Vehicle oxidation catalyst efficiency model for adaptive control and diagnostics

An oxidation catalyst, vehicle technology, applied in the direction of machines/engines, electronic control of exhaust treatment devices, mechanical equipment, etc., can solve problems such as increasing filter pressure difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

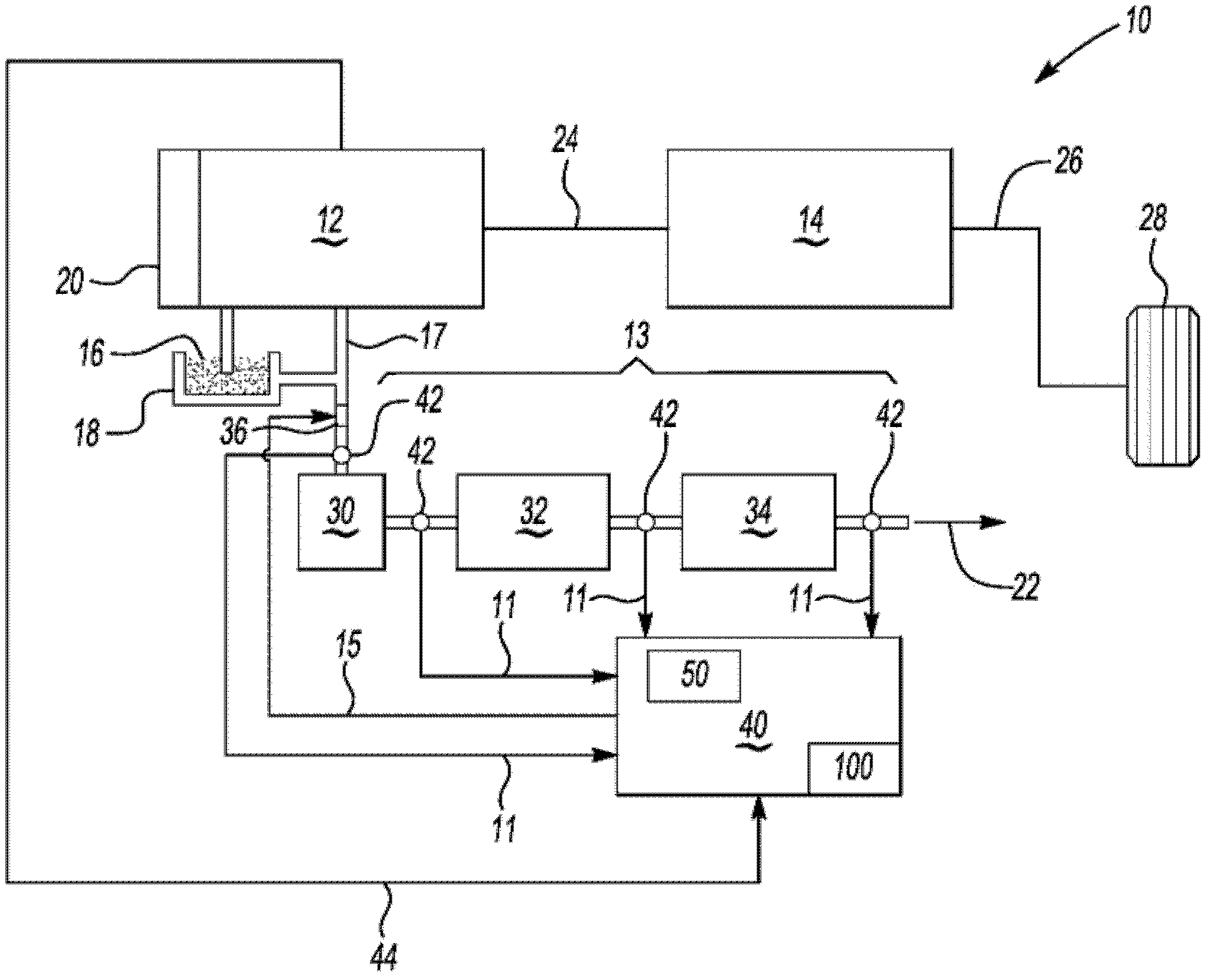

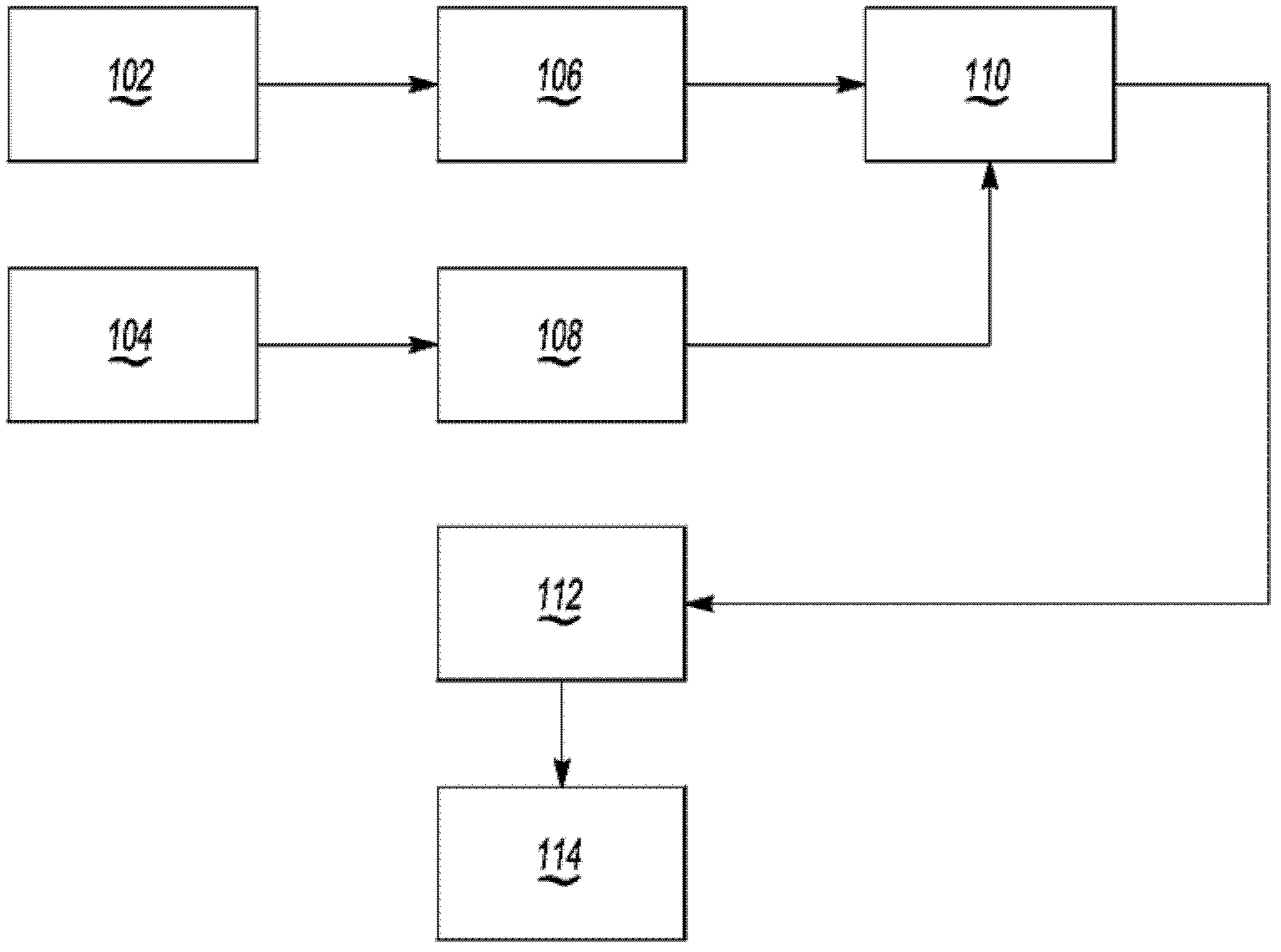

[0011] Referring to the drawings, wherein the same reference numerals in the several drawings correspond to the same or similar components, figure 1 A vehicle 10 is schematically shown in . The vehicle 10 includes a host computer 40 and a diagnostic algorithm 100 that is selectively executed by the host computer 40 to calculate the actual conversion efficiency of an oxidation control (OC) system 13 onboard the vehicle 10 . The host computer 40 can thus be used to calculate, evaluate and control the actual level of hydrocarbons ultimately emitted by the vehicle 10 into the surrounding atmosphere, which can be achieved by using the referenced figure 2 The temperature model 50 described in more detail is completed in part.

[0012] The vehicle 10 includes an internal combustion engine 12 such as a diesel engine or a direct injection gasoline engine, an OC system 13 and a transmission 14 . The engine 12 combusts fuel 16 drawn from a fuel tank 18 . In one possible embodiment, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com