Quick joint

A fast, on-body technology, applied in the direction of mechanical equipment, couplings, etc., can solve problems such as pipe swinging, injury to operators, and connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

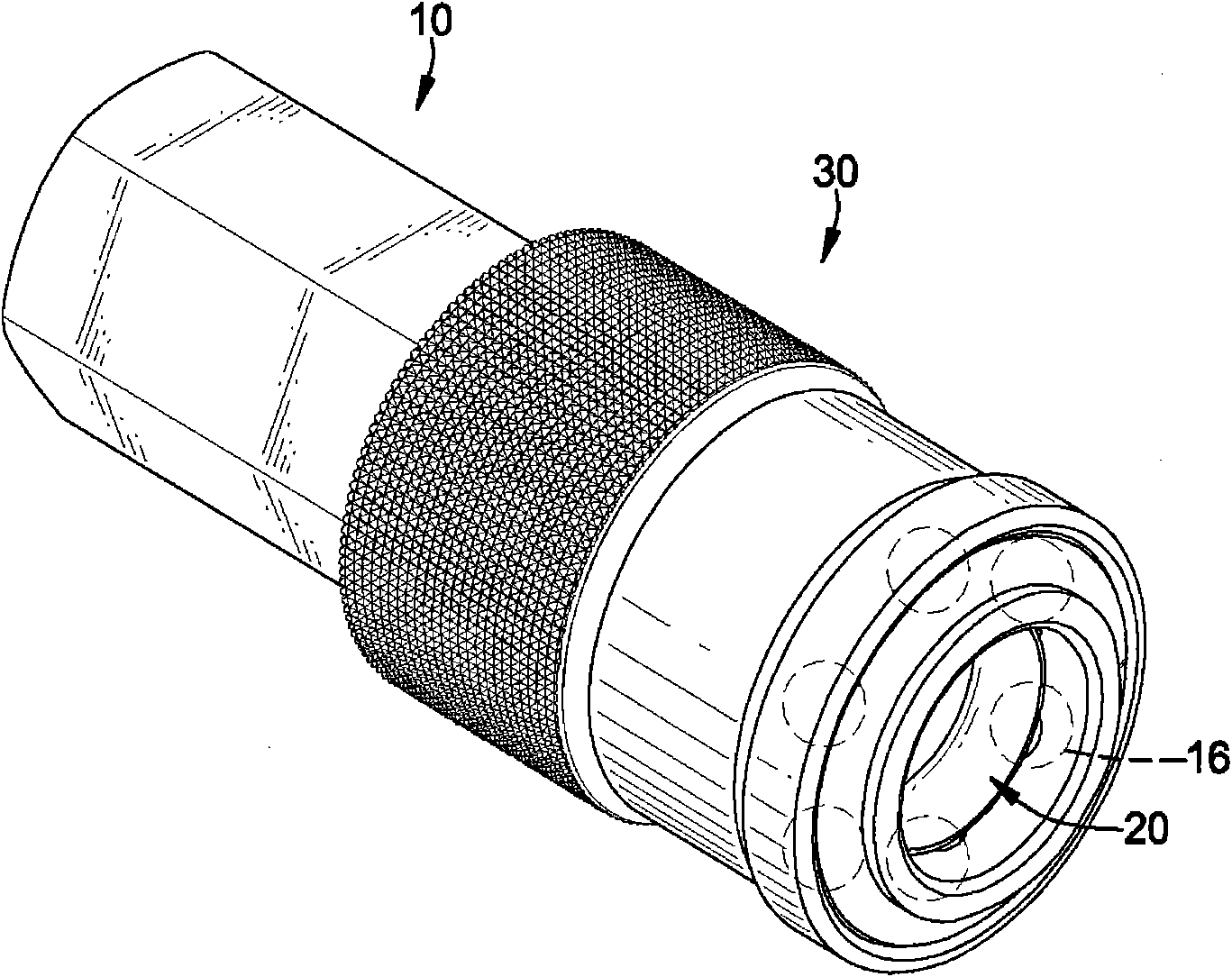

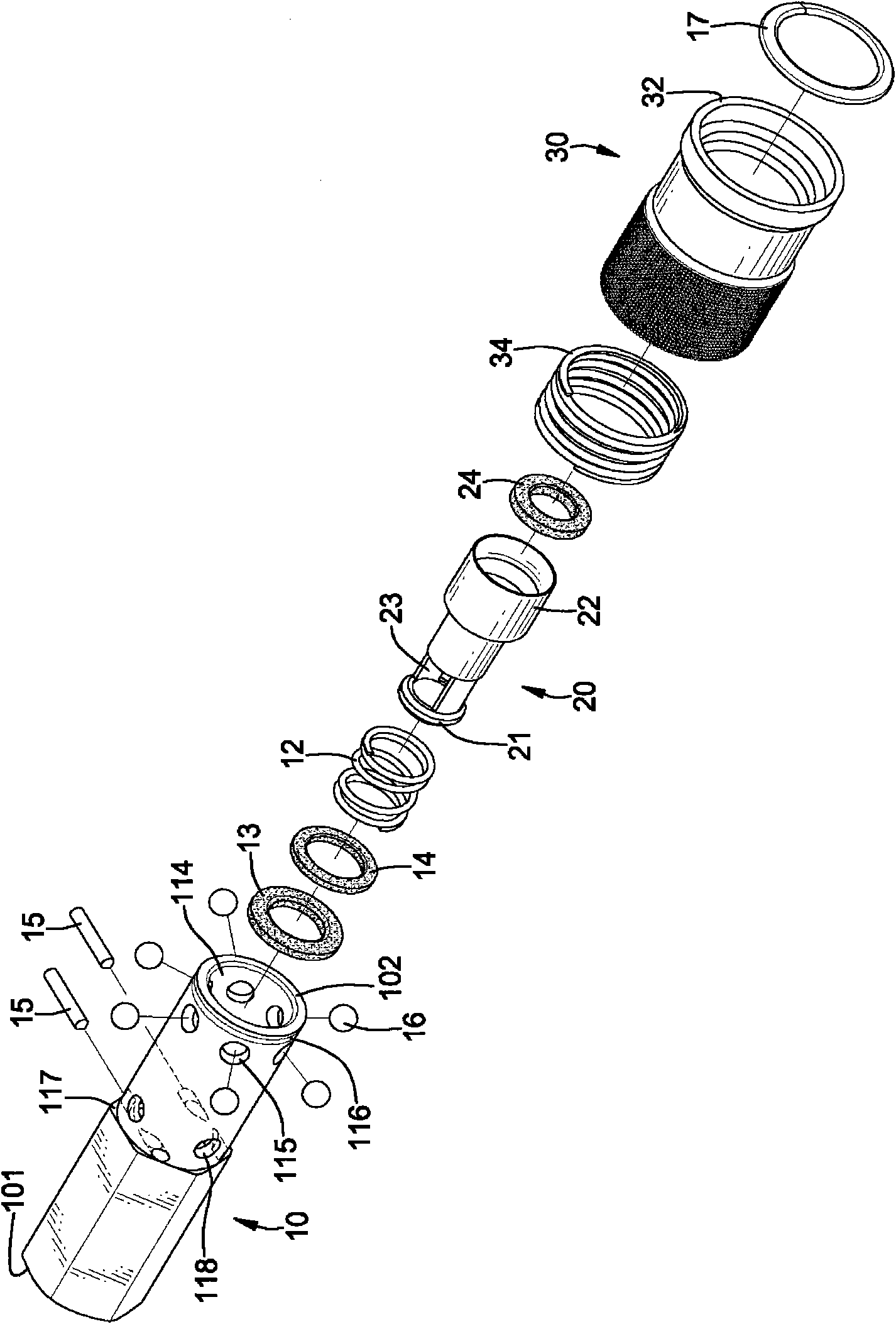

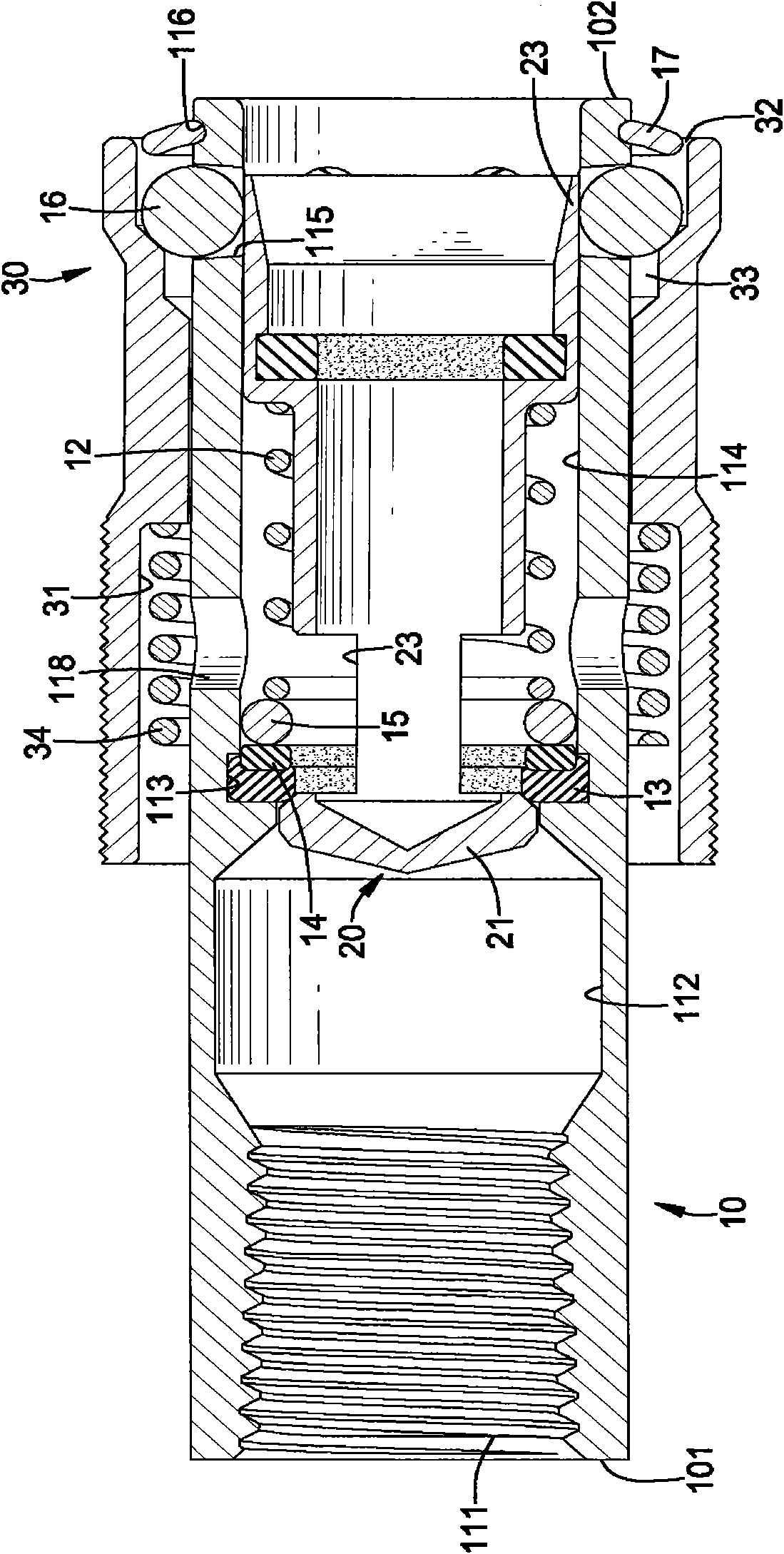

[0052] In order to understand the technical features and practical effects of the present invention in detail, and to implement them according to the contents of the description, the preferred embodiment shown in the drawings is further detailed as follows, please refer to the following Figures 1 to 4 As shown, the quick connector (Japanese standard) of the present invention is provided with a body 10, a valve seat 20 and an outer casing 30, wherein:

[0053] The body 10 is an integrally formed hollow cylinder and is provided with a joint end 101 and a positioning end 102, wherein the joint end 101 of the body 10 is used to combine with an air compressor (not shown), as image 3 or Figure 8AAs shown, the body 10 is provided with a screw thread 111 on the inner surface or the outer surface near the coupling end 101, and the body 10 is provided with an air inlet chamber 112 connected with the air compressor, an inner diameter A locking groove 113 smaller than the air inlet ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com