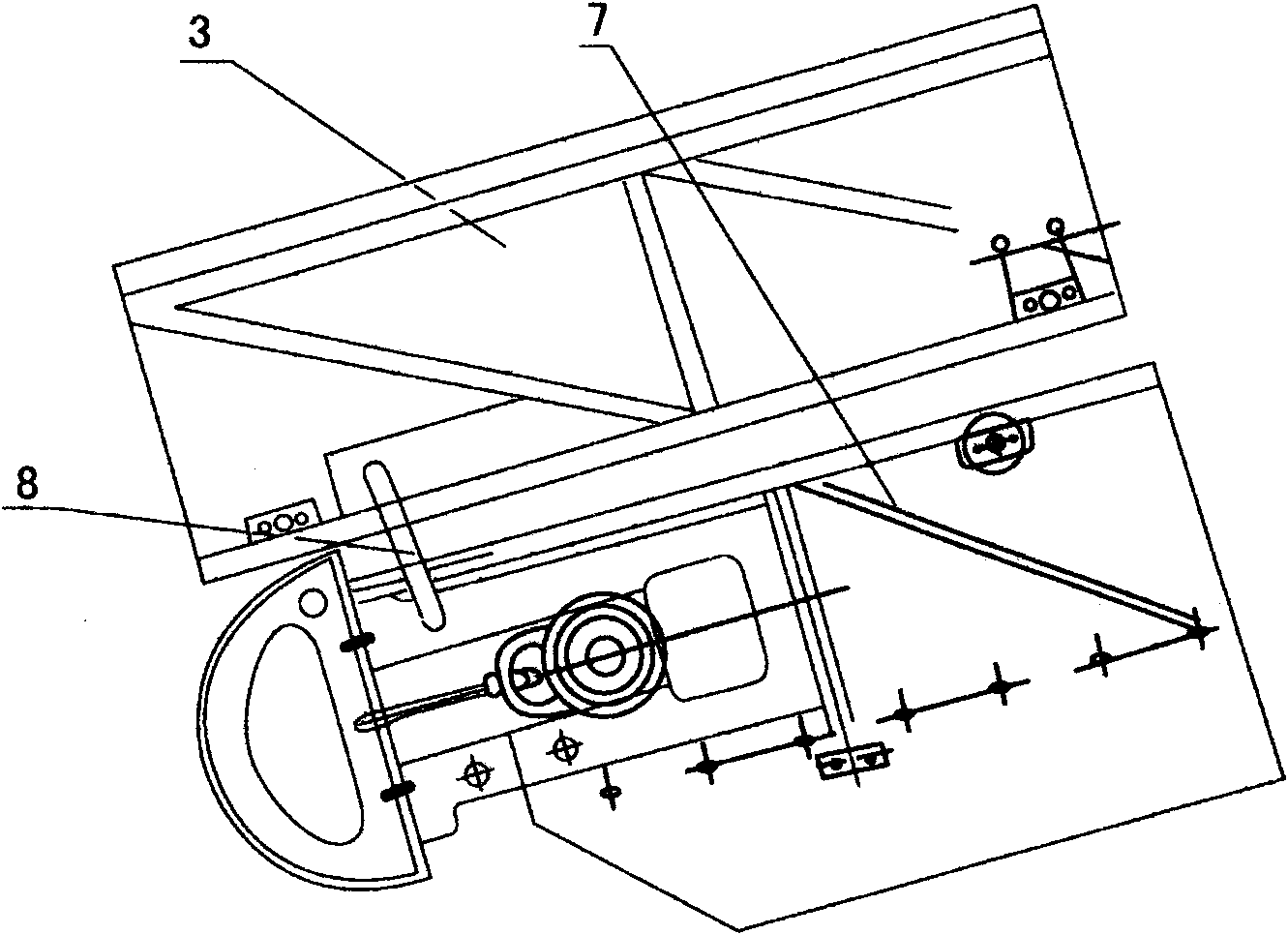

[0012] The invention is applied on a milling machine. see figure 1 . Mechanical folding discharge tape conveyor for milling machines. Including the front frame 3 that is connected to the milling machine in rotation, the rear frame 7 that is connected to the front frame 3 in rotation, the front frame 3 and the rear frame 7 are connected by the rotating shaft 6, the hydraulic cylinder 5 is hinged on the milling machine, and one end of the wire rope I1 is connected to the Hydraulic cylinder 5 is affixed, and the other end is affixed with front frame 3, and front frame 3, rear frame 7 both sides are correspondingly provided with fixing pin holes symmetrically, when the present invention is in working order, two fixed pin shafts 4 Insert into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com