Indoor multilayer corrosion-proof and wear-resistant floor

A kind of anti-corrosion and wear-resistant flooring technology, which is applied in the direction of layered products, wood layered products, buildings, etc., can solve the problems of shortened floor life, human hazards, long duration, etc., and achieve the effect of durable use and beautiful texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in combination with specific embodiments.

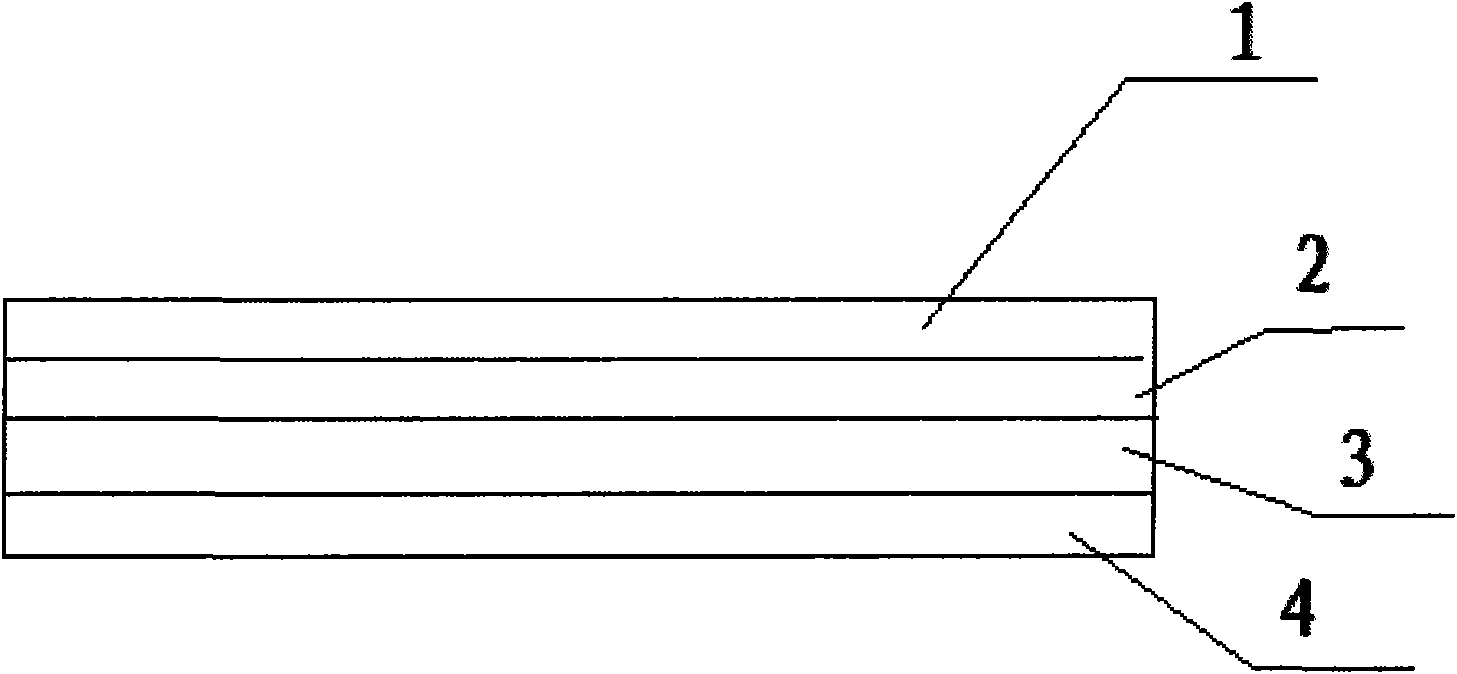

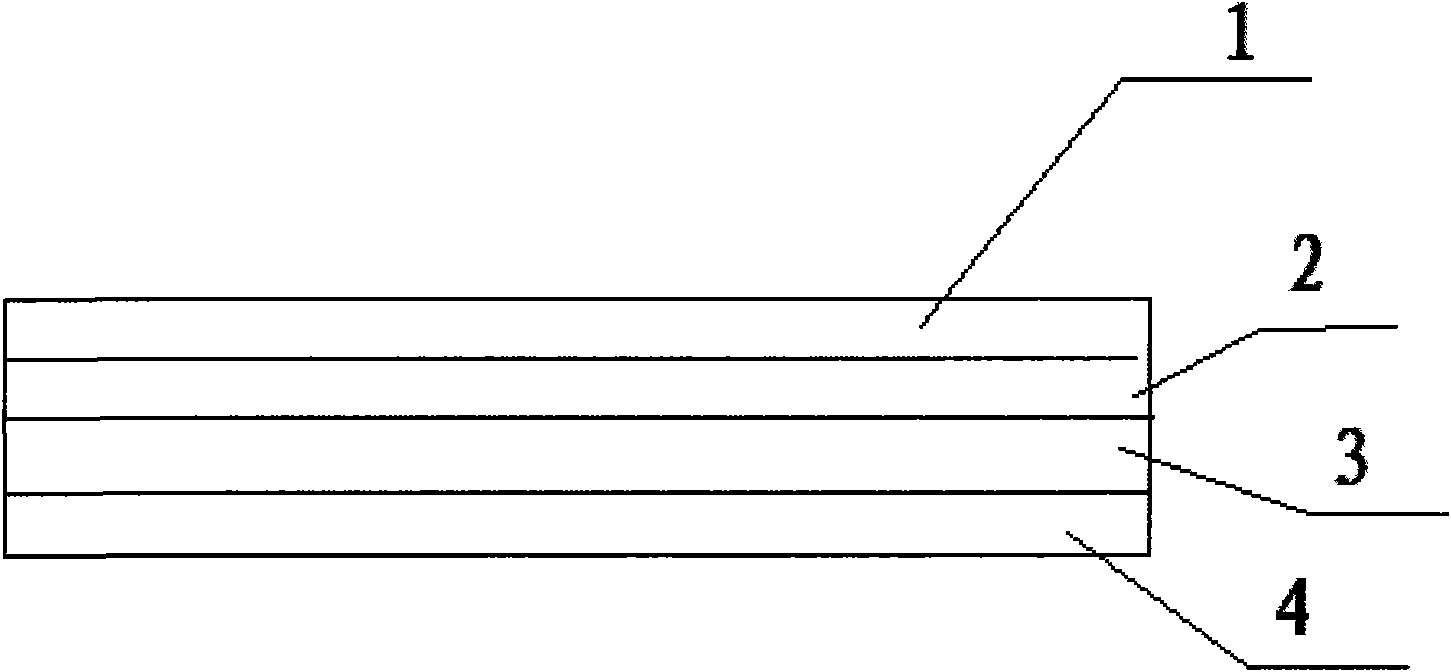

[0012] Referring to Figure 1, the indoor multi-layer anti-corrosion and wear-resistant floor includes an anti-corrosion layer 4, a buffer layer 3, a wooden layer 2 and a wear-resistant layer 1, wherein the anti-corrosion layer 4 and the buffer layer 3 are combined by hot pressing or adhesive The wooden layer 2 is hot-pressed on the buffer layer 3, and the wear-resistant layer 1 is hot-pressed on the wooden layer 2. The anti-corrosion layer is a PVC foam board; the buffer layer is a PVC hard low-foam board, and the anti-corrosion layer is aluminum oxide wear-resistant paper.

[0013] The above specific embodiments do not limit the technical solutions of the present invention in any form, and all technical solutions obtained by means of equivalent replacement or equivalent transformation fall within the scope of protection of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com