Integrated pneumatic design method of axial-flow turbine and single-side radial steam/gas discharging system

A technology of aerodynamic design and turbine, applied in the direction of machine/engine, mechanical equipment, engine components, etc., it can solve the problem that the performance of the turbine and the exhaust/gas system is quite different from the design value, regardless of the blade exhaust and exhaust/gas Air system aerodynamic interaction and other issues, to achieve the effect of reducing the degree of non-axisymmetric, increasing power output, and reducing back pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

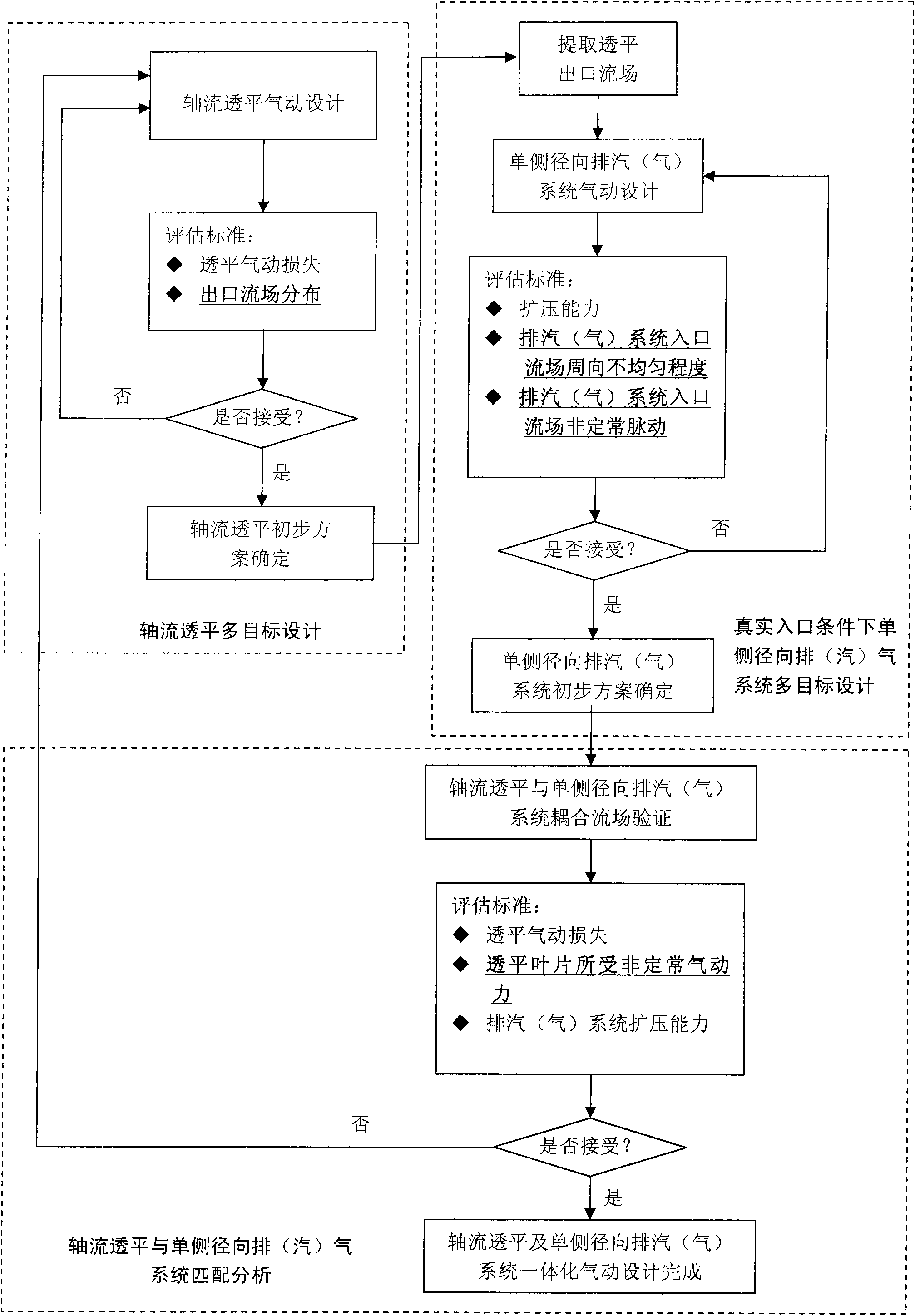

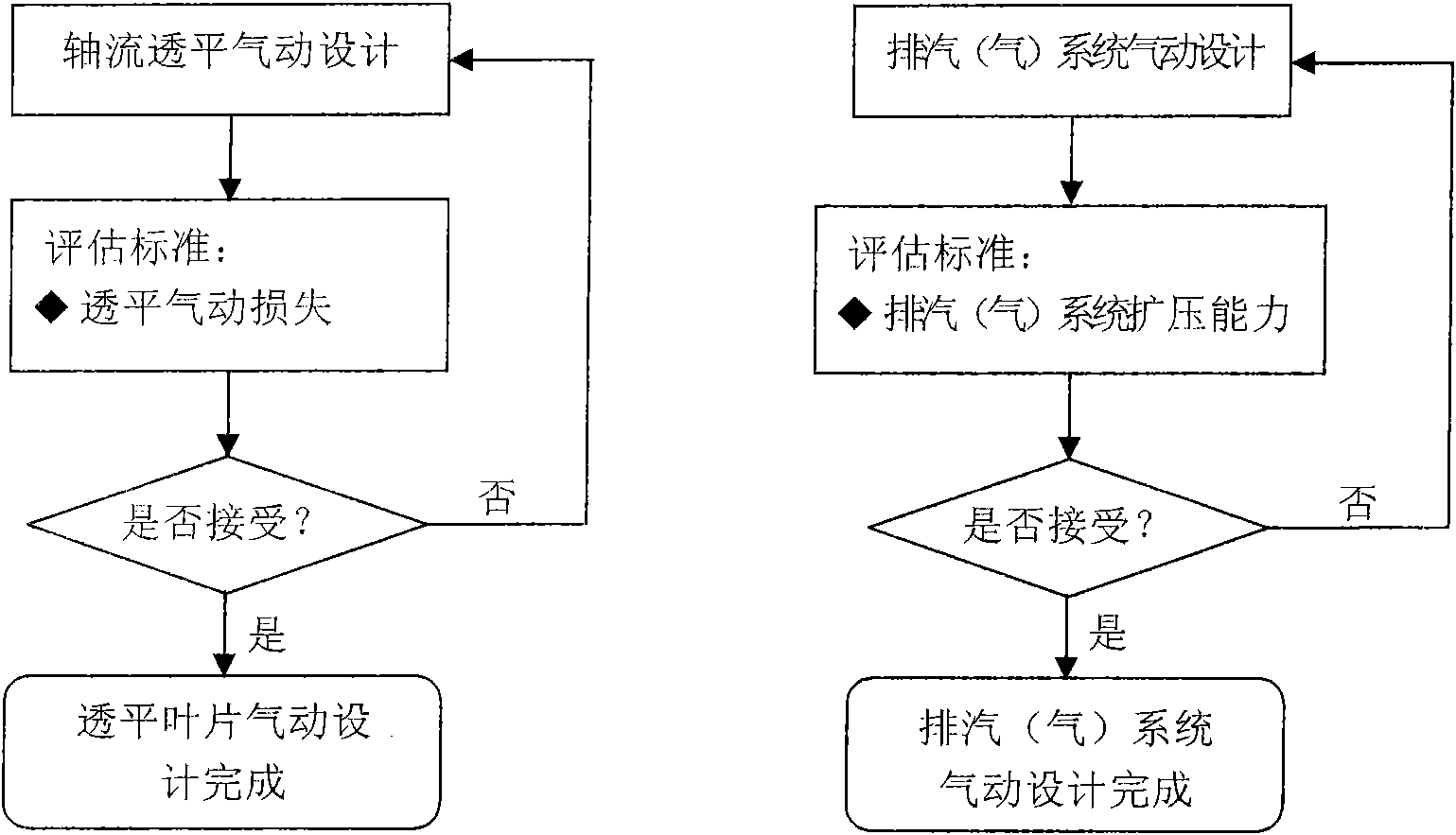

[0023] The integrated aerodynamic design method of the axial flow turbine and the unilateral radial exhaust / gas system of the present invention is based on the strong aerodynamic interaction between the turbine blade row and the unilateral radial exhaust / gas system. New aerodynamic design method. This design method proposes the integrated design of axial flow turbine and non-axisymmetric exhaust steam / gas system. In order to ensure that the exhaust steam / gas system has a good pressure expansion capacity under the actual operating environment, and to improve the operating safety of the turbine blades, the design is designed to improve the exhaust steam / gas system's ability to recover the residual speed kinetic energy at the final stage of the turbine. Reducing the non-axisymmetric degree of the turbine outlet flow field and reducing the pressure pulsation caused by the internal flow instability of the exhaust steam / gas system is the overall design goal. The turbine blade row and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com