Automatic drainage valve of pedestal pan and working method thereof

A technology of automatic drainage and working methods, which is applied in water supply devices, flushing equipment with water tanks, buildings, etc., can solve problems such as forgetting to flush, not flushing, and unstable induction, etc., to prolong power supply time, save electric energy, and reduce power consumption. Electrode small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

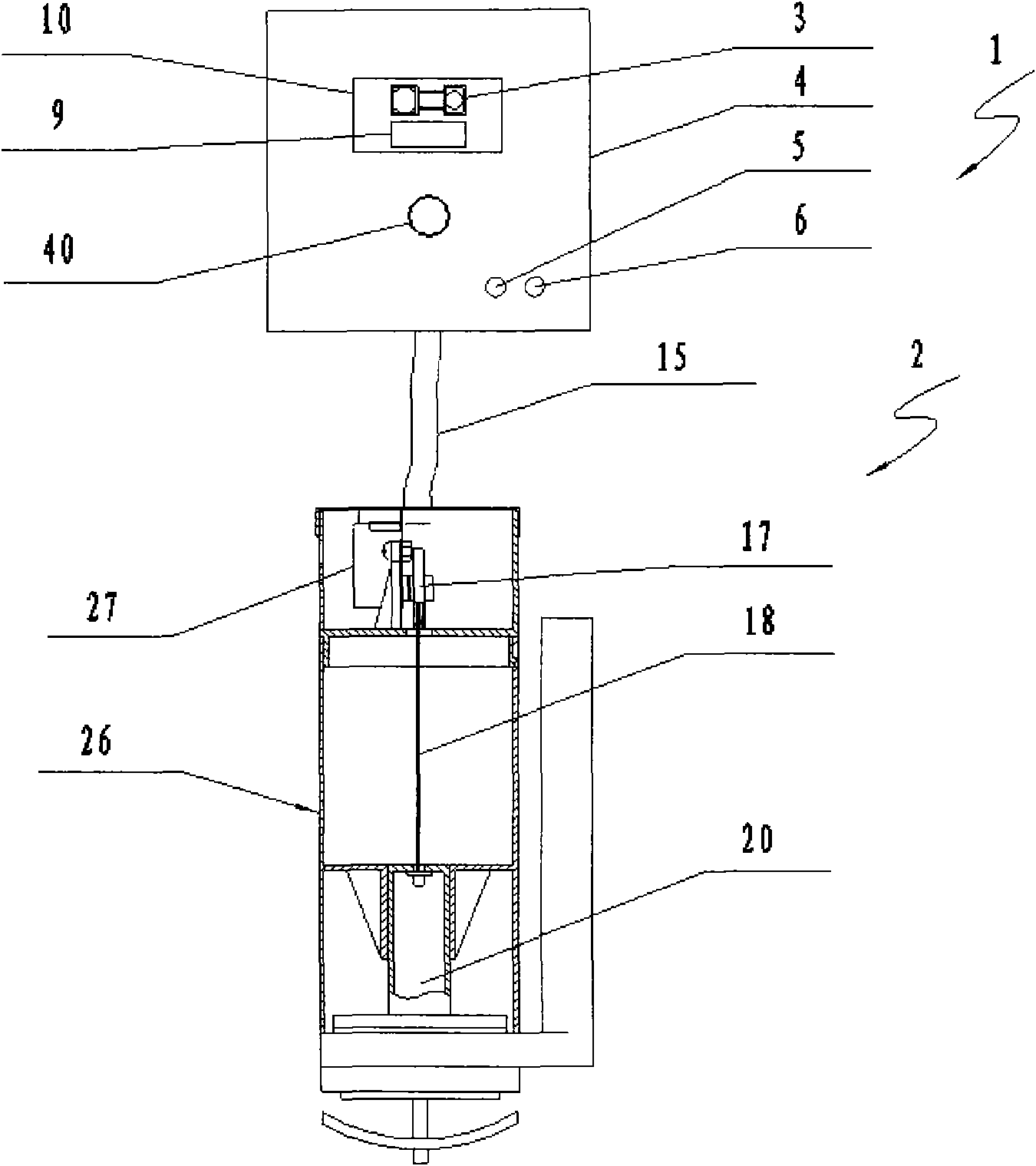

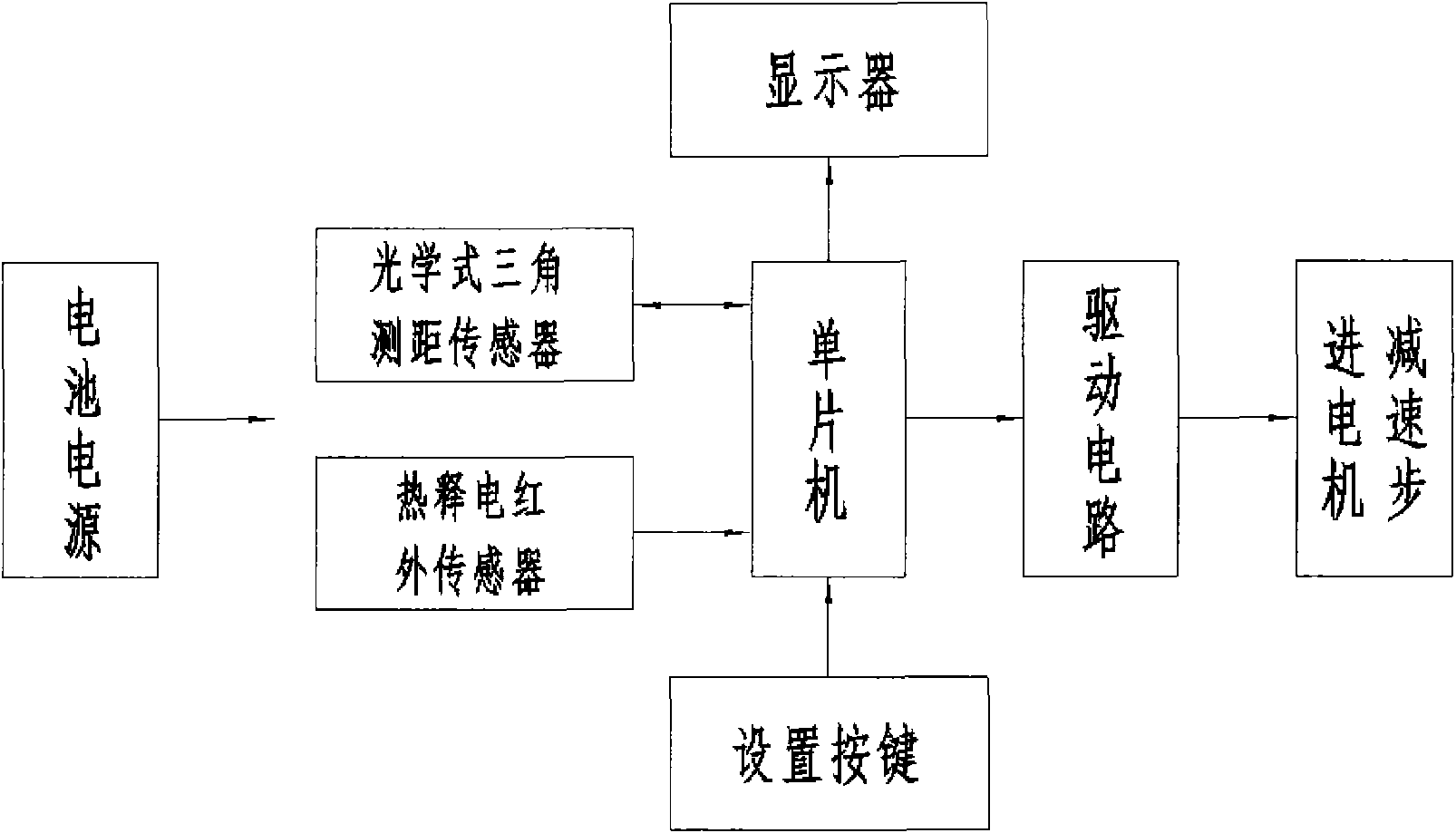

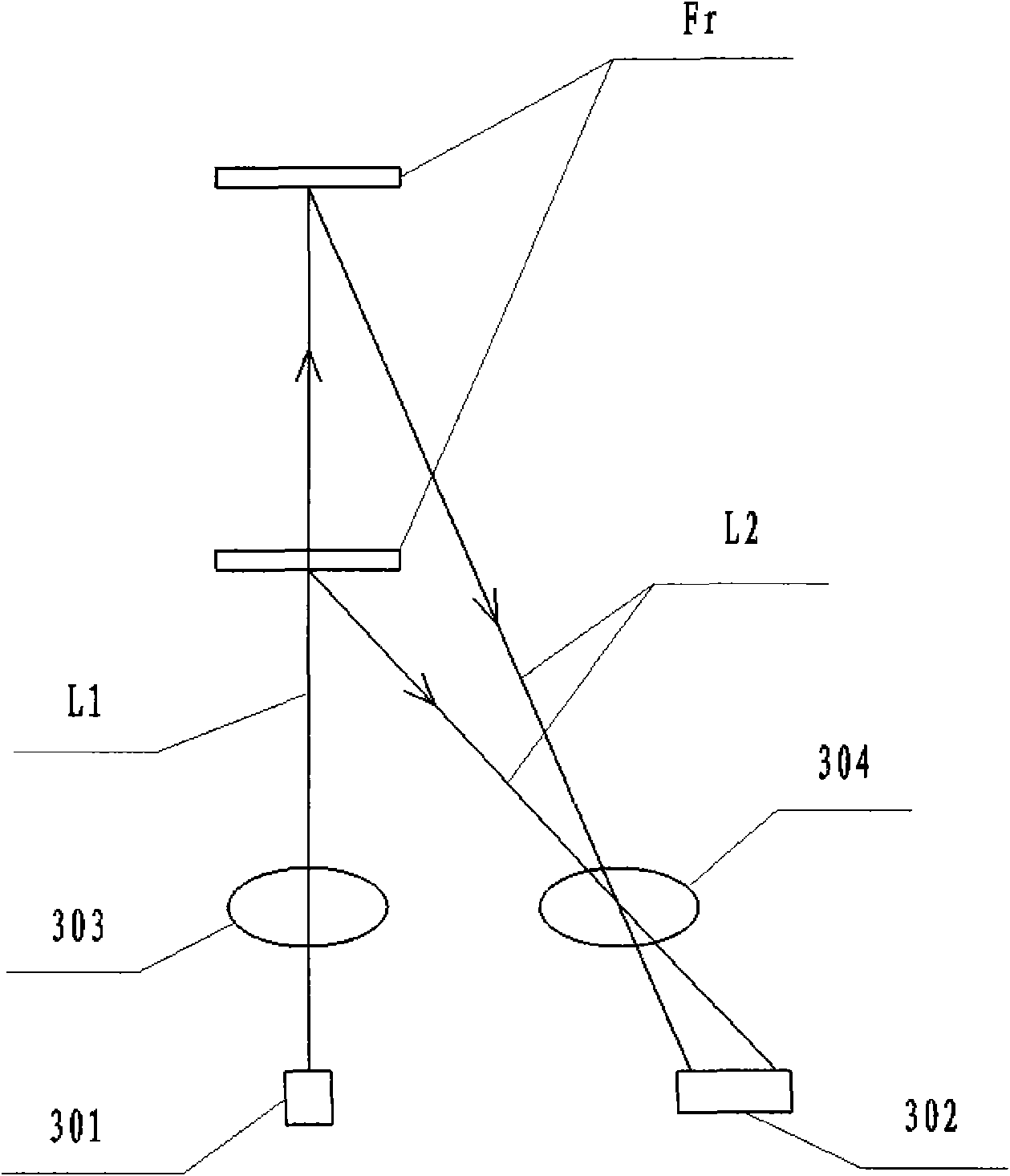

[0036] Example one, as Figure 1 to Figure 5 As shown, the controller 1 of the toilet automatic drain valve of this embodiment includes: an optical triangulation sensor 3, a pyroelectric infrared sensor 40, an output signal receiving the optical triangulation sensor, and a pyroelectric infrared sensor. A single-chip microcomputer for outputting and processing signals, a driving circuit controlled by the single-chip microcomputer, setting buttons 5 and 6 for setting values and functions, a display circuit 9 for displaying the setting content, a battery power supply, and a controller housing 4 with a wall fixed end, The controller shell is a surface-mounted structure that does not damage the wall. Among them, the optical triangulation ranging sensor includes: a light-emitting element that emits irradiation light, a light-emitting lens that focuses the irradiation light and irradiates the distance-measuring object, a light-receiving lens that collects the reflected light reflec...

Embodiment 2

[0050] Example two, as Figure 6 to Figure 11 As shown, the controller 1 of the toilet automatic drain valve of this embodiment includes: an optical triangulation sensor 3, a pyroelectric infrared sensor 40, an output signal receiving the optical triangulation sensor, and a pyroelectric infrared sensor. A single-chip microcomputer for outputting and processing signals, a wireless transmission circuit I for transmitting the instructions of the single-chip microcomputer, setting buttons 5 and 6 for setting values and functions, a display circuit for displaying setting contents, a controller housing 4 with a wall fixed end and providing control The battery power supply of the device power. The electric drain valve 2 includes: a wireless transmission circuit II for transmitting instructions of the single-chip microcomputer, a single-chip microcomputer II for receiving instructions from the single-chip microcomputer, a drive circuit driven by the single-chip microcomputer II, an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com