Injection jet engine

A jet engine and power technology, applied in the direction of ramjet engine, combined engine, machine/engine, etc., can solve the problems of engine use, complex structure, fast running speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

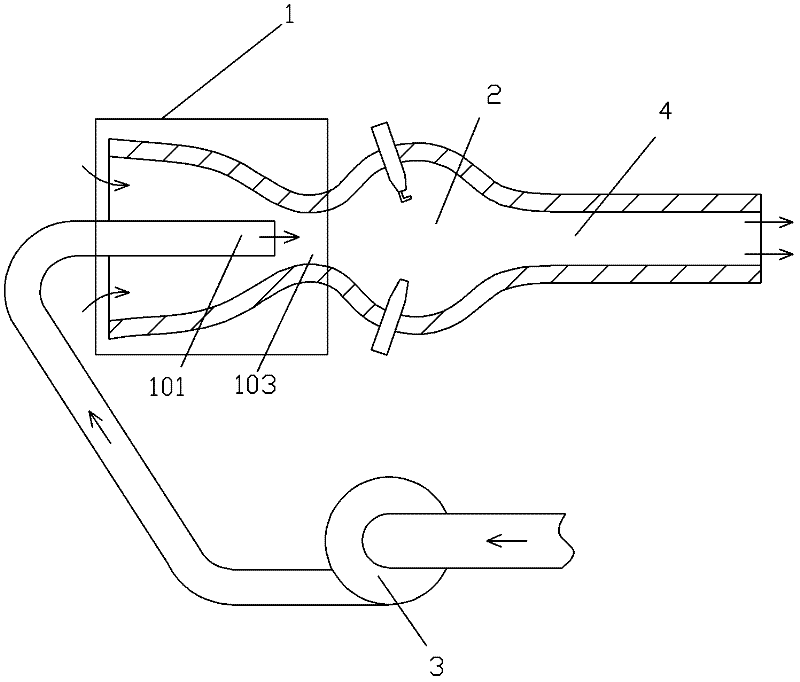

Embodiment 1

[0095] Such as figure 1 The jet jet engine shown includes a jet pump 1, a combustion chamber 2 and a high-pressure pump 3, the jet pump outlet 103 of the jet pump 1 communicates with the combustion chamber 2, and the gas working medium outlet of the combustion chamber 2 communicates with the combustion chamber 2. The injection channel 4 communicates, and the fluid outlet of the high-pressure pump 3 communicates with the motive fluid nozzle 101 of the jet pump 1 . The power fluid pressurized by the high-pressure pump 3 is ejected by the jet pump 1 and then reacts with the fuel in the combustion chamber 2 to form a high-temperature and high-pressure working fluid. The ejection channel 4 ejects to obtain propulsion.

[0096] In order to make the ejection jet engine work more efficiently and environmentally friendly, adjust the pressure of the gas working medium that is about to start working to more than 15MPa, and adjust the temperature of the gas working medium that is about ...

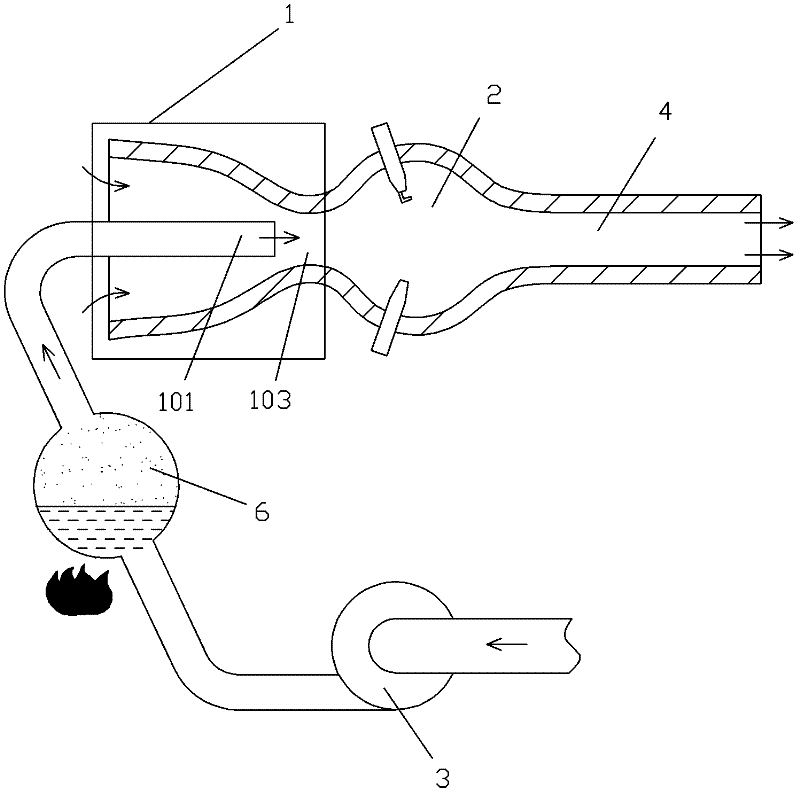

Embodiment 2

[0098] Such as figure 2 The difference between the shown ejection jet engine and Embodiment 1 is that a carburetor 6 is provided between the high-pressure pump 3 and the motive fluid nozzle 101 . The liquid working medium in the vaporizer 6 is a gas liquefaction. The working process of this scheme is: first use the high-pressure pump 3 to pressurize the liquid in the vaporizer 6, then heat the vaporizer 6 to vaporize the liquid therein into high-pressure steam, and the high-pressure steam enters the jet pump as a motive fluid to work. That is, this solution provides another method for generating high-pressure motive fluid.

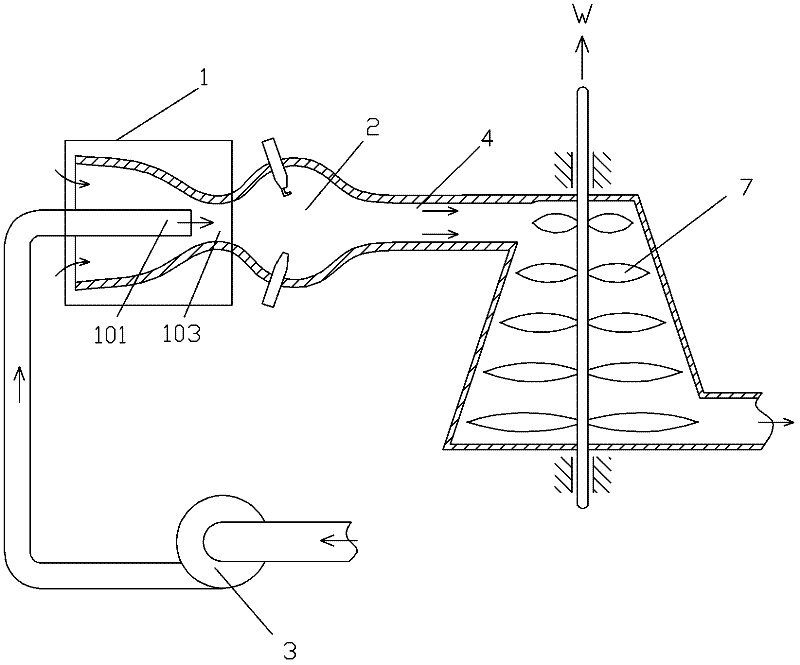

Embodiment 3

[0100] Such as image 3 The difference between the shown ejection jet engine and Embodiment 1 is that a power turbine 7 is provided at the injection port of the injection channel 4 .

[0101] During specific implementation, a power turbine 7 may also be provided in the injection channel 4 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap